680ES OPERATOR MANUAL

38

© 2015 ICS®, Blount International Inc. Specications are subject to

change without notice. REV071315 F/N 577451

Maintenance

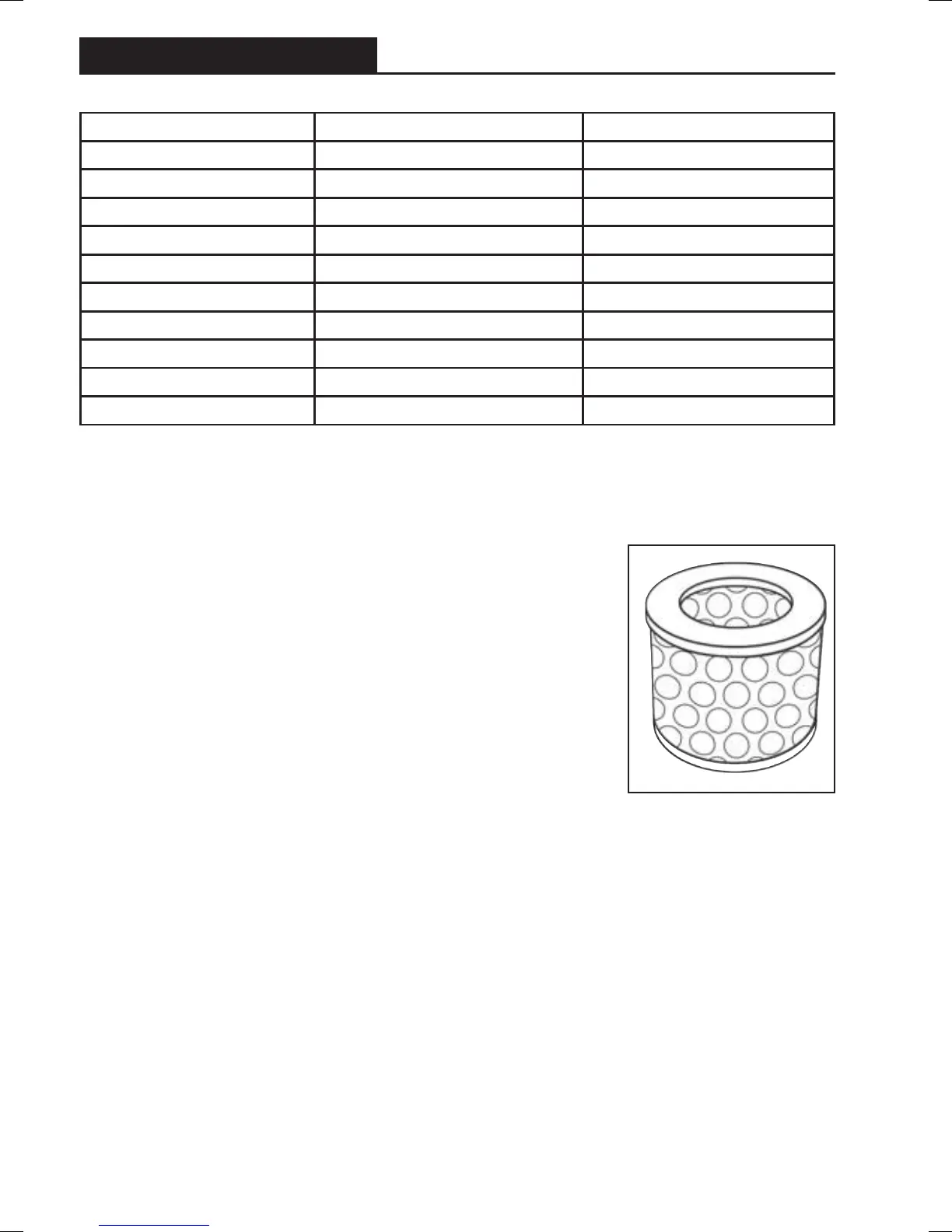

AIR FILTER

The polyester air lter must be kept clean for the

engine to operate properly. If the saw is not reaching full RPM, most likely the air

lter is dirty or wet.

• The air lter should be free of holes and white in color

• Replace the air lter when dirty or wet.

• When replacing the air lter, clean the area inside the air

box with a clean towel prior to installing new lter

• Inspect air box seal for wear or damage. Replace if

damaged.

FUEL SYSTEM

• Clean area around fuel cap before removing.

• Check the fuel cap and seal for damage.

