© 2021 ICS®, Oregon Tool Inc. REV12232021 P/N 610794

536-E OPERATOR MANUAL

34

ENGLI SH

Operation

IMPORTANT

SYSTEM CLEAN-UP

• After cutting, run the power cutter for at least 15 seconds with the water on to

flush slurry and debris from diamond chain, guidebar and drive sprocket

•

•

water. Lubricate tensioner with waterproof grease

• After cleaning the power cutter, spray the entire power cutter body, chain,

power cutter will minimize rust and help reduce slurry build up

AFTER EACH USE

• Inspect drive sprocket for wear

the tops of the sprocket teeth

• Inspect and tighten all fasteners as necessary

•

•

• Check guidebar and chain for damage or excessive wear.

• Parts with damage or excessive wear should not be used or repaired, they should

be replaced.

•

or damage.

• If storing in temperatures below freezing, be sure use compressed air to blow out

all water from the tool.

Power Cutter side

Shaft sling

labyrinth

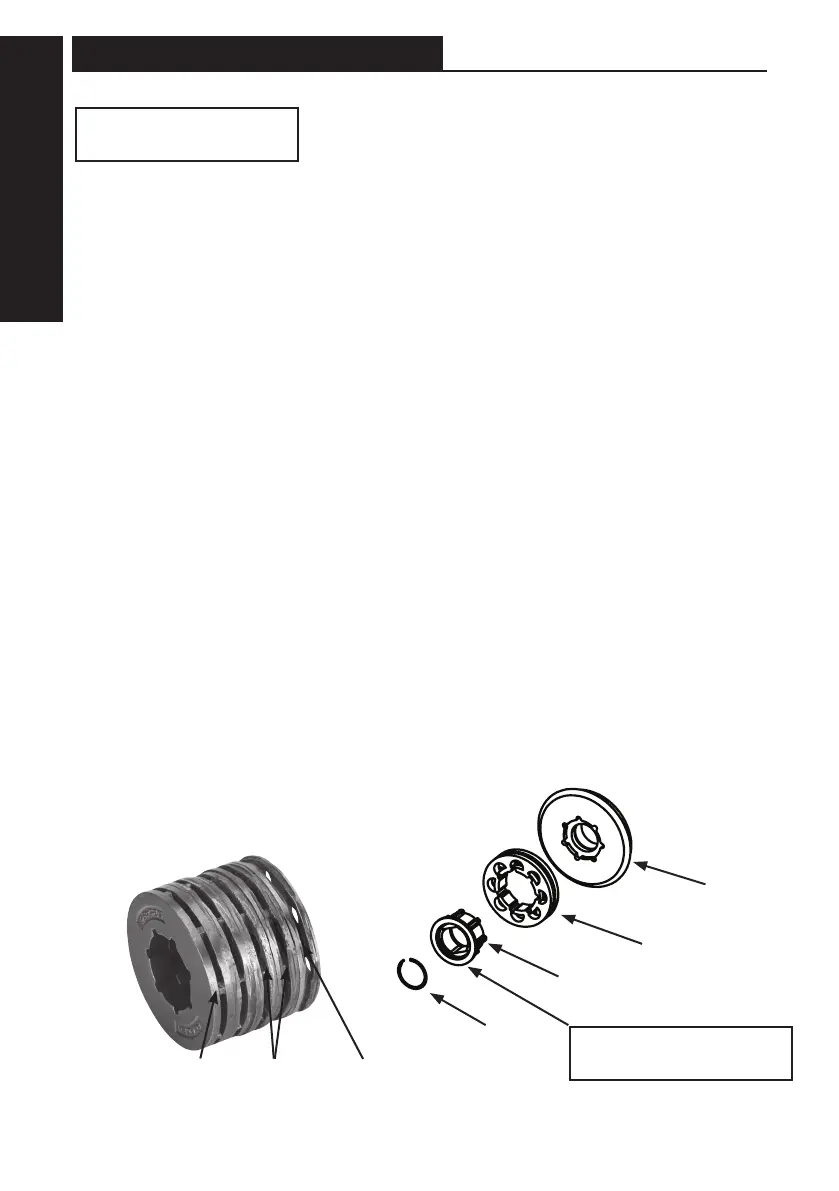

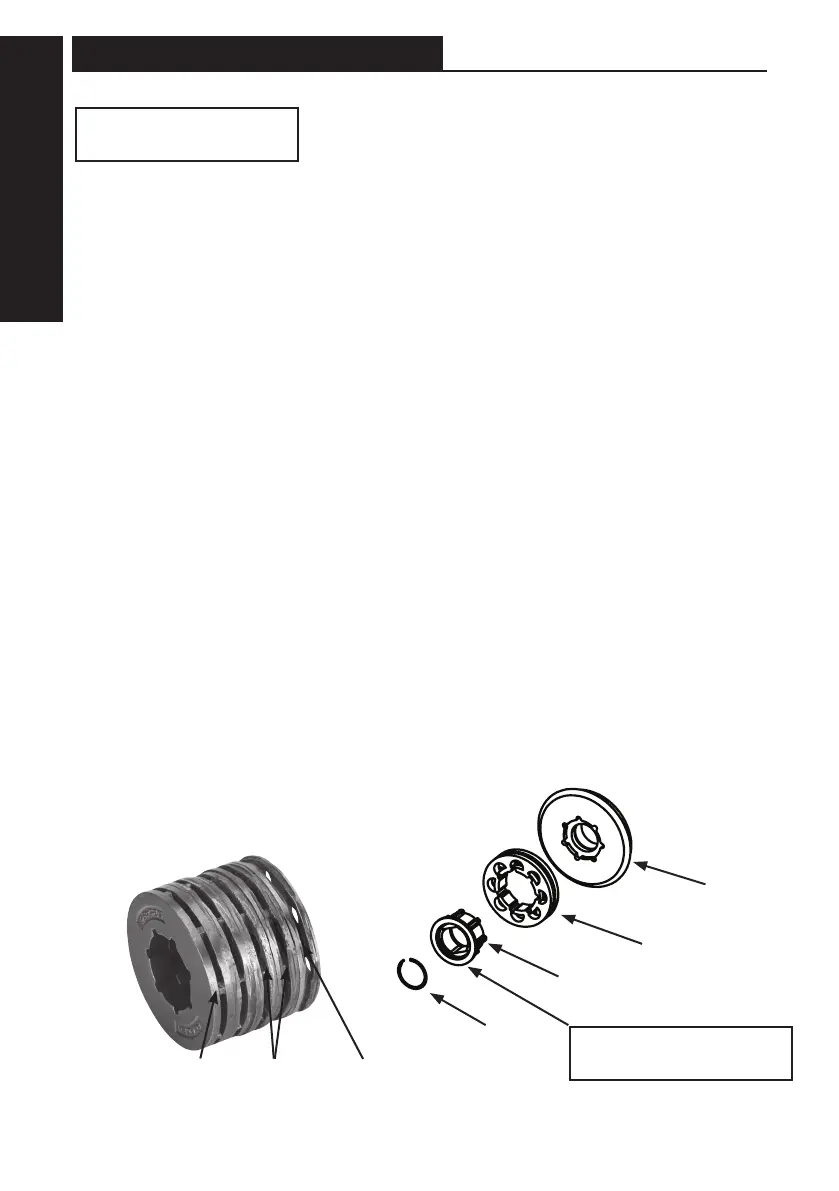

Drive

Sprocket

Spline

Adaptor

Snap Ring

Flanged side facing out

IMPORTANT

• The drive sprocket is a wear item and

should be replaced every two to three

chains, or when the teeth become

pointed or if a groove cuts through top

of tooth.

• Inspect the sprocket for wear.

• Inspect drive shaft for wear.

DRIVE SPROCKET

replacing

Loading...

Loading...