An imminently hazardous situation, which, if not avoided, will result in death or serious injury.

A potentially hazardous situation, which, if not avoided, could result in death or serious injury.

A potentially hazardous situation, which, if not avoided, may result in minor or moderate injury.

B

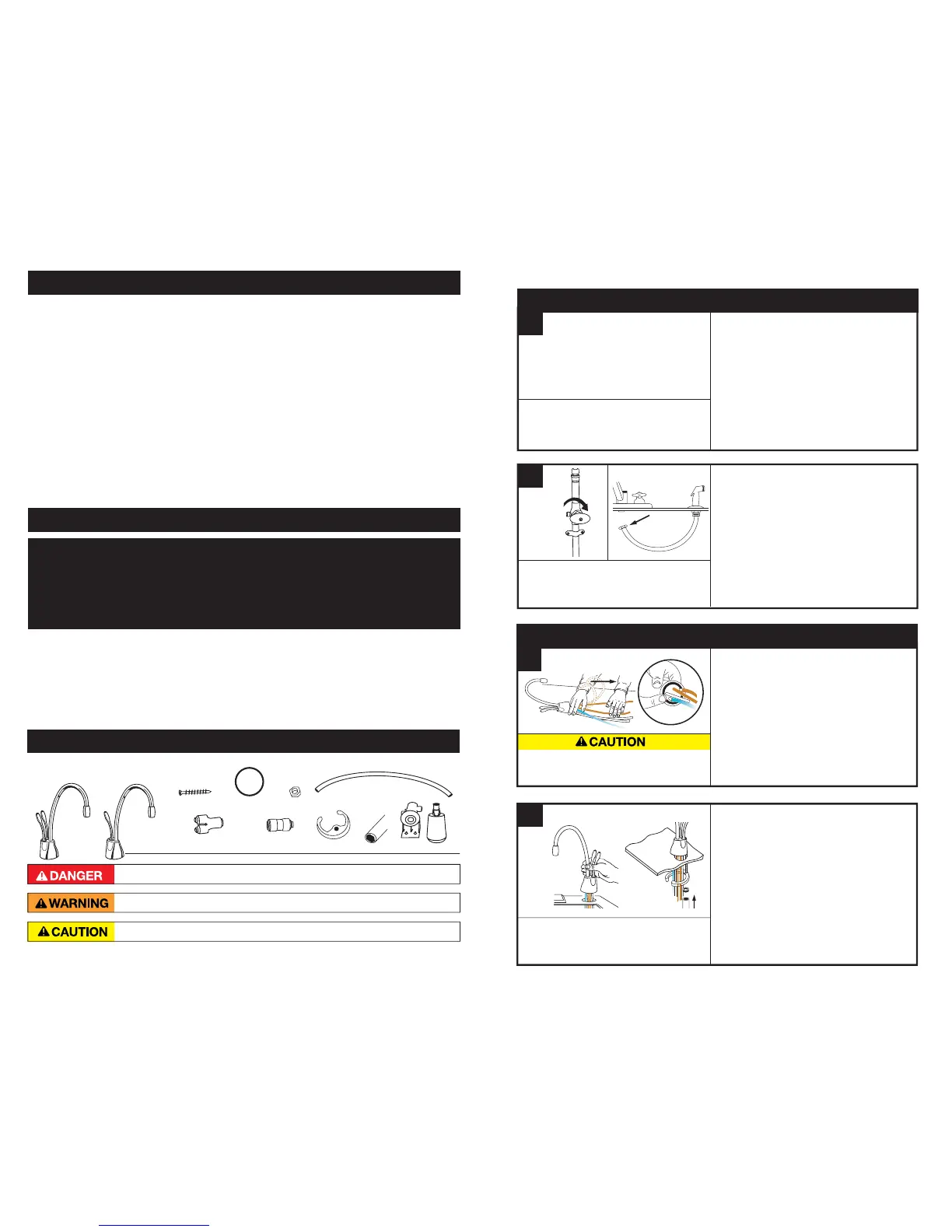

IN THIS PACKAGE

(# '.