• Check the fuel line for damage.

• Check fuel lter, assure it is free of debris.

• Replace fuel lter if it is stained dark or clogged (fuel lter cannot be cleaned).

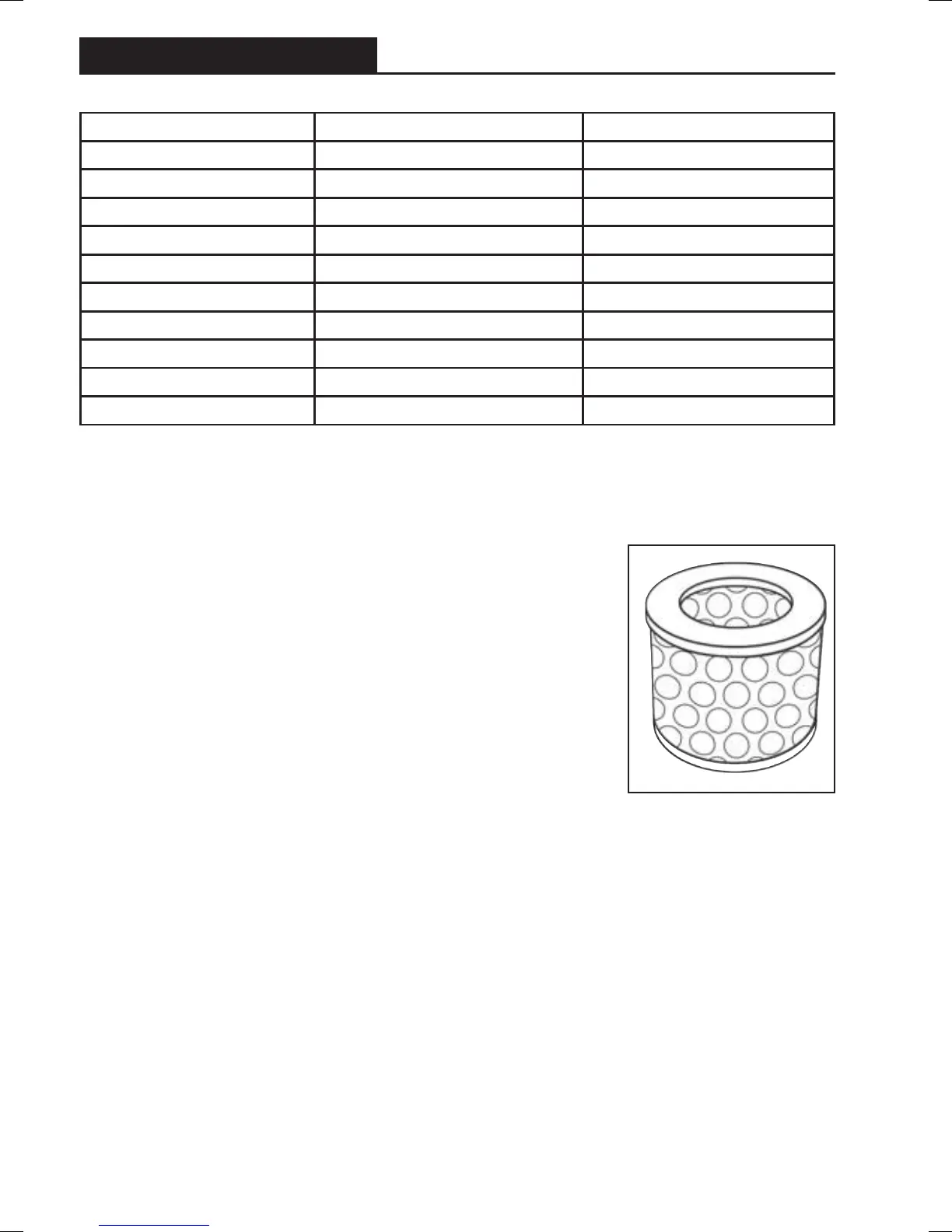

After each use After every 10 hours After every 40 hours

External Cleaning Clean Starter Housing Replace Spark Plug

Fasteners/Screws Check Spark Plug Check Fuel Filter

Air Intake

Functional Inspection Functional Inspection Functional Inspection

General Inspection Vibration Isolators Fuel System

Throttle Trigger Lockout Muer Fuel Filter

Multi-function Lever Carburetor Air Filter

Mud Flap Starter Housing Clutch Cup

Guidebar and Chain Sprocket Clutch

Loading...

Loading...