6-14

Indmar Marine Engines

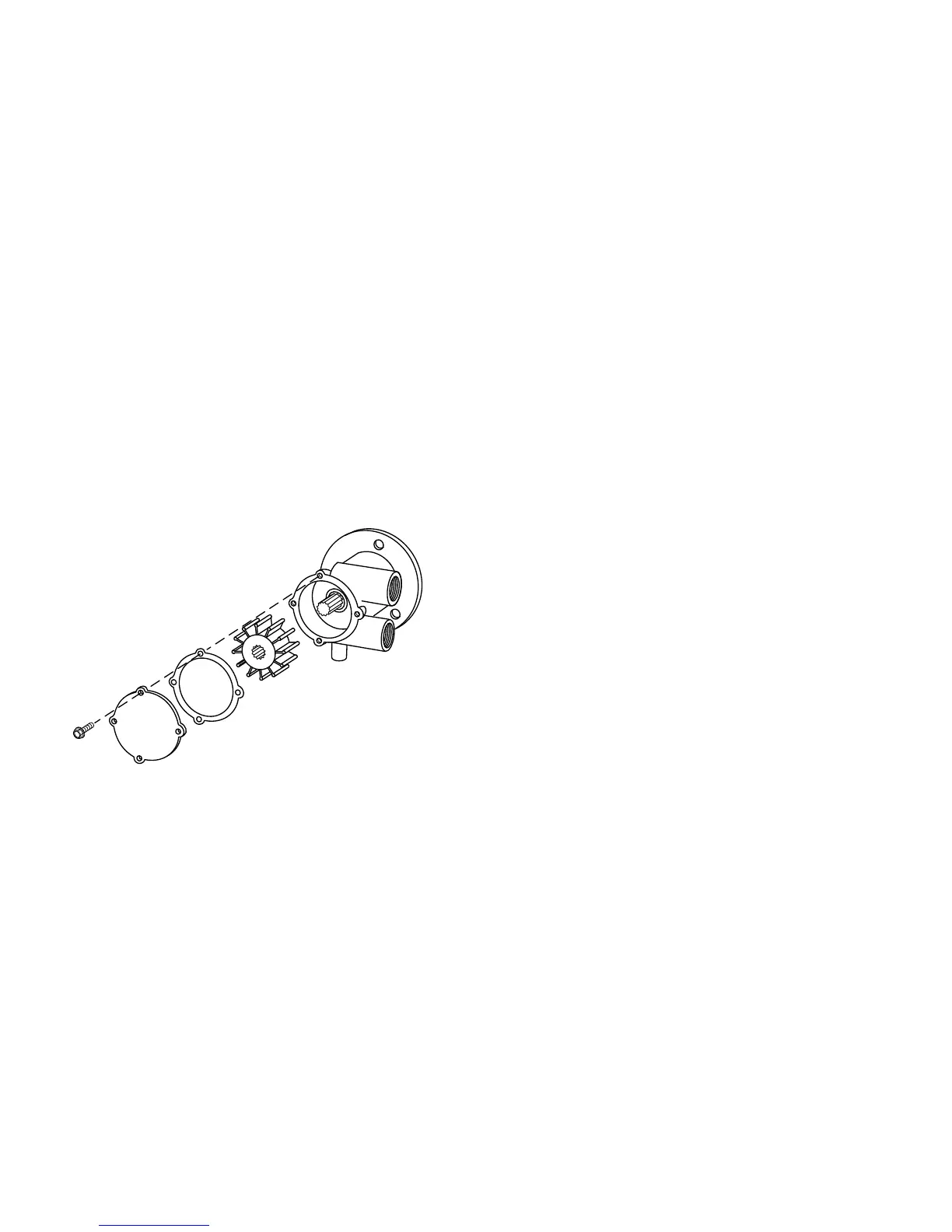

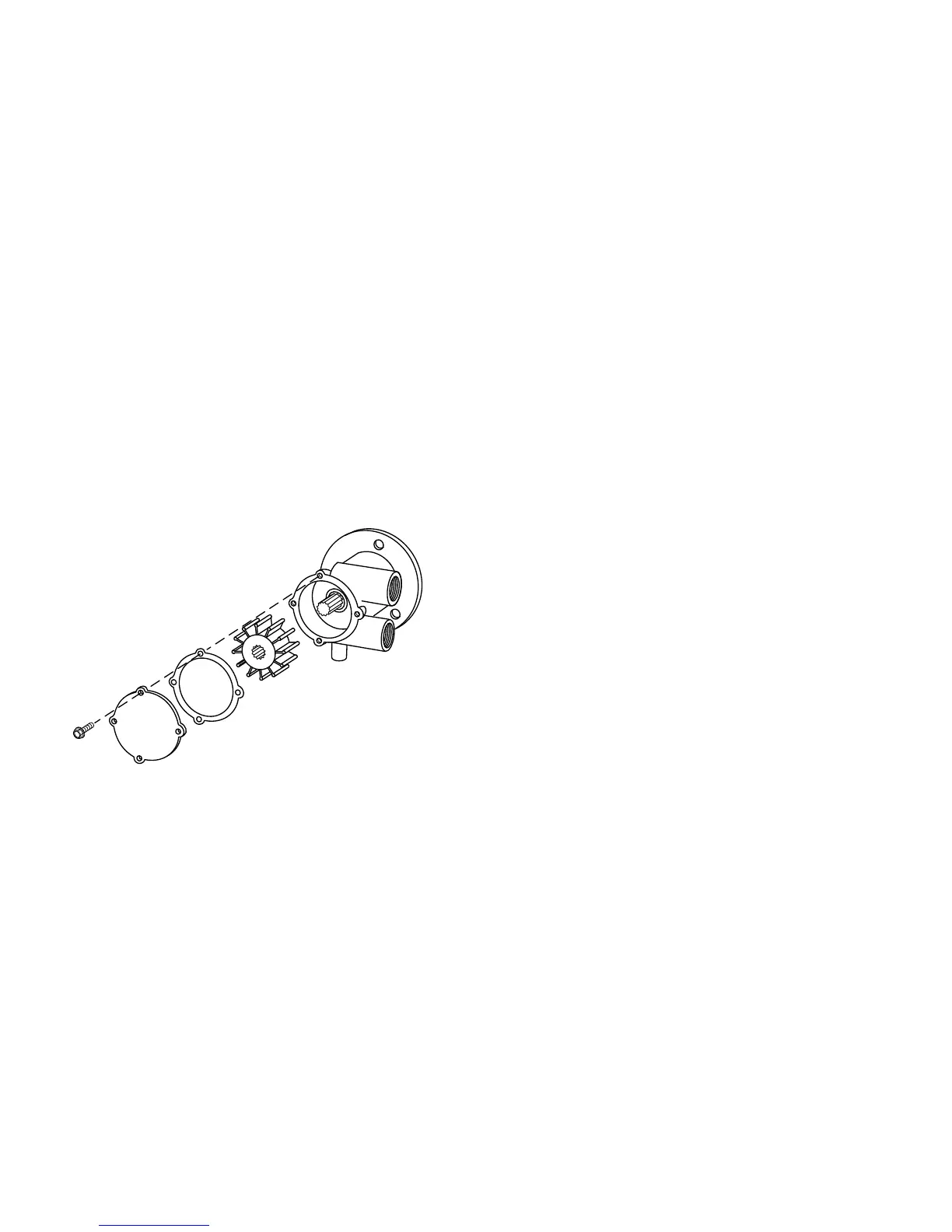

Raw Water Pump – Replace the impeller if it is worn or

over one year old. Since you must remove the impeller

to inspect it, it is good practice to replace the impeller

every year as a routine. Be sure there are no impeller

parts lodged in the hoses or elsewhere in the system as

they will eventually move to an inconvenient place and

restrict water flow. The raw water pump impeller should

be replaced every year or whenever it is found

to be worn or have damaged blades. Be sure to

re-assemble with the proper gaskets.

Figure 6.8 – Raw Water Pump Impeller

FUEL SYSTEM

The fuel system consists of fuel lines, fuel pump, and an

unused fuel recovery system. Fuel in the system is

under pressure and must be relieved before servicing.

Because of the inherent danger of fuel leakage into the

bilge, do not attempt servicing or maintaining compo-

nents of the fuel system.

Your Indmar dealer has factory trained technicians and

U.S. Coast Guard approved marine grade parts required

for fuel systems.

TRANSMISSIONS

NOTICE

It is important to keep the water level in the bilge below

the output shaft of the transmission. If the water level in

the bilge is too high, the coupler can splash water

inside the engine compartment and cause corrosion

problems. High water levels can also allow water intru-

sion into the transmission causing severe damage.

Indmar engines are equipped with one of these marine

transmissions:

• ZF Hurth Marine In-Line

• ZF Hurth Ski-Vee

• Walters V-Drive and ZF Hurth In-Line

• Indmar-Vee

Loading...

Loading...