NN8IJUF5VCFT

NN4DSFXT

3VCCFS03JOH

i:u2VJDL$POOFDUPS

'JMUFS4ZTUFN

4FNJDJSDVMBS

.PVOUJOH1MBUF

)FY5PPM

2VJDL$POOFDUPST

)FY/VU

GPS)$0OMZ 4VQQMJFE

■ For your satisfaction and safety, read all instructions, cautions, warnings and dangers before installing

or using this steaming hot water tap.

■ This particular unit is not intended for commercial use.

■ Make sure that all electrical wiring and connections conform to local codes.

■ A standard, earth (grounded) electrical outlet is required under the sink for the tap’s electrical power.

■ The wall outlet powering your tap must have electrical power supplied to it continuously.

■ This outlet must be fused and should not be controlled by the same wall switch that operates the

food waste disposer. Fuse/circuit breaker required is 10 amp for 230 volt and 15 amp for 120 volt.

■ To ensure proper operation, this unit is not intended to be flushed with chlorine. If you suspect elevated

levels of chlorine in your water, it is recommended to use our water filtration system.

■ To prevent damage or unit not operating properly, the water pressure must be between 172 kPa - 862 kPa

(1.7 bar - 8.6 bar; 25 psi - 125 psi). Ambient (room) temperature between 1ºC and 38ºC.

■ Moving parts inside the tank causing a rattling noise is normal.

■ If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

WHAT YOU SHOULD KNOW BEFORE YOU BEGIN

■ Phillips and flat blade screwdrivers

■ Pencil

■ Tape Measure

■ Level

Equipment You May Need:

Equipment Required:

■ Drill

■ Compression fitting,

T-fitting or saddle valve

■ Adjustable wrench

■ Hole punch

If you intend to use the sprayer hole in the sink for the hot water tap, you may need a 3.18mm plug or a

6.35mm cap (not supplied) for the sink spray hose line. See Step 1-B. If you need to cut a mounting hole in the

stainless steel sink, you may need a hole punch or a 35mm - 38mm hole saw made for cutting stainless steel.

