Appendix: Disassembly of Flat Key and Oil Sealing

- 54 -

Appendix: Disassembly of Flat Key and Oil Sealing

■

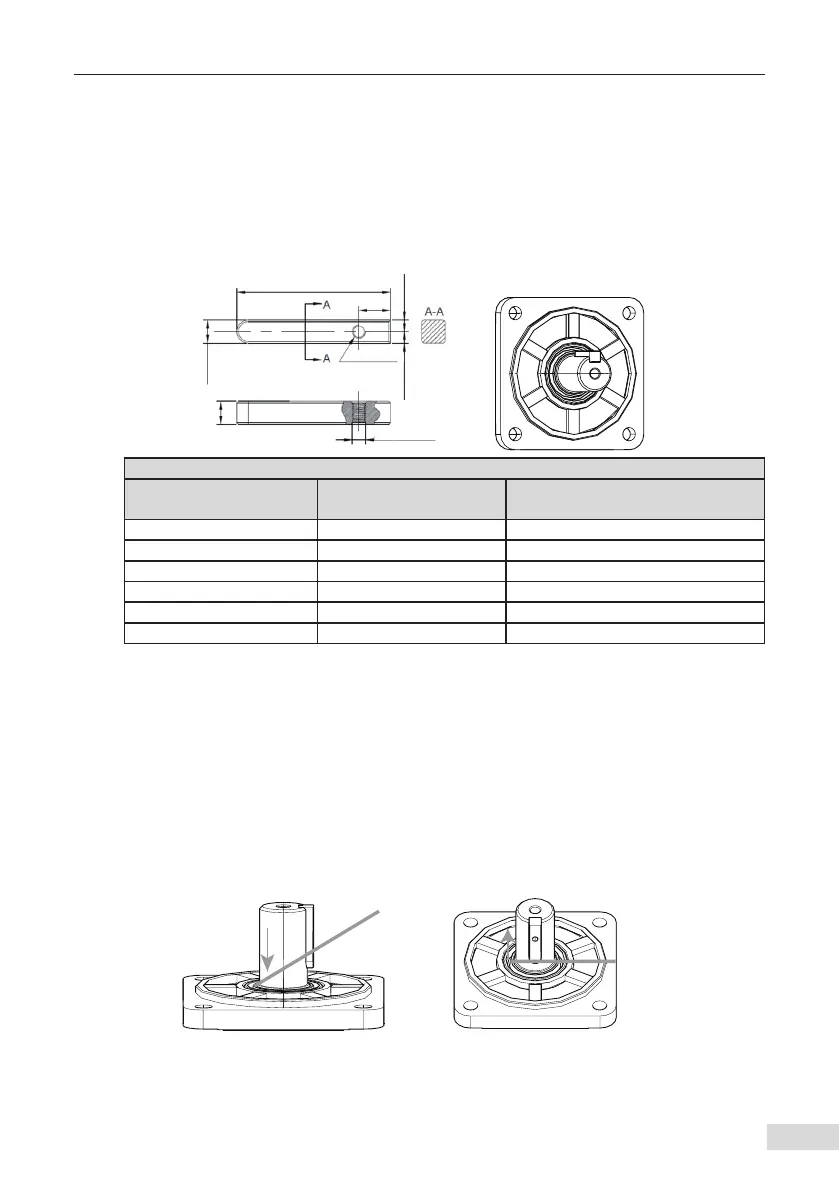

Removal of the motor at key

Standard MS1 series motors in frame sizes 60, 80, and 130 adopt C-type at keys. All the

at keys carry holes for easy key removal. To take the at key out, select a proper bolt

(inner hexagon bolt recommended) and an Allen wrench to screw down the bolt until

the A-A end of the at key is completely detached from the keyway, as shown below.

Key removal hole

M3 bolt for key removal

Specications of bolts for key removal

MS1 Motor Specications Dimensions of Flat Keys

Specications of Bolts (Inner

Hexagon Bolts) for Key Removal

Frame size 40 A-type at key - A3x3x14 No key removal hole

Frame size 60 C-type at key - C5x5x16.5 Length above M3X10

Frame size 80 C-type at key - C6x6x25 Length above M3X15

Frame size 100 C-type at key - C8x7x35 Length above M3X20

Frame size 130 C-type at key - C8x7x35 Length above M3X20

Frame size 180 C-type at key - C10x8x64 Length above M3X20

■

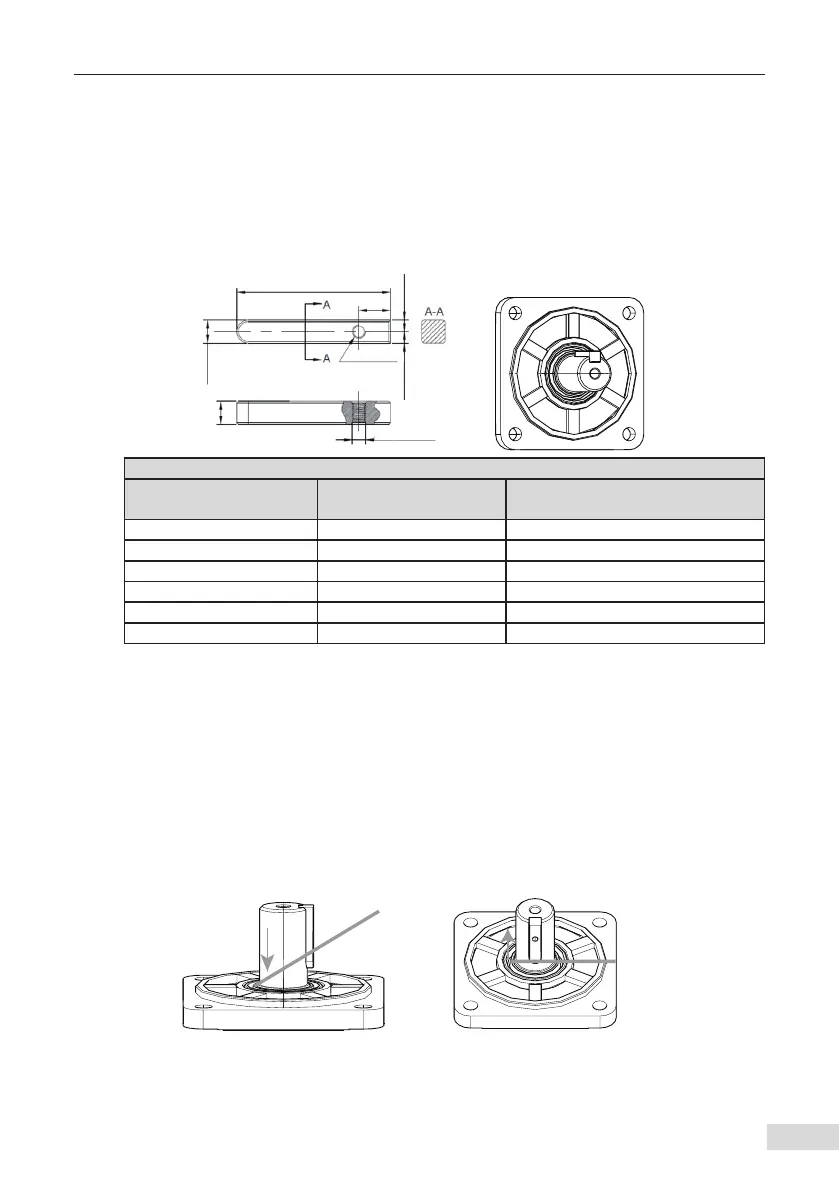

Removal of motor oil sealing

Tools needed: a needle-nose plier, a pair of slip-proof gloves, and a piece of cotton cloth

Operating steps:

1) Put the cotton cloth on the support point B to avoid end cover scratches during

removal.

2) Secure the motor and use the needle-nose plier to hold point A of the oil sealing

lip.

3) Pry the oil sealing out Frame Sized on the support point B.

#

(Point B acts on the shaft extension stairs)

"

(Point A acts on the oil sealing lip)

Loading...

Loading...