16

C

82

1-26

1-27

C

82

C

82

1-25

A S

1

8

10

11

5

7

3

2

S

A

4

8

9

6

INSTALLERUSERMAINTENANCE TECHNICIAN

• Temperature loss in ue ducts (Fig. 1-24). To

prevent problems of ue gas condensate in the

exhaust pipe Ø 80, due to fume cooling through

the wall, the length of the exhaust pipe must be

limited to just 5 metres. If longer distances must

be covered, use Ø 80 pipes with insulation (see

insulated separator kit Ø 80/80 chapter).

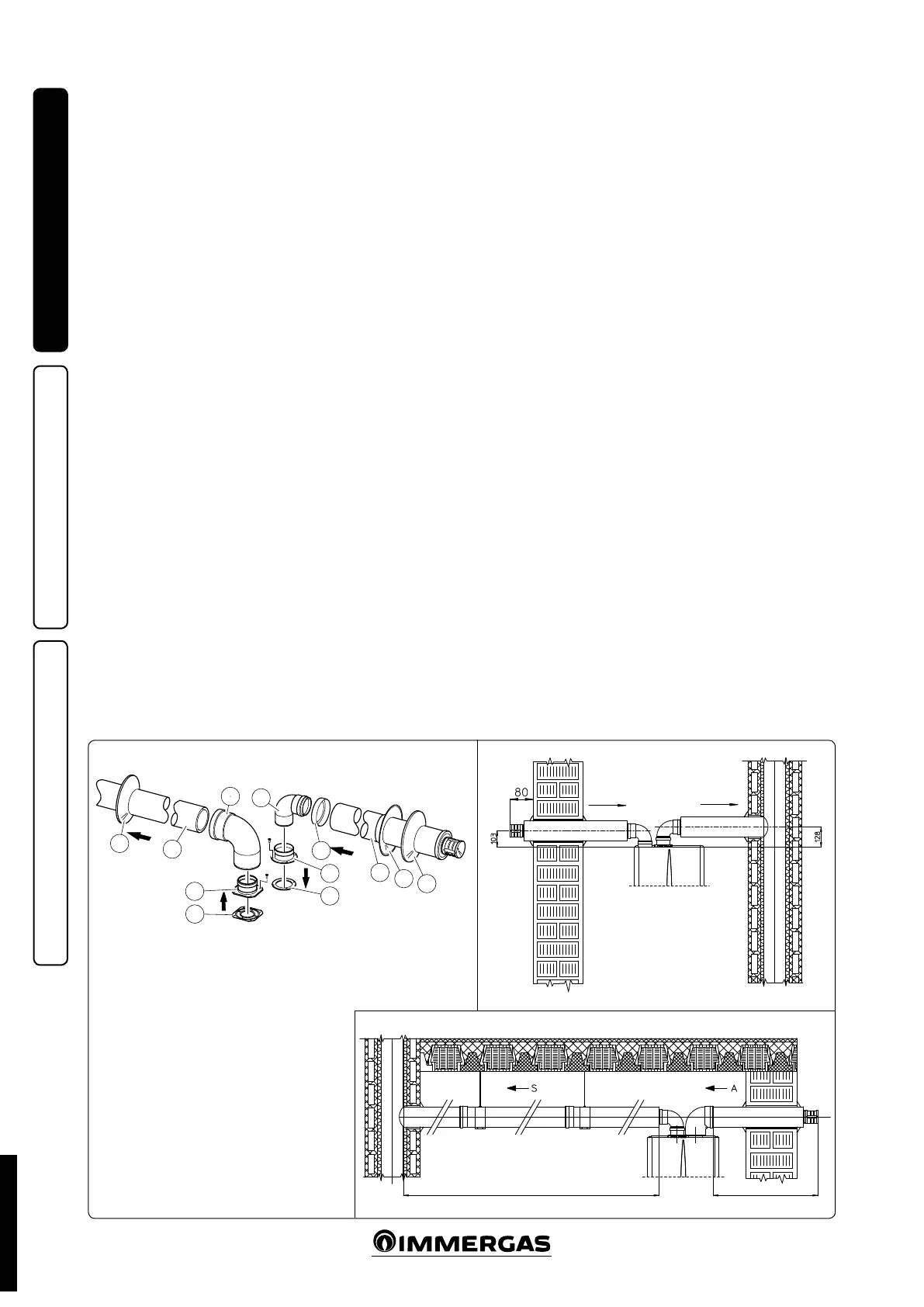

Insulated separator kit Ø 80/80. Kit assembly

(Fig. 1-25): install the ange (4) on the central

hole of the boiler, interposing the gasket (1) and

tighten with the at-tipped hex screws included

in the kit. Remove the at ange present in the

lateral hole with respect to the central one (ac-

cording to needs) and replace it with the ange

(3), positioning the gasket (2) already present in

the boiler and tighten using the supplied self-

threading screws. Insert and slide cap (6) onto

bend (5) from the male side (smooth), and join

bends (5) with the male side (smooth) in the

female side of ange (3). Fit bend (11) with the

male side (smooth) into the female side of ange

(4). Fit the male end (smooth) of the intake ter-

minal (7) up to the stop on the female end of the

bend (5), making sure you have already inserted

the wall sealing plates (8 and 9) that ensure cor-

rect installation between pipe and wall, then x

the closing cap (6) on the terminal (7). Join the

exhaust pipe (10) with the male side (smooth)

in the female side of the bend (11) to the end

stop, ensuring that the wall sealing plate (8) is

already inserted for correct installation between

the pipe and ue.

