Installation

The boiler must be installed on a horizontal work

surface with sucient strength to support its

weight.

Locate in an area where there is adequate space

to use the boiler safely (e.g. free from risk of

congestion and tripping hazards).

Connection to Mains Water Supply:

Connect the WRAS approved water lling hose

(3/4”BSP) to the inlet connection point on the

back of the boiler and the other end to the mains

water supply, via an accessible isolating tap with

a ¾”BSP thread.

IMPORTANT: If micro-bore pipe is used

instead of the inlet hose supplied, the size

must be minimum OD 3/8”(10mm).

The water supply must have a pressure not

exceeding 7bar (96psi), and no lower than 2bar

(28psi) NOTE: If your water pressure exceeds

7bar, t a suitable pressure reduction valve.

We regret that Instanta cannot be held

responsible for any machine malfunctions if

the water pressure exceeds that stated. If in

doubt, consult your water supply company

Electrical Connection:

The boiler must be Earthed.

All 3.0KW models:Your machine is supplied

with a standard 13amp bonded plug with a

13amp fuse.

All 6.0KW models:

Your machine is supplied with a 1.5mtr cord

(3-core @ 2.5mm). Wire to at least a 30amp

supply via an all-pole disconnection isolator

switch (easily accessible for safety). Only a

qualied electrician should undertake this work.

Overflow:

The drip-tray has a limited capacity and is

designed to handle small spillages and drips.

Wherever possible, we strongly recommend that

it is connected to a permanent waste.

We have provided two overow outlet/

connection points to choose from;

1). FRONT via drip-tray

If this option is used for the overow, we

can supply a 15mm tting kit (Pt. No: DTK2)

available from Instanta Spares Department

(01704 502905).

2). REAR via outlet at back of machine

If rear overow option is preferred, the front

overow-outlet (see diagram below), must be

blocked o using the tapered–rubber blanking

bung provided. Pipework should then be

provided between the back of the machine

[1/2”bsp – 15mm], and a suitable waste/drain.

NOTE: An air gap must be provided within

300mm of the connection point. Failure to

provide an air gap within this distance could

cause an air lock which could stop the water

discharging in the event of an overow.

