Interklima High wall unit

II/IO - SCV1

34

6.

Before performing recommended maintenance, be sure the unit

main power switch is turned off. Failure to do so may result in an

electric shock or injury from the rotating fan blade.

SERVICE (PACK) VALVES - The service valves in the condensing

unit come from the factory closed. This means the refrigerant

charge is isolated from the line side of the connection ports. The

service valves must be opened (turned counter clockwise until

seated) before the service port caps can be removed and the

hoses of the gauge manifold connected. In this position, the

refrigerant has access from and through the outdoor and indoor

unit. The service valves can not be field repaired.

PUMP-DOWN PROCEDURE - The system may be pumped down

in order to make repairs on the low side without losing the

complete refrigerant charge.

1. Attach a pressure gauge to suction service valve gauge port.

2. Frontseat (close) the liquid line valve.

3. Start unit and run until suction pressure reaches 35 Kpa.

4. Shut unit off and frontseat (close) suction valve.

5. Vent remaining pressure.

TABLE 1: CHARGING TABLE

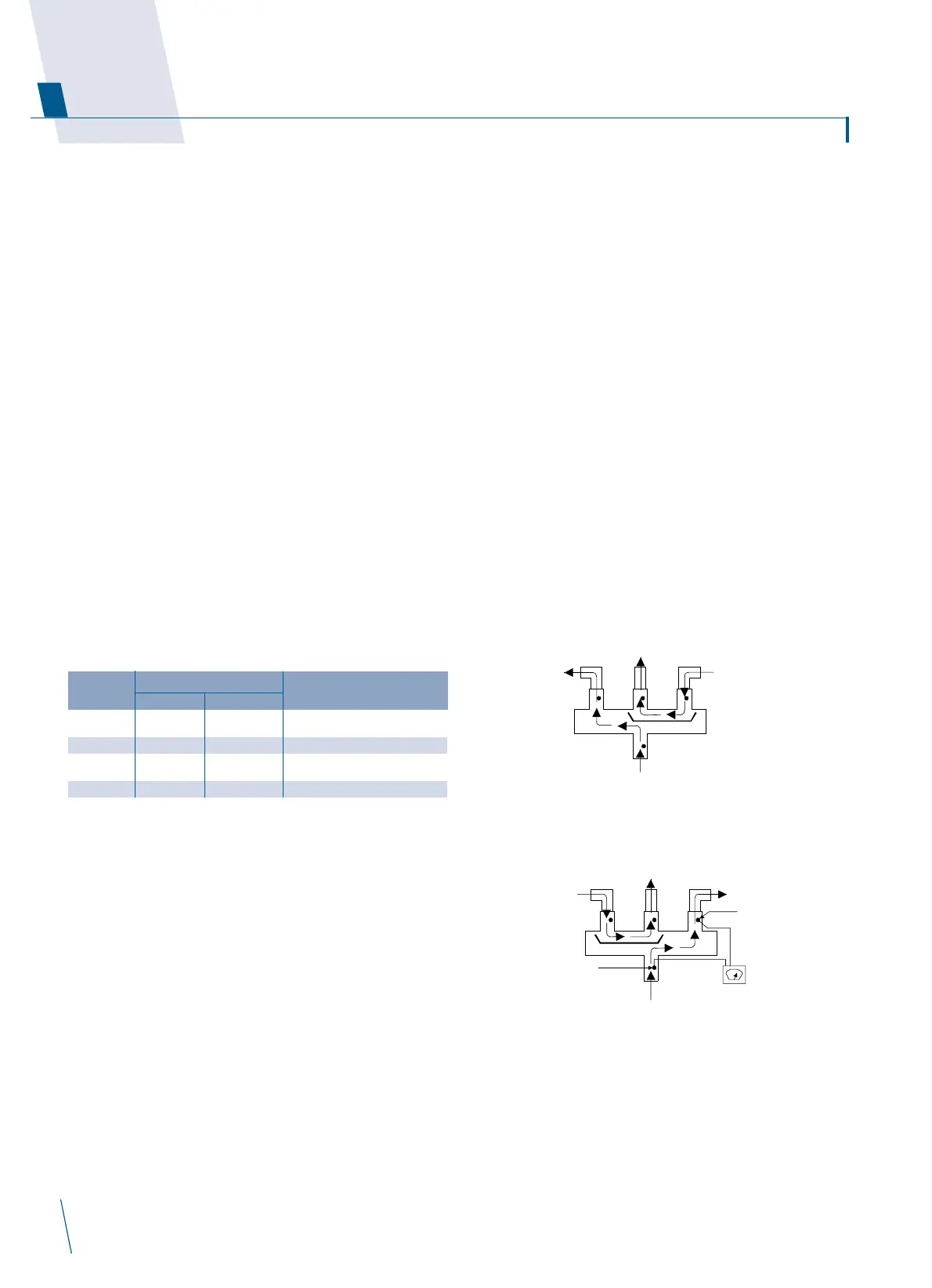

SERVICE (PACK) VALVES - see liquid and suction valve as shown

in fig. 3&4 - The service valves in the condensing unit come from

the factory closed. This means the refrigerant charge is isolated

from the line side of the connection ports.

