15

C

82

C

42

C

52

1-24

C

82

1-21

1-22

1-23

1

4

7

9

5

5

6

7

8

3

2

S

A

INSTALLERUSERMAINTENANCE TECHNICIAN

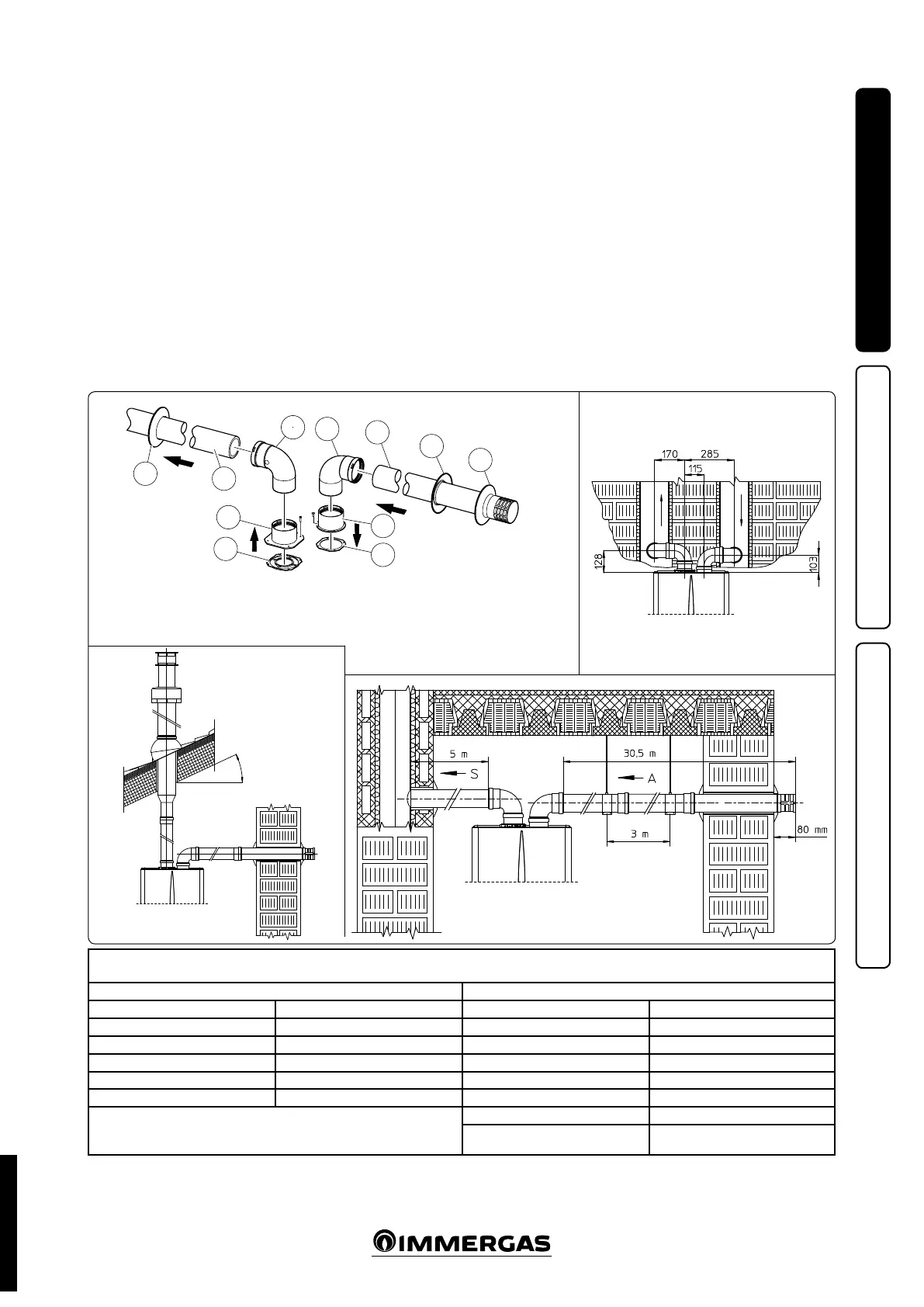

Maximum usable lengths

(including intake terminal with grill and two 90° bends)

NON-INSULATED PIPE INSULATED PIPE

Drain (metres) Intake (metres) Drain (metres) Intake (metres)

1 36.0* 6 29.5*

2 34.5* 7 28.0*

3 33.0* 8 26.5*

4 32.0* 9 25,5*

5 30.5* 10 24.0*

* e air intake pipe can be increased to 2.5 metres if the exhaust bend

is eliminated, 2 metres if the air intake bend is eliminated, 4.5 metres

eliminating both bends.

11 22.5*

12 21.5*

Attention: the boiler is designed to evacuate

the combustion products up to a maximum

extension of 27 linear metres from the exhaust,

with 1 m plus 90° bend at the intake. If the

installation requires a development of the ue

to the discharge that exceeds the recommended

12 m, due consideration must be given to the

formation of condensate that could take place

inside the pipe and insulated ue kits “NOT for

condensing boilers” must be used.

1.13 SEPARATOR KIT INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

This kit allows air to come in from outside

the building and the exhaust to exit from the

chimney, ue or intubated duct through divided

ue exhaust and air intake pipes. Combustion

products are expelled from pipe (S). Air is taken

in through pipe (A) for combustion. Both ducts

can be routed in any direction.

