35

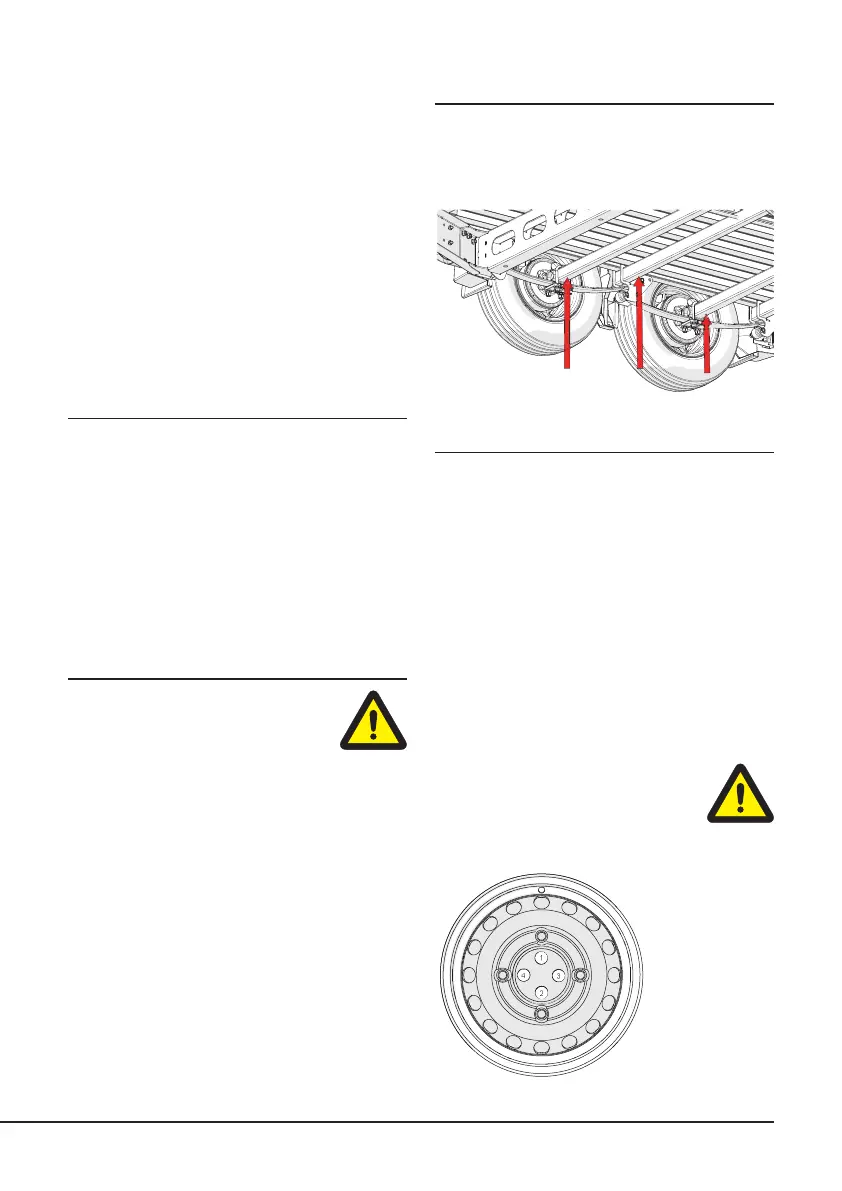

9.2.3 FITTING WHEELS

• Ensure wheel bolt threads and wheel

seating surfaces are clean and dry.

• Place wheel over locating rim on the hub.

• Tighten each bolt slightly and then tighten

to the torque figure given below, following

the sequence shown in the diagram to

the right.

Bolt size: 4 x M12

Torque: 88Nm

Socket size: 19mm A/F

Wheel bolts should be checked

after the first 25 miles/40km of

service and subsequently before

every journey.

DO NOT REPLACE WITH LOWER

RATED TYRES

The maximum gross weight figure given on

the trailer plate is always equal to or less than

the approved maximum load for the tyres

multiplied by the number of tyres on the

trailer. In some cases, this includes a bonus

load which is allowed for trailer use up to

60mph. Other maximum load figures are

marked on some tyres. These do not apply to

the UK or Europe and should be disregarded.