The service valves must be open (turned counter clockwise until

seated) before the service port caps can be removed and the hoses

of the gauge manifold connected. In this position, the refrigerant has

access from and through the outdoor and indoor unit. The service

valves cannot be field repaired, there fore only a completed valve or

valve system and service caps are available for replacement.

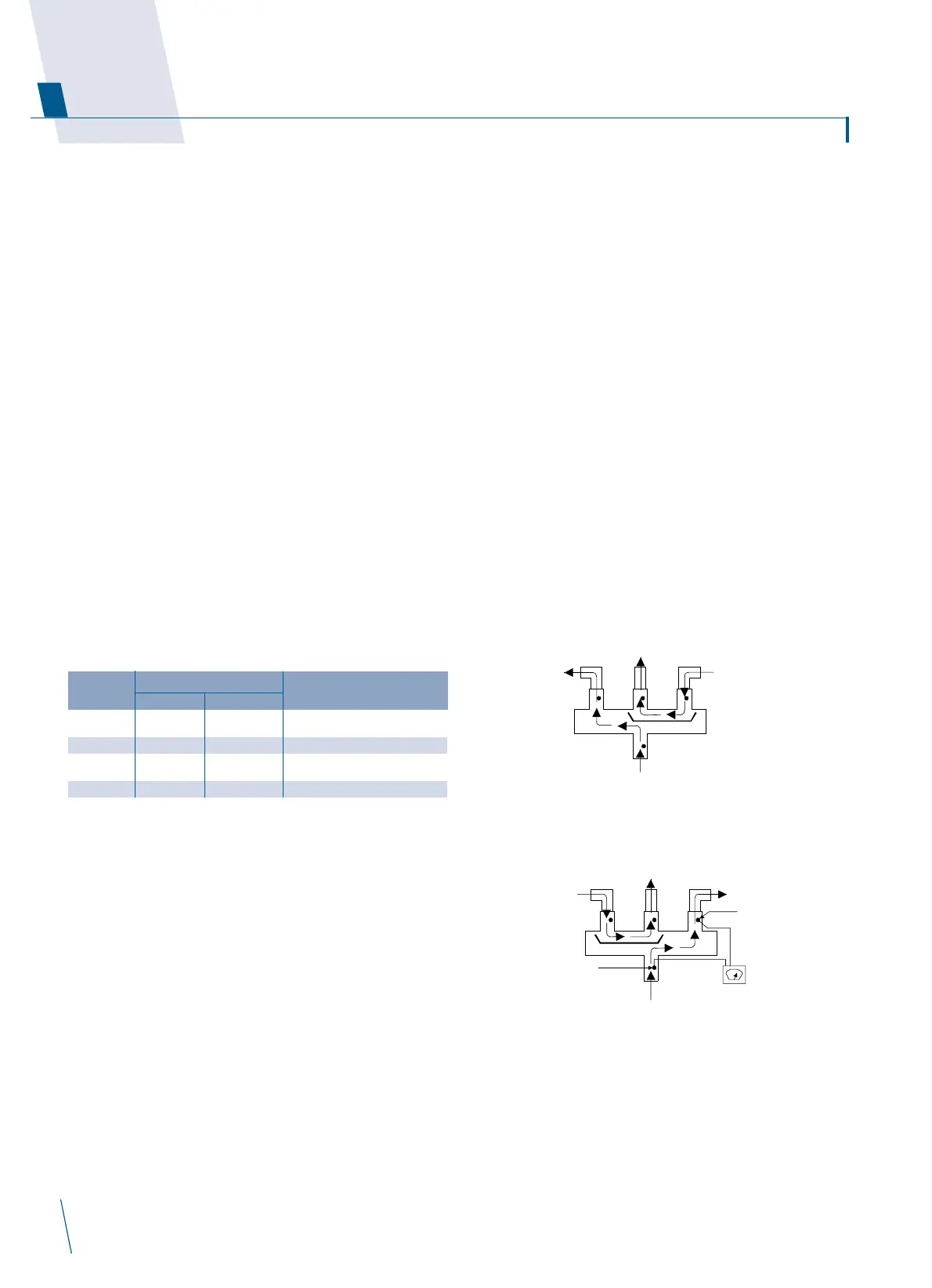

REVERSING VALVE- In heat pumps, the change over between

heating and cooling modes is accomplished with a valve that

reverses the flow of refrigerant in the system. The reversing valve

solenoid can be checked when the power is off with an ohm

meter. Check for continuity and shorting to ground. With the

control circuit (230V) power on, check for the correct voltage at

the solenoid coil. Check for a burned or overheated solenoid. With

the unit operating, other items can be checked, such as frost or

condensate water on the refrigerant lines.