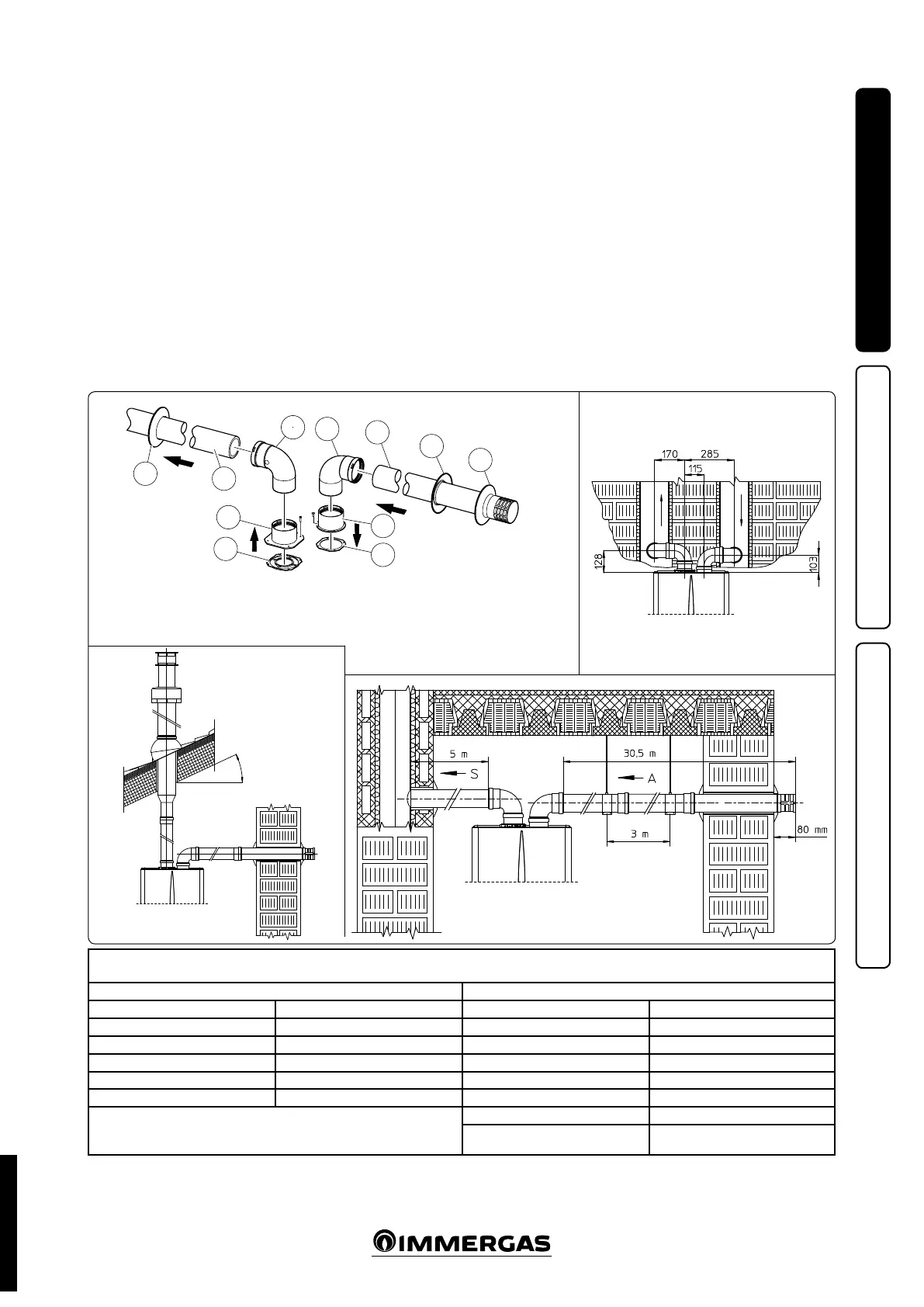

Separator kit Ø 80/80. Kit assembly (Fig. 1-21):

install the ange (4) on the central hole of the

boiler, interposing the gasket (1) and tighten

with the at-tipped hex screws included in the

kit. Remove the at ange present in the lateral

hole with respect to the central one (according to

needs) and replace it with the ange (3), position-

ing the gasket (2) already present in the boiler and

tighten using the supplied self-threading screws.

Fit the male end (smooth) to the bends (5) in the

female end of the anges (3 and 4). Fit the intake

terminal (6) with the male section (smooth) in

the female section of the bend (5) up to the end

stop, ensuring that the internal and external wall

sealing plates are tted. Fit the exhaust pipe (9)

with the male end (smooth) to the female end

of the bend (5) up to the stop; making sure that

the internal wall sealing plate has been tted, this

will ensure sealing and joining of the elements

making up the kit.

• Installation clearances (Fig. 1-22). e mini-

mum installation clearance measurements of

the Ø 80/80 separator terminal kit have been

stated in some limit conditions.

• Figure 1-23 shows the conguration with verti-

cal exhaust and horizontal intake.

• Extensions for separator kit Ø 80/80. e max.

vertical straight length (without bends) usable

for Ø 80 intake and exhaust pipes is 41 metres

of which 40 intake and 1 exhaust. is total

length corresponds to a resistance factor of

100. e total usable length obtained by sum-

ming the Ø 80 intake and exhaust pipe lengths

can reach, as a maximum, the values provided

in the following table. If mixed accessories or

components are used, the maximum extension

can be calculated by using a resistance factor

for each component or its equivalent length.

e sum of these resistance factors must not

exceed 100.

Max 45%

e kit includes:

N°1 - Exhaust gasket (1)

N°1 - Female intake ange (3)

N°1 - Flange gasket (2)

N°1 - Female exhaust ange (4)

N°2 - 90° bend Ø 80 (5)

N°1 - Intake terminal Ø 80 (6)

N°2 - Internal rings (7)

N°1 - External grey wall sealing plate (8)

N°1 - Exhaust pipe Ø 80 (9)

STD.002998/004

Loading...

Loading...