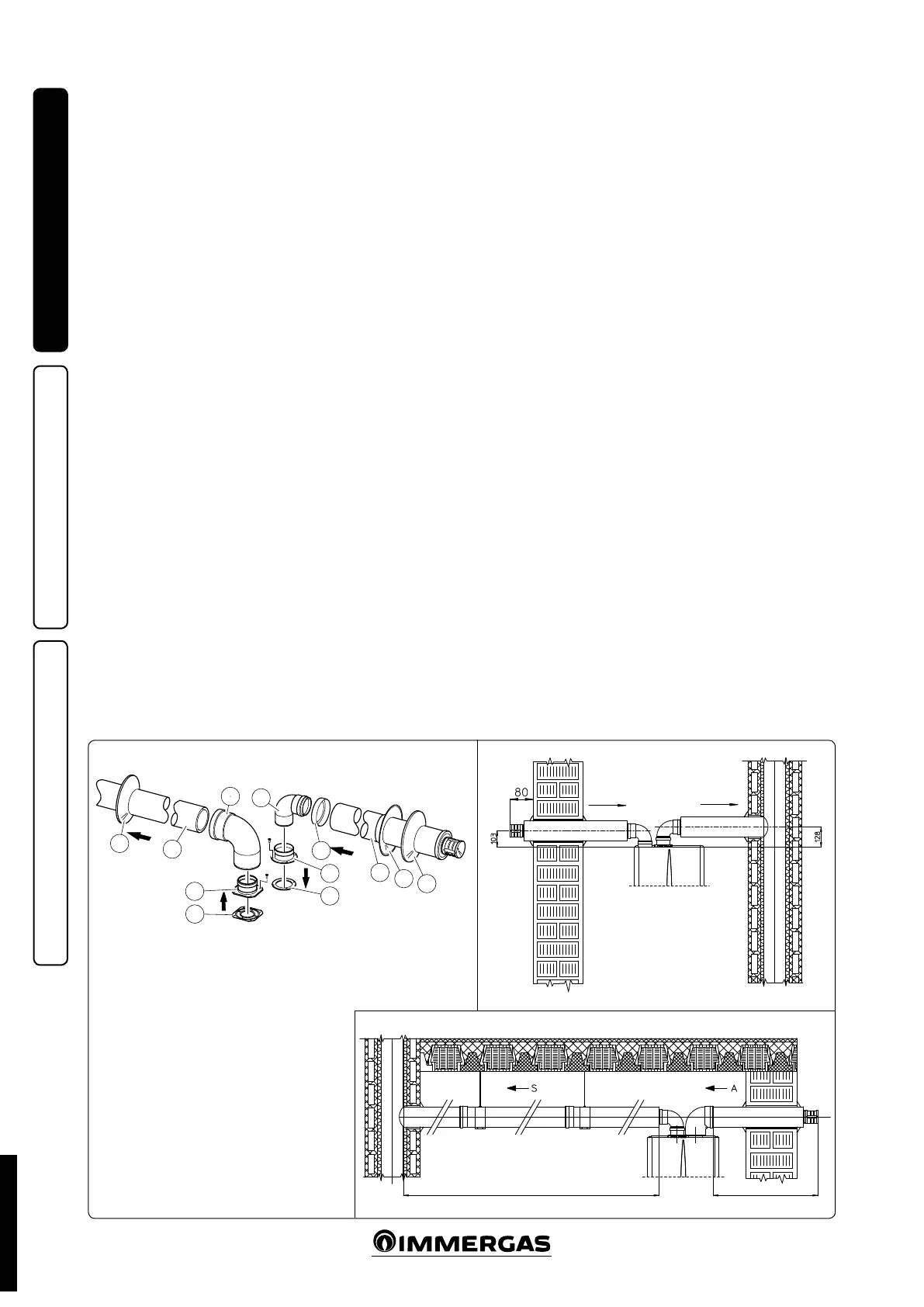

• Insulation of separator terminal kit. Whenever

there are ue gas condensate problems in the

exhaust pipes or on the external surface of the

intake pipes, on request Immergas supplies

insulated intake-exhaust pipes. Insulation

my be necessary on the exhaust pipe, due to

excessive loss of temperature of the ue gas on

their route. Insulation may be necessary on

the intake pipe as the air entering (if very cold)

may cause the outside of the pipe to fall below

the dew point of the environmental air. e

gures (Fig. 1-26 and 1-27) illustrate dierent

applications of insulated pipes.

Insulated pipes are formed of a Ø 80 internal

concentric pipe and a Ø 125 external pipe with

static air space. It is not technically possible to

start with both Ø 80 elbows insulated, as clear-

ances will not allow it. However starting with an

insulated elbow is possible by choosing either

the intake or exhaust pipe. When starting with

the insulated intake bend it must be engaged on

its ange until it is taken up to end stop on the

ue gas exhaust ange, a situation that takes the

two intake ue gas exhaust outlets to the same

height.

• Temperature loss in insulated ue ducting. To

