1903KITINT18_230 – 1903KITINT18_400 (E121001A_ENG) 26/10/2012

6

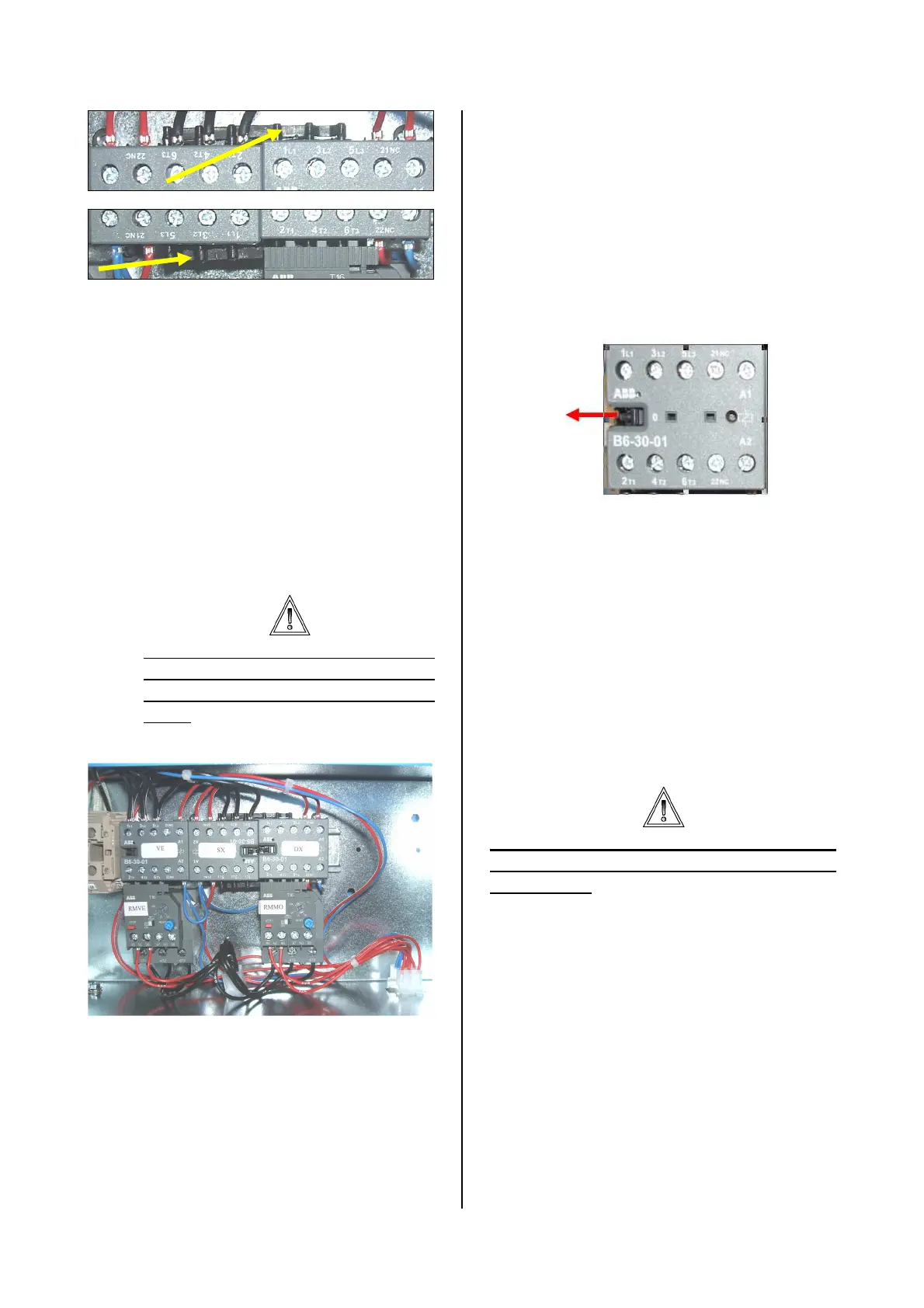

e) Install the motor thermal on the

terminals T1-T2-T3 of the

contactor DX. The previously

installed equipotential bar must be

clamped.

f) Install the wiring code T110609X

(supplied), which replace comletely

the previous wiring limited to the

contactor VE. The wiring is

provided with a 9 poles white

connector which can receive and

send signal to the control board on

the machine front.

The CABLE-TERMINAL

correspondence is highlighted in

the electrical diagram of the last

page.

g) Insert the three terminals of the

T110301X motor wiring (supplied)

into the three free places of the 6

poles white connector. The 6 poles

connectors is on the bottom of the

electric box. The cable position

coming from the motor can be

casual.