3

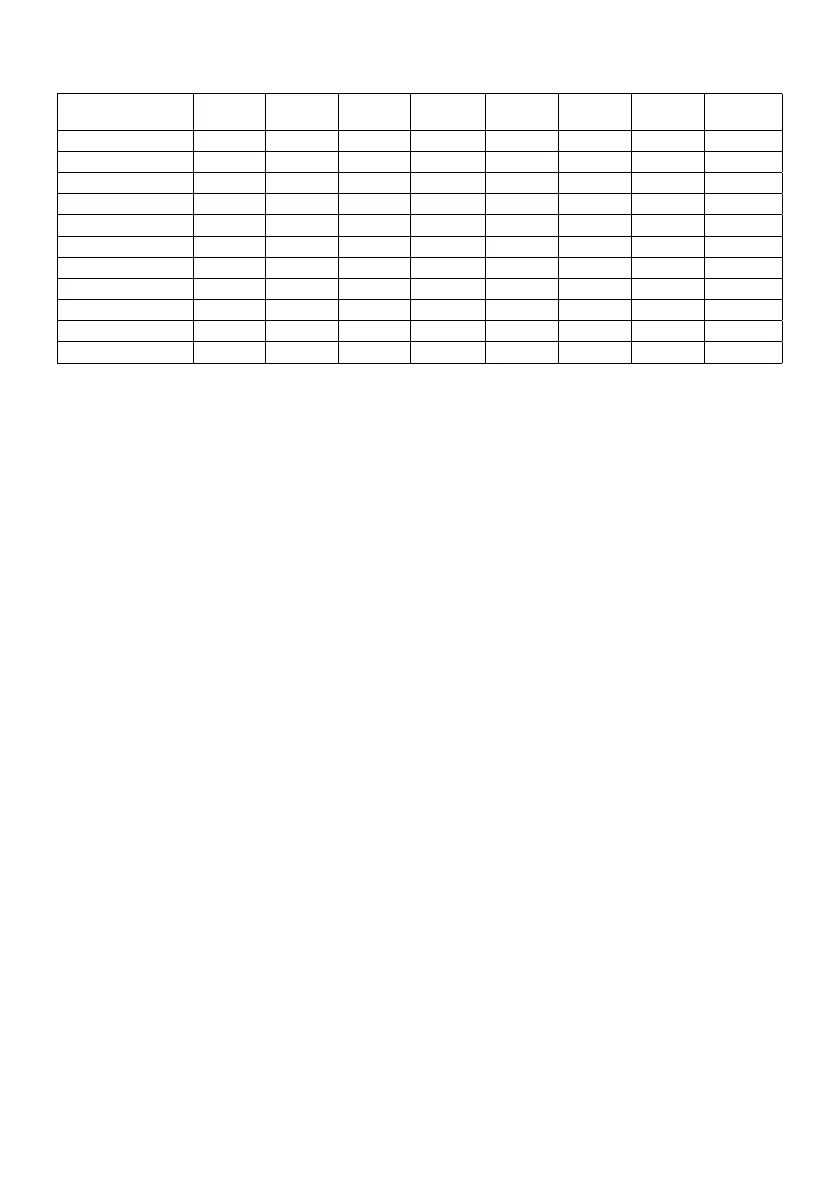

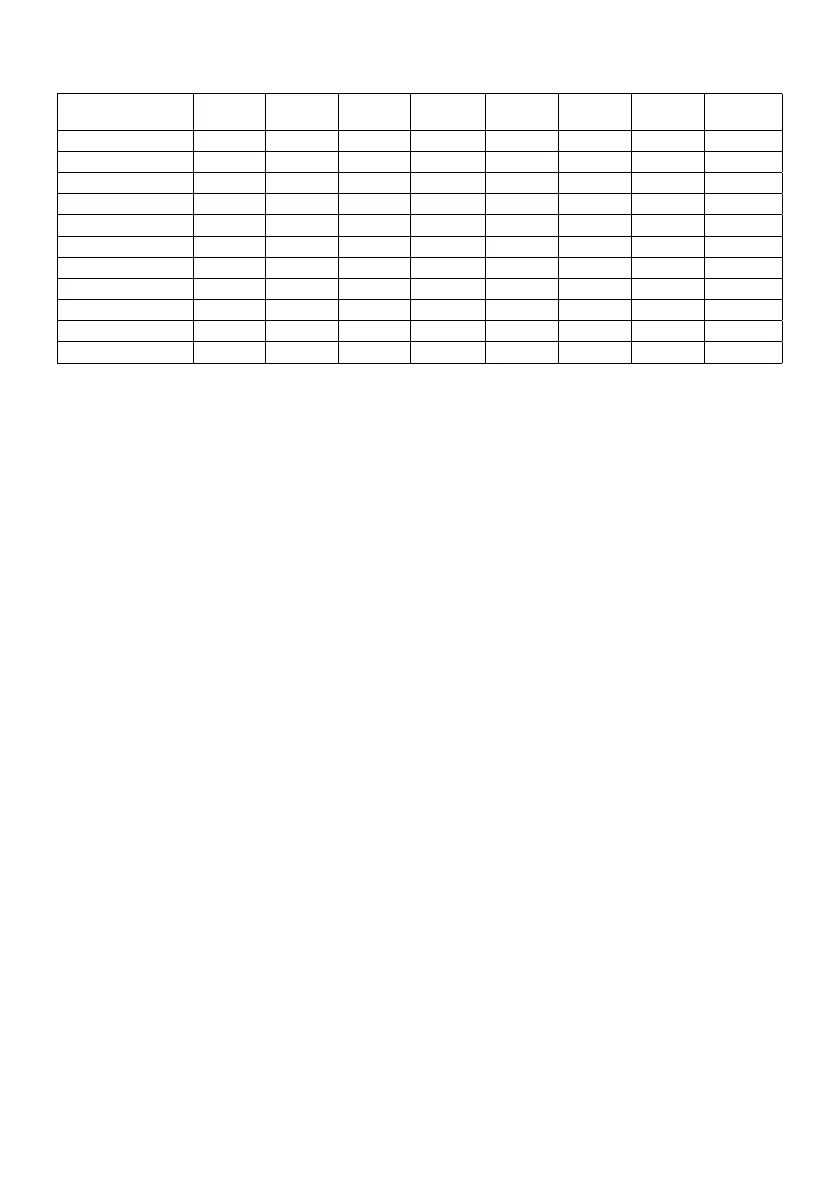

Model Width Depth Height Tap

Clearance

Power

Rating

Weight

(empty)

Weight

(full)

Water Inlet

Pressure

mm Mm Mm mm kW KG KG Bar

CPF2100

260 555 610 200 3.0 15.3 29.1 2 to 7

CPF4100-3

360 555 610 200 3.0 17.5 39.0 2 to 7

CPF4100-6

360 555 610 200 6.0 17.8 39.3 2 to 7

CPF6100

440 555 610 200 6.0 21.4 53.0 2 to 7

High-tap units:

CPF210

260 555 705 304 3.0 16.3 30.1 2 to 7

CPF310

260 555 705 304 6.0 16.8 30.6 2 to 7

CPF510

360 555 705 304 3.0 18.0 39.5 2 to 7

CPF520-3

360 555 705 304 3.0 18.5 40.0 2 to 7

CPF520-6

360 555 705 304 6.0 18.8 40.3 2 to 7

Technical Specification

Loading...

Loading...