prevent problems of ue gas condensate in the

insulated exhaust pipe Ø 80, due to ue gas

cooling through the wall, the length of the pipe

must be limited to 12 metres. e gure (Fig.

1-27) illustrates a typical insulation applica-

tion in which the intake pipe is short and the

exhaust pipe is very long (over 5 m). e entire

intake pipe is insulated to prevent moist air in

the place where the boiler is installed, in contact

with the pipe cooled by air entering from the

outside. e entire exhaust pipe, except the

elbow leaving the splitter is insulated to reduce

heat loss from the pipe, thus preventing the

formation of fume condensate.

N.B.: when installing the insulated pipes, a

section clamp with gusset must be installed

every 2 metres.

MAX 12 m

e kit includes:

N°1 - Exhaust gasket (1)

N°1 - Flange gasket (2)

N°1 - Female intake ange (3)

N°1 - Female exhaust ange (4)

N°1 - Bend 90° Ø 80 (5)

N°1 - Pipe closure cap (6)

N°1 - Intake terminal Ø 80 insulated (7)

N°2 - Internal rings (8)

N°1 - External wall sealing plate (9)

N°1 - Discharge pipe Ø 80 insulated (10)

N°1 - Concentric bend 90° Ø 80/125 (11)

MAX 21 m

STD.002998/004

Loading...

Loading...