1-12

7 - IE

INSTALLATORUSERMAINTENANCE

1.7 INSTALLATION INDOORS.

• Type C conguration, sealed chamber and

forced draught.

Immergas supplies various solutions separately

from the boiler regarding the installation of air

intake terminals and ue extraction; fundamen-

tal for boiler operation.

Important: the boiler must only be installed

together with an origin Immergas air intake

and fume extraction system. is system can

be identied by a special distinctive marking

bearing the note: “not for condensing boilers”.

e fume exhaust pipes must not be in contact

with or near ammable materials and must not

cross building structures or walls made of am-

mable materials.

• Resistance factors and equivalent lengths.

Each flue extraction system component is

designed with a Resistance Factor based on

preliminary tests and specied in the table

below The resistance factor for individual

components does not depend either on the type

of boiler on which it is installed or the actual

dimensions. It is based on the temperature of

uids conveyed through the ducts and therefore

varies according to applications for air intake

or ue exhaust Each single component has a

resistance corresponding to a certain length

in metres of pipe of the same diameter; the

so-called equivalent length, obtained from the

ration between he relative Resistance Factors.

All boilers have an experimentally obtainable

maximum Resistance Factor equal to 100.

The maximum Resistance Factor allowed

corresponds to the resistance encountered with

the maximum allowed pipe length for each

type of Terminal Kit. is information enables

calculations to verify the possibility of various

congurations of ue extraction systems.

Positioning of double lip seals. For correct

positioning of lip seals on elbows and extensions,

follow the assembly direction given in the gure

(Fig. 1-7).

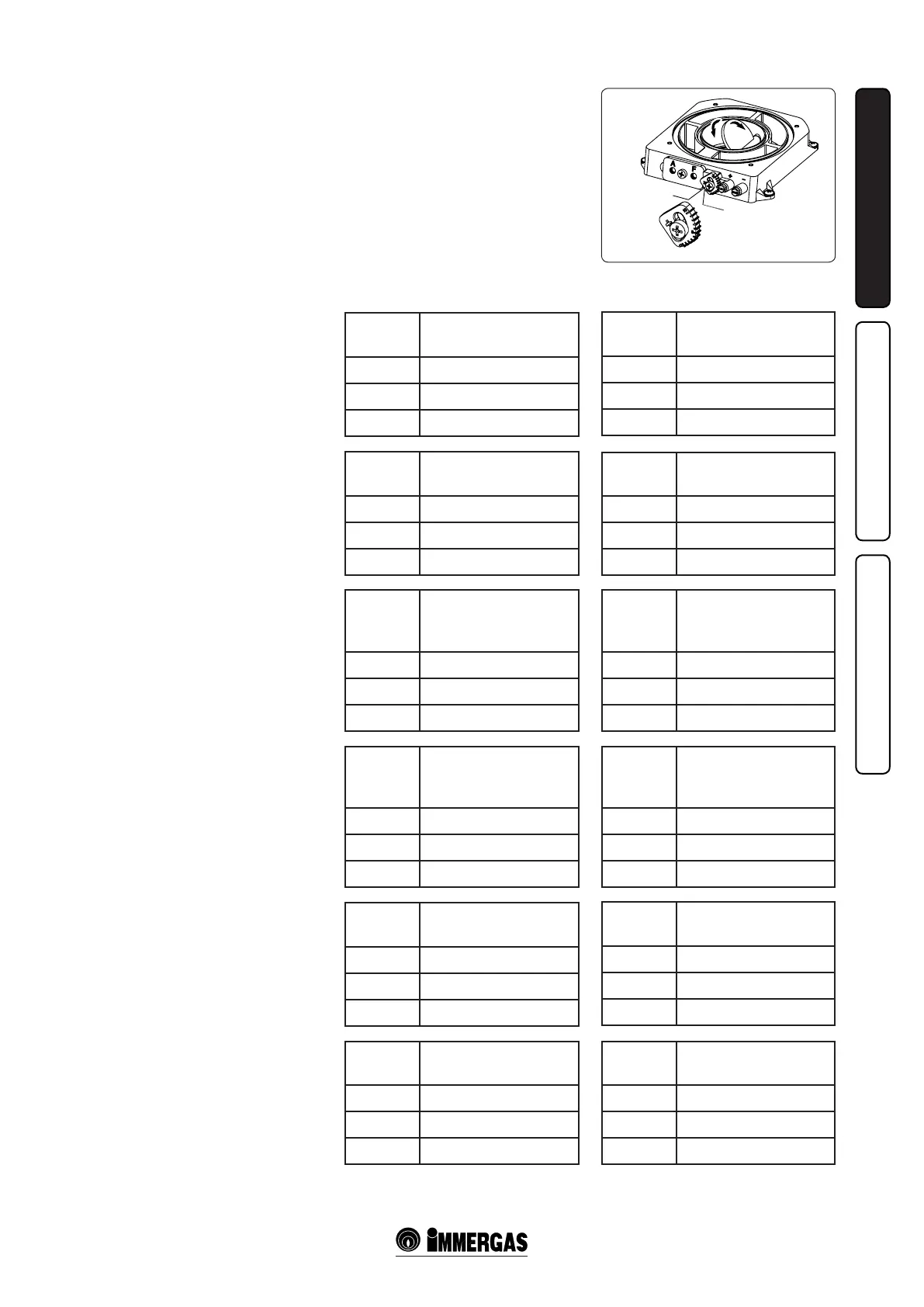

Fumes separator adjustment. For correct

functioning of the boiler the fumes separator

positioned on the air/fumes extraction well must

be adjusted (Fig. 1-12).

Adjustment is carried out by loosening the

front retainer screw and moving the indicator

to the correct position, aligning its value to the

horizontal reference (Fig. 1-12). Once adjustment

has been performed, tighten the screw to x the

separator. Appropriate adjustment takes place on

the basis of the type of pipe and its extension: this

calculation can be carried out using the fumes

separator adjustment tables.

Fumes

separator

*Duct length in metres

Ø 80 horizontal

With two bends

3 From 0 to 4

5 From 4 to 26

6 From 26 to 35

Fumes

separator

Duct length in metres

Ø 80/125 horizontal

3 From 0 to 0,5

5 From 0,5 to 4,6

10 From 4,6 to 7,4

Fumes

separator

Duct length in metres

Ø 80/125 vertical

3 From 0 to 5,4

5 From 5,4 to 9,5

10 From 9,5 to 12,2

Fumes

separator

*Duct length in metres

Ø 80 vertical

without bends

3 Da 0 to 8

5 Da 8 to 30

6 Da 30 to 40

* e values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

Fumes

separator

Duct length in metres

Ø 60/100 horizontal

3 From 0 to 0,5

5 From 0,5 to 2

10 From 2 to 3

Fumes

separator

Duct length in metres

Ø 60/100 vertical

3 From 0 to 2,2

5 From 2,2 to 3,7

10 From 3,7 to 4,7

Fumes separator adjustments

Zeus 24 kW.

Fumes separator adjustments

Zeus 28 kW.

Fumes

separator

*Duct length in metres

Ø 80 horizontal

with two bends

3 From 0 to 2

5 From 2 to 21

7 From 21 to 35

Fumes

separator

Duct length in metres

Ø 80/125 horizontal

3 From 0 to 0,5

5 From 0,5 to 4,6

10 From 4,6 to 10,1

Fumes

separator

Duct length in metres

Ø 80/125 vertical

3 From 0 to 5,4

5 From 5,4 to 9,5

10 From 9,5 to 15,0

Fumes

separator

*Duct length in metres

Ø 80 vertical

without bends

3 From 0 to 6

5 From 6 to 25

7 From 25 to 40

Fumes

separator

Duct length in metres

Ø 60/100 horizontal

3 From 0 to 0,5

5 From 0,5 to 2

10 From 2 to 3

Fumes

separator

Duct length in metres

Ø 60/100 vertical

3 From 0 to 2,2

5 From 2,2 to 3,7

10 From 3,7 to 5,7

* e values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

Loading...

Loading...