22607402 Rev.D EN-9

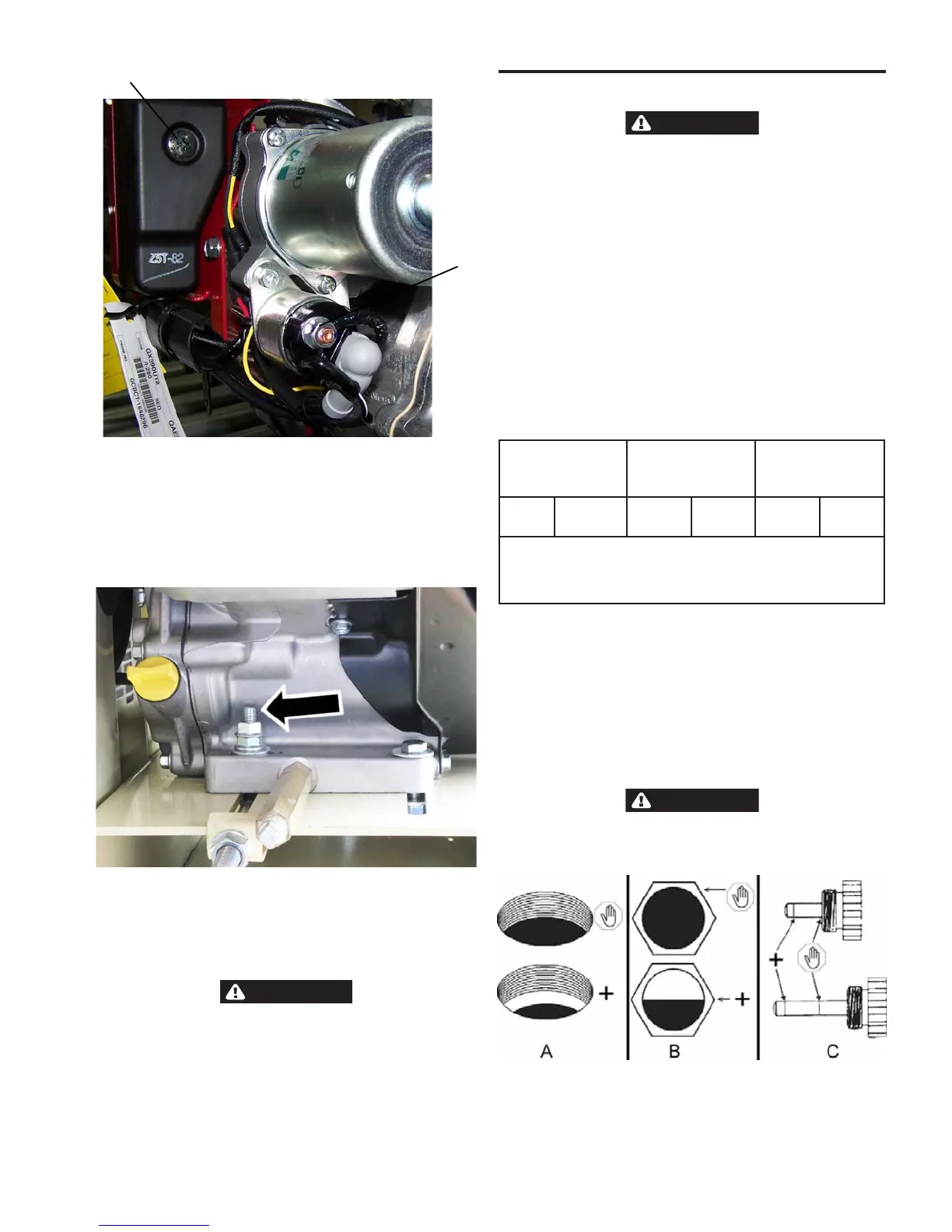

Honda Engine Battery (+) Positive cable connection point.

NOTE: Circuit Fuse location at (D). Electric Start will not work if Fuse

is blown. Unit can be rope started, however will not charge battery

if Fuse is blown

2) Connect the battery negative (-) cable (C) to the bolt shown in

the following illustration. Secure the wire in place by screwing a

suitably-sized nut onto the bolt and down onto the terminal.

3) Connect the battery positive (+) cable (A) to the battery positive

(+) terminal.

4) Connect the battery negative (-) cable (C) to the battery negative

(-) terminal.

5) Coat the terminals and cable ends with corrosion-preventive

grease.

Remove the cable from the negative (-) side of the battery

before servicing.

Refer to the engine manufacturer’s instructions for more information.

COMPRESSOR LUBRICATION

Do not operate without lubricant or with inadequate lubricant.

Ingersoll Rand is not responsible for compressor failure caused

by inadequate lubrication.

RECOMMENDED LUBRICANT

Ingersoll Rand recommends All Season Select® synthetic lubricant

from startup.

ALTERNATE LUBRICANTS.

You may use XL-300 or a comparable petroleum-based lubricant that

is premium quality, does not contain detergents, contains only anti-

rust, anti-oxidation, and anti-foam agents as additives, has a ashpoint

of 440°F (227°C) or higher, and has an auto-ignition point of 650°F

(343°C) or higher

See the petroleum lubricant viscosity table below. The table is

intended as a general guide only. Heavy duty operating conditions

require heavier viscosities. Refer specic operating conditions to

Ingersoll Rand for recommendations.

TEMPERATURE

AROUND

COMPRESSOR

VISCOSITY

100°F 37.8°C

VISCOSITY

GRADE

°F °C SUS CENTI

STOKES

ISO SAE

< 40 < 4.4 150 32 32 10

40-80 4.4-26.7 500 110 100 30

80-125 26.7-51.0 750 165 150 40

If you use a petroleum-based compressor lubricant at start-up and

decide to convert to All Season Select later on, the pump must be

decarbonized and ushed before conversion. Contact Ingersoll Rand

for more information

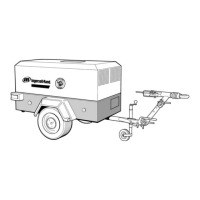

FILLING PROCEDURES

Unscrew and remove the oil ll plug.

Fill the crankcase with lubricant.

Replace the oil ll plug HAND TIGHT ONLY.

Do not remove the oil ll plug while the compressor is running.

Use one of the following methods illustrated to determine when the

crankcase is full.

A = Oil ll opening, B = Sight glass, C = Dipstick

Refer to the following table for crankcase capacity.

1)

2)

3)