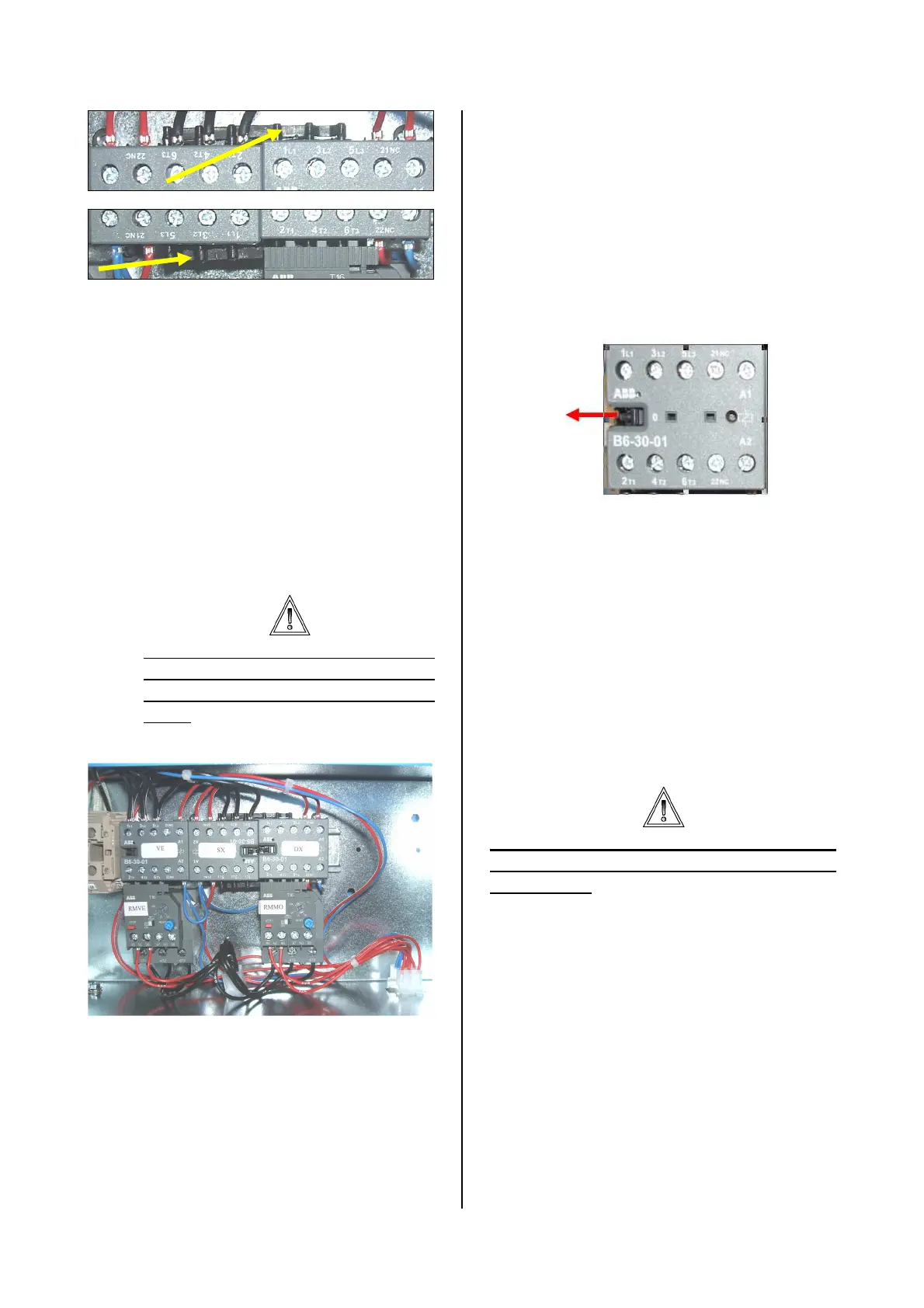

7. WORKING TEST

Each single contactor can be tested.

Using a screwdriver, push the pin until the

contact is completely closed. In this

situation, check the correct sense of

rotation and, if necessary, invert the two

phase in output.

.

8. THERMAL MOTOR ADJUSTMENT

To protect the fan and drum motor, the

two thermal relays must be set to a

threshold equal to the motor nominal

current.

To adjust the thermal devices, use the

small wheel of each device.

Using an ammeter control the current

absorbed from each motor, then set the

thermal to the value measured.

Do not set the thermal relay to the

maximum of its capacity: motors

could burn.

For a correct working, be sure that all the

three phases are correctly connected to

the drum motor with the nominal tension

of the electric system.

Loading...

Loading...