9.1.1 TYRE REPAIRS

Punctures should be inspected and repaired

by a specialist tyre distributor. Do not fit

tubes to tubeless tyres as this can lead

to a “blow out” in the event of a further

puncture. If the tyre is too severely damaged

for a repair to be carried out the tyre should

be replaced.

9.2 CHANGING A WHEEL

9.2.1 JACKING UP THE TRAILER

DON’TS:

• Don’t place the jack on the centre

line of the trailer under axles or chassis

cross members.

• Don’t place the jack directly under the

bodywork edges, mudguards, front/rear

bumpers or the floor.

• Don’t place the jack under the suspension

springs.

• Don’t place the jack under the drawbars.

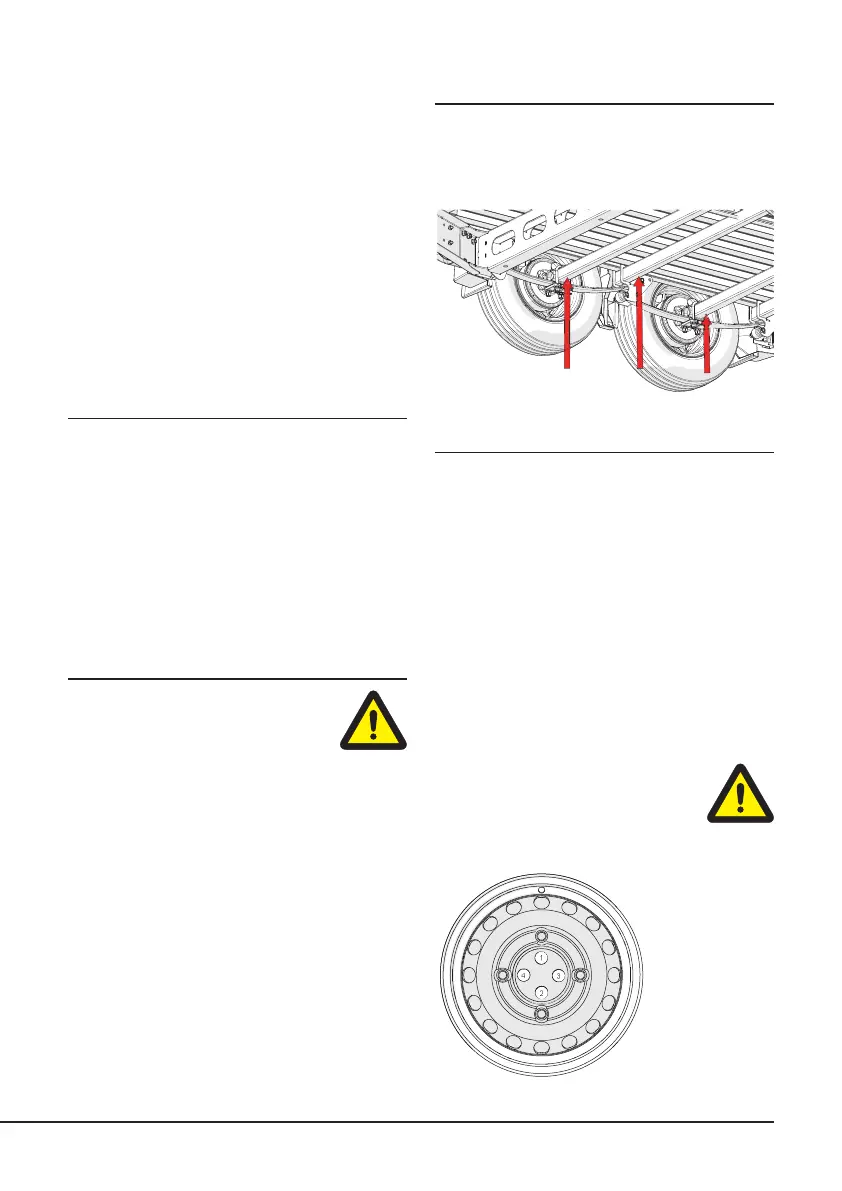

9.2.2 JACKING POINTS

1. Outer ends of the axles beside the springs.

2. Outer ends of the chassis cross members

beside the chassis rails.

1

4

2

3

Loading...

Loading...