8

General information

1.7 WATER TREATMENT

Treating the supply water allows you to prevent

problems and maintain the functionality and

eciency of the generator over time.

e ideal pH value of the water in the central heating

system must be:

VALUE MIN MAX

PH 6,5 8

HARDNESS (°fr) 9 15

To minimise corrosion, it is essential to use a corrosion

inhibitor. In order for it to work eciently, the metal

surfaces must be clean.

ATTENTION!

Any damage caused to the boiler, due to the formation

of build-up or corrosive water, will not be covered by

the warranty.

ATTENTION!

e models only equipped with central heating are

NOT suitable for hot water production for human

consumption (M.D. 174/2004).

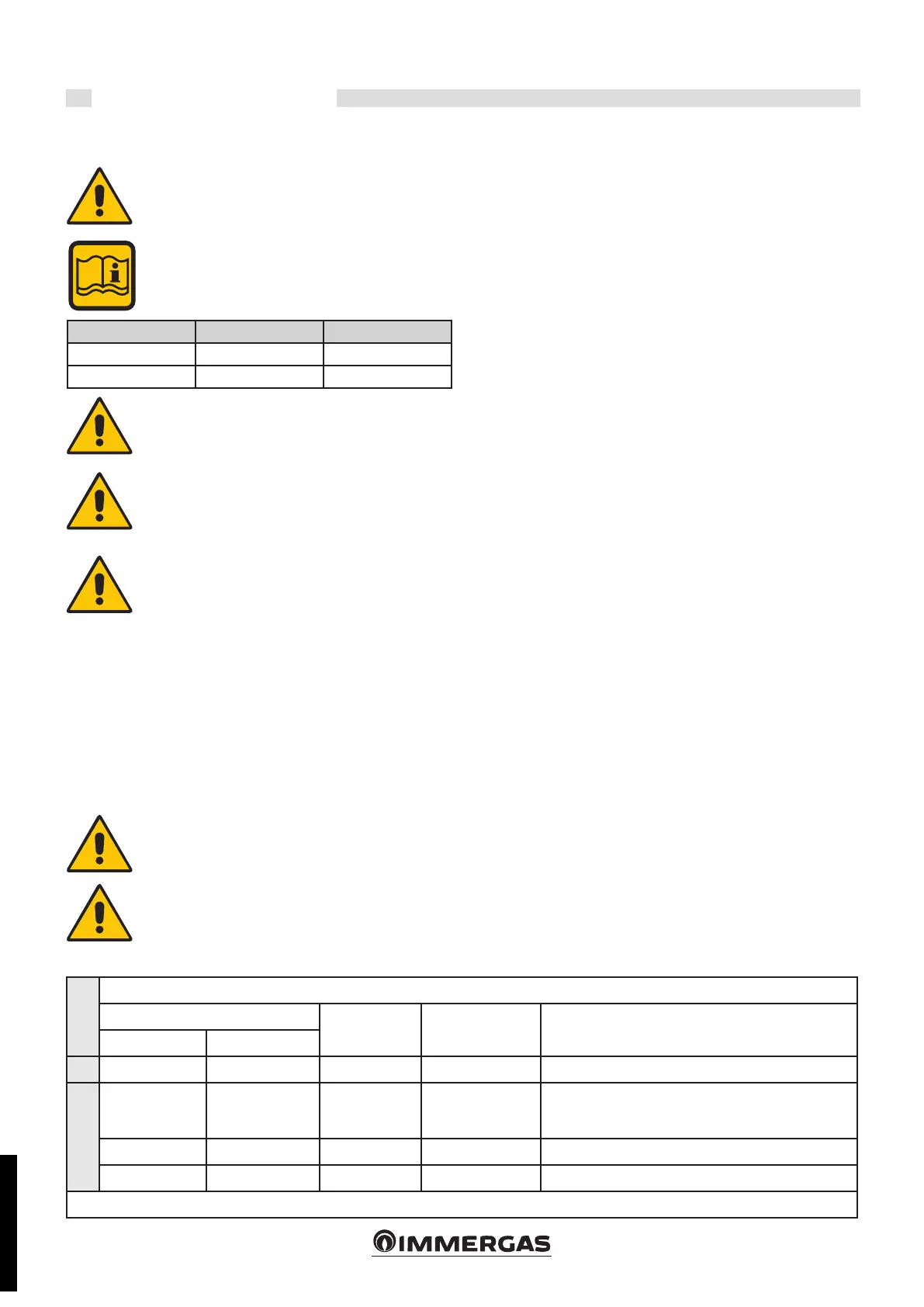

1.8 BOILER FROST PROTECTION

Activated by default

is protection only cuts in when the electric and gas supply are present.

If the electric or gas supply are disconnected and 11 (SM) detects a

temperature of between 2 and 5°C when the supply is restored, the

appliance responds as indicated in the table below, in pos.2.

Antifreeze products with an inhibitor for central

heating systems (specic for multimetal) can be used

to ensure ecient protection of the central heating

against freezing.

Do not use antifreeze products for car engines since

these can damage the water gaskets.

POS

ANTIFREEZE FUNCTION

Supply

11 - SR (*)

Status of antifreeze

function

Actions

Electric Gas

1 ON ON < 7°C ON Burner and Pump ON until T > 15°C

2

ON OFF < 5 ÷ 5°C OFF

INDICATION OF FAULT CODE 16

(see Par. 4.4 ERROR CODES).

Ignition inhibited.

OFF ON OFF Ignition inhibited.

OFF OFF OFF Ignition inhibited.

(*) SR sensor, see Par. 2.2

STD.006533/003

Loading...

Loading...