35

INSTALLERUSER

MAINTENANCE TECHNICIAN

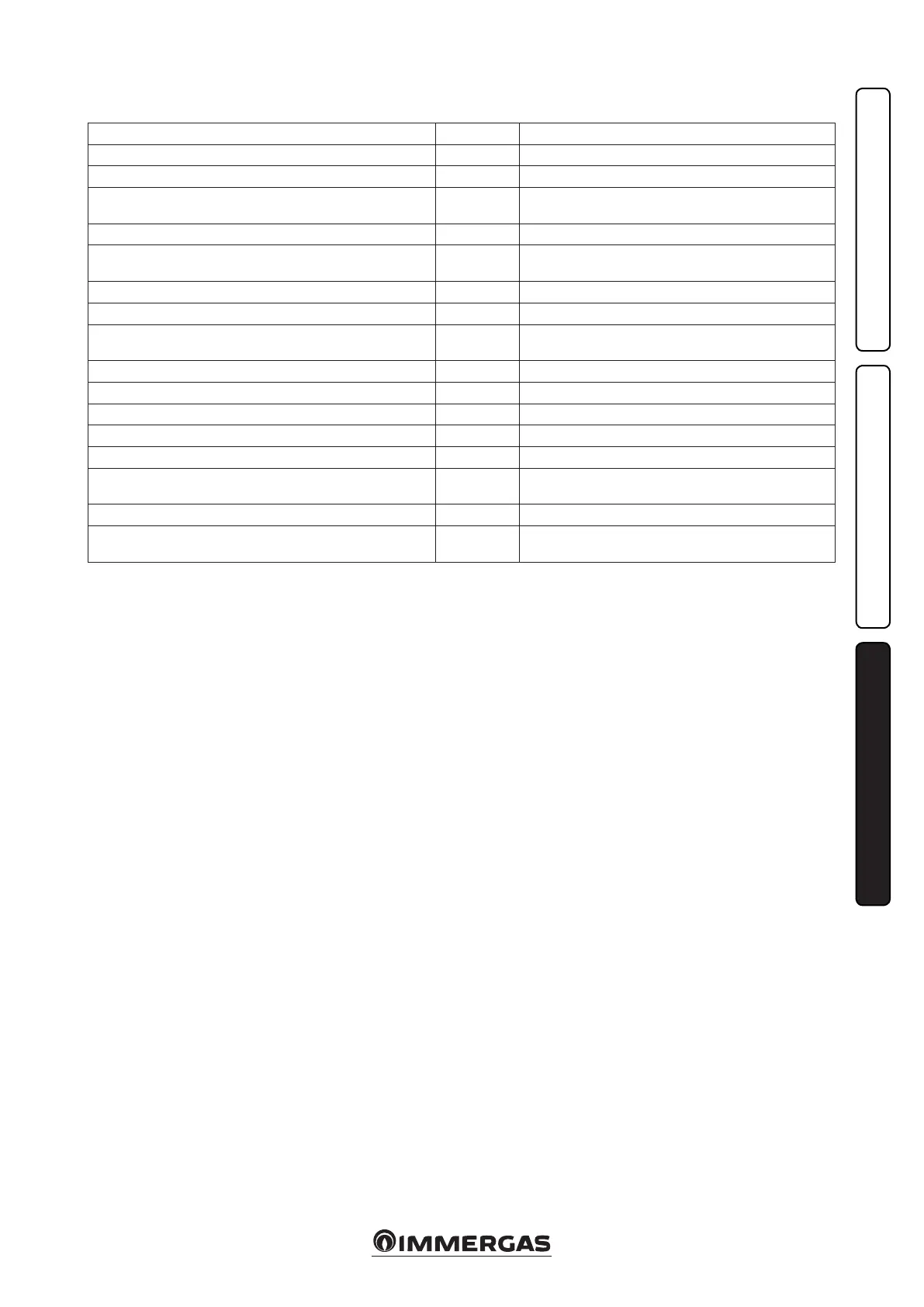

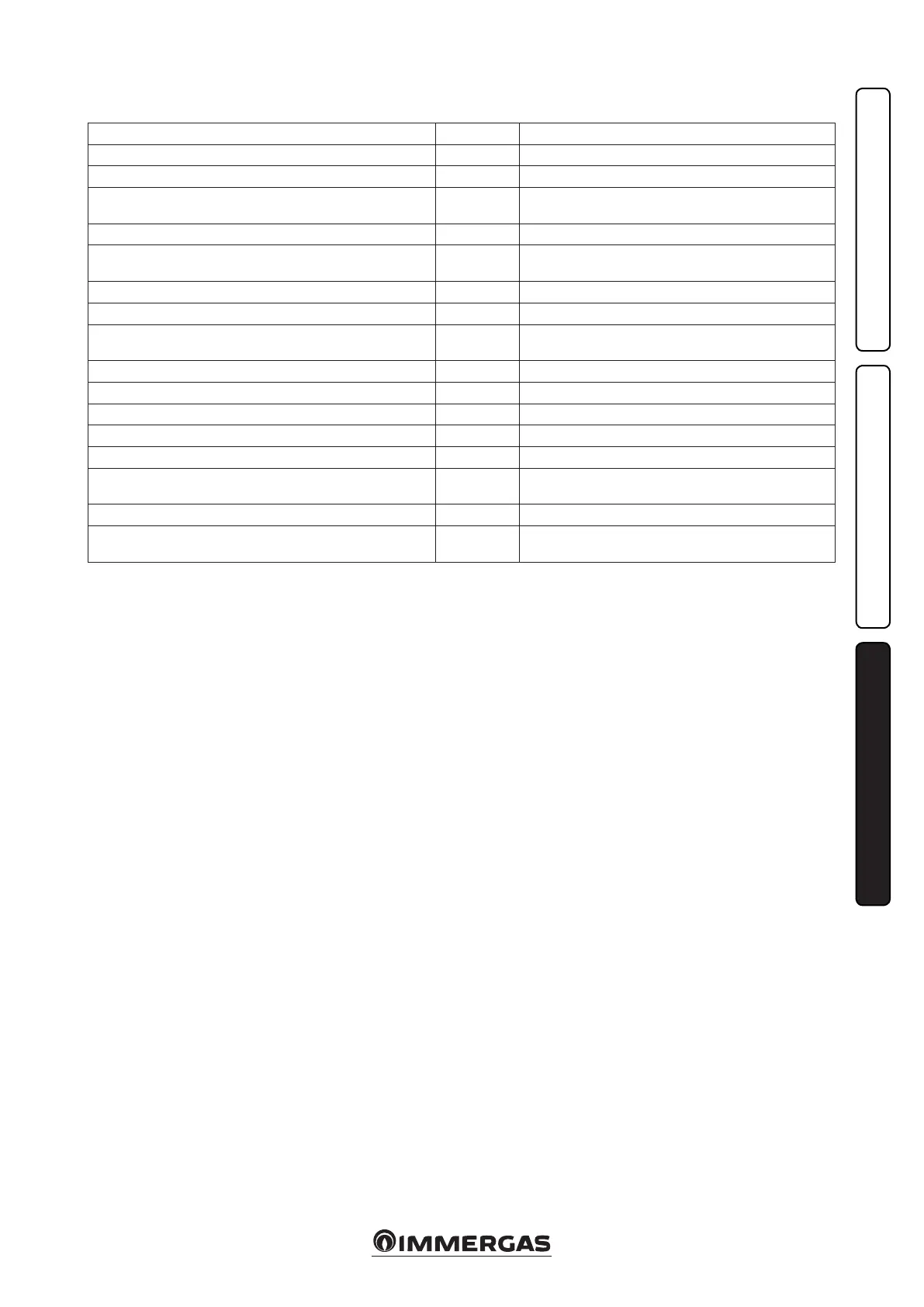

3.11 OBJECT OF PERIODIC

INSPECTION.

Unit Frequency Periodic inspection details

Electrical insulation measurement (Supply voltage circuit/compressor) Annually Electrical insulation measurement with "mega tester"

Operation control Annually Remote panel Central heating/Cooling control.

Coolant/water leakages inspection. Annually

Visual inspection and leakages control with a meter: No leak-

ages must be found.

Water heat exchanger inspection (internal dirt and clogging) Annually Check water dirt in a closed cycle. Clean.

Inlet/Outlet water temperature measurement Annually

Temperature measurement: Temperature measurement

during an operating cycle.

Pump circulation inspection Annually No leakages or anomalous noise must be found or heard.

Automatic air vent valve inspection Annually Water leakage, Air vent.

Expansion valve Annually

Visual control for pressure load anomalies, water leakages or

corrosion.

Flow switch Annually Check operations during operation

Safety valve Annually Water leakage, check the Aspect, check Draining.

Supply voltage measurement (no-load current/nominal operation) Annually Electrical voltage measurement: 230V ±23V

Supply voltage frequency Annually Frequency check: 50 Hz

Air heat exchanger inspection (Dirt or clogging) Annually Visual inspection, remove clogging

Fan inspection (Scratches, damage) Annually

Check any scratches or damage to the fan or anomalous nois-

es of the motor.

Cycle Parts (Compressor, 4-way valve, motor impulse valve) Annually Check operation with a test cycle

Inverter control panel, GMC panel, Terminal Board Annually

Check that there are no ttings or clamps that have come

loose

Loading...

Loading...