WHAT YOU NEED TO GET STARTED

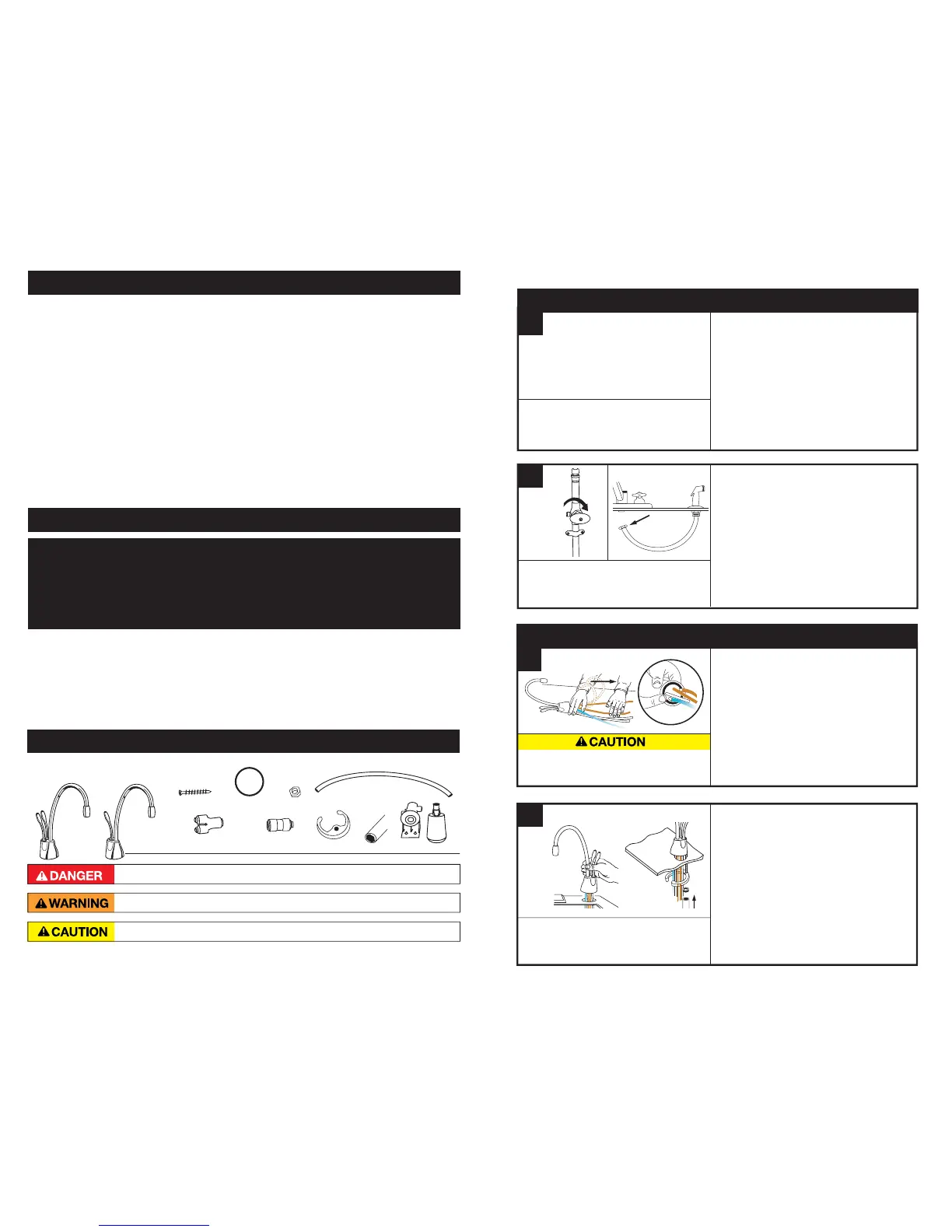

Property Damage: Do not pinch or break copper

tubing. Do not distort the last 25mm of tubing.

■ Feed tubes down through the hole

in the sink or countertop until the

base is at rest.

■ From under the sink, place the

semi-circular mounting plate and hex

nut onto the threaded stud. Ensure

tap head is at desired angle.

■ Insert screwdriver into hole on side of

hex tool (creating a “T”), and use tool

to tighten nut and secure tap.

■

Unpack hot water tap components.

■

On a firm, flat surface, carefully

straighten the copper tubing.

■ Ensure that the black O-ring is

properly seated in the base of

the tap head (the groove on the

underside of the tap).

B

An assistant may be needed to hold the tap

in place while securing.

2

A

INSTALLING THE TAP

PREPARATION

START HERE

PROPER INSTALLATION SHOULD TAKE ABOUT 2-4 HOURS

■ Identify locations for the tap, tank

and filter (if applicable).

■ Check to make sure there is proper

clearance (see chart at left) for tap

handles to be fully opened.

■ Check to make sure counter is not

too thick (see chart at left).

■ Make sure there is an earth (grounded)

electrical outlet under the sink.

■ If using the sink sprayer hose hole,

remove nut that connects sprayer

hose at bottom of tap.

■ Using adjustable wrench, remove nut

connecting sprayer washer flange in

sprayer hole.

■ Close hose opening with either a

plug or a cap (not supplied).

1

The wall outlet for the tap must have power

supplied to it continuously and must be fused.

It should not be controlled by the same wall

switch that operates the food waste disposer.

HC1100 ...... 100mm ...............76mm

GN1100 ...... 110mm ...............76mm

If you have to drill through sink or

countertop, you may need to rent or

purchase the appropriate tools.

Required minimum from

center of hole to wall

Maximum counter

thickness (depth)

2

A

■ Phillips and flat blade screwdrivers

■ Pencil

■ Tape Measure

■ Level

Loading...

Loading...