5.2 Electrical mains connections

GHN (basic, auto), GHND (basic, auto) pumps are provided with built-in, three

phase electric motor, to be connected with A.C. mains of 3~400 V, 50Hz.

GHNM (basic, auto), GHNMD (basic, auto) type pumps have built-in, single

phaseelectricmotor1x230V,50Hz.

The motor is internally protected with bimetal switch. The electric motor

haveabuilt-in,thermalcutout,thatwillswitchofftheelectricmotorwhenitis

overheated.

The fuse forisolation ofall polesfrom the mains should be incorporated in

accordance with the national electrical installation standards.

ThemotorprotectionswitchIskraMISMS25,SchrackALEAorsimilarswitches

areappropriatefuses.

The connecting wire has to be connected over a cable entry M20 (Fig.2 –

POS.7).

- Allwaterconnectionsmustbeinstalledatalevelatwhichthepipelineand/orhydraulic

casingofthepumpand/ormotorcasingarenotooded.

- Check that the mains voltage agree with the particulars stamped on the rating plate.

- Fuseonthesideofmains:pleaserefertotheratingplate.

- Thepump/systemmustbeearthed(grounded)inaccordancewiththeappropriate

standards.

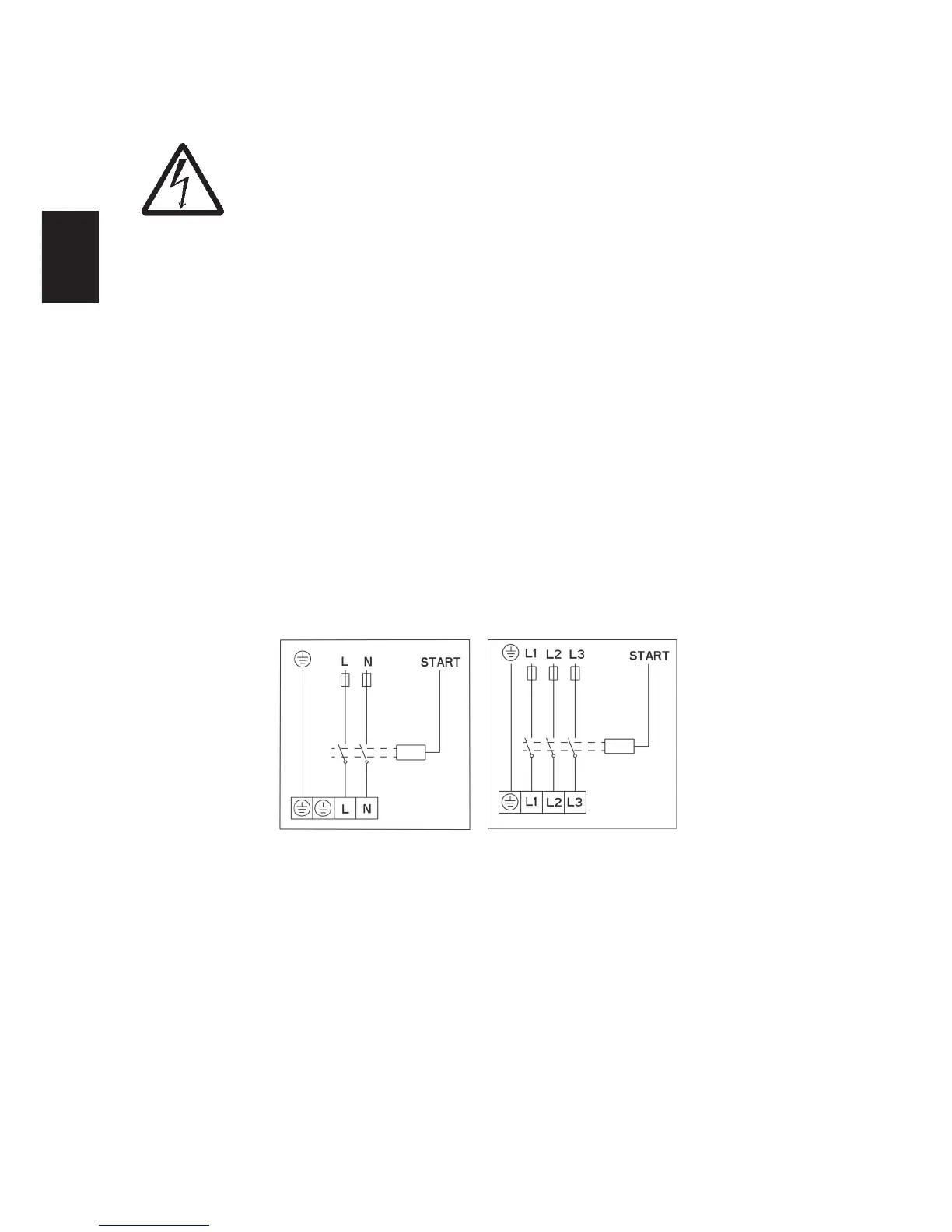

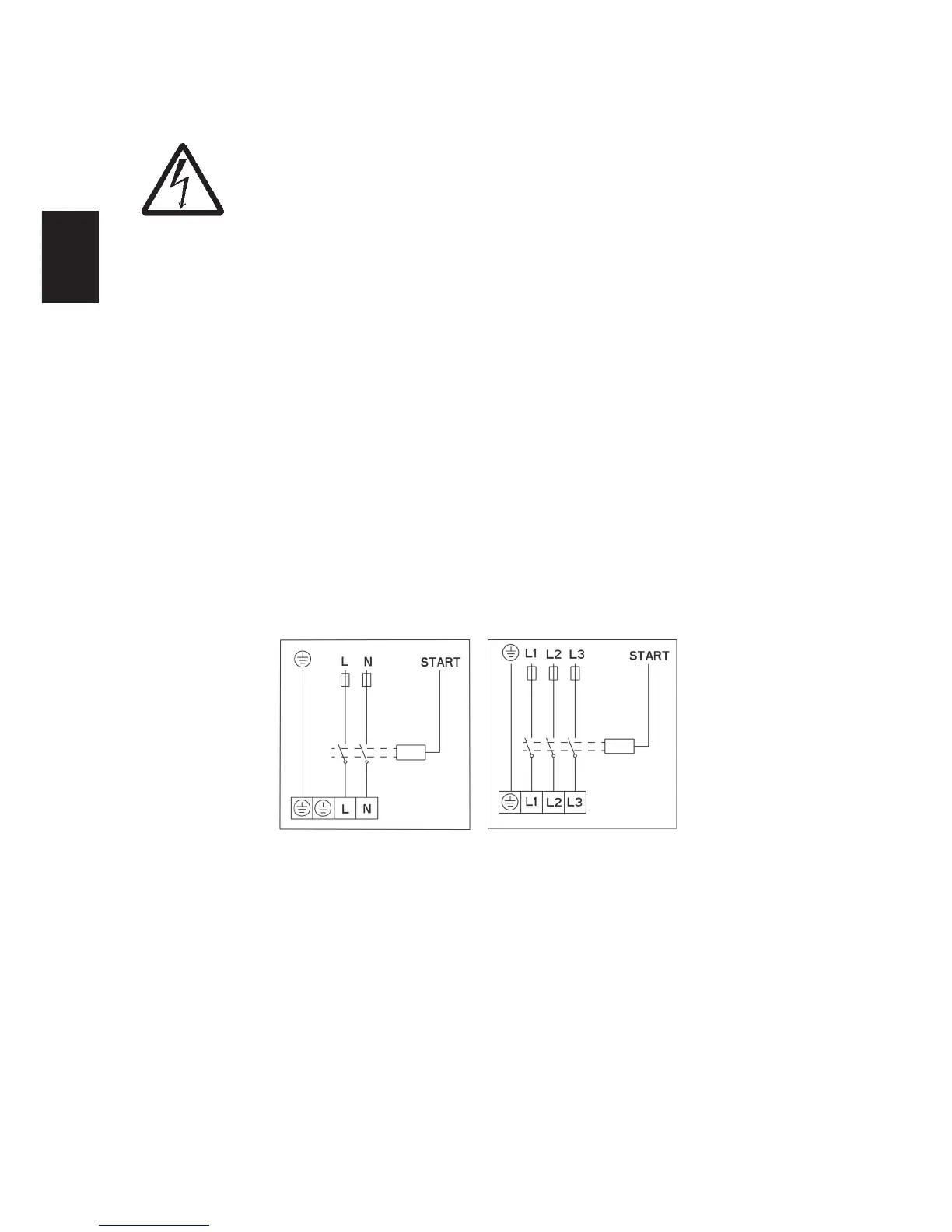

5.2.1 Electrical connection of pumps

Electrical connections of the pump must be carried out in accordance with the wiring

diagram(Fig.4),attachedonthebottomofmotorcover.Beforedoingthatunwindthe

uppercover(Fig.2-POS.2).

Fig.4

6.1 Loading and deaeration

In the pumps of types GHN (basic auto), GHND (basic, auto), GHNMD (basic, auto),

GHNMD (basic, auto) the rotor is submerged and provided with special water-lubricated

bearings. Before putting the pump into operation, it has to be lled with water and

deaerated.Deaeratethepumpbyunscrewingascrewonthebacksideoftheelectric

motor(Fig.2-POS.5).Airwillowoutthroughthecleftbetweenthemotorshaftandthe

bearing.Whenwaterstartstoowout,closethevalvesatboththesuctionandpressure

sideofthepump.Startthepumpandcheckthedirectionofshaftrotation.Incaseofa

wrongdirectionabuilt-inashlampwillstarttoblinkwithredlight.

Thepumpisalsoprovidedwithotherdetectorsforidentifyingerrors,listedinthetablebelow.

Loading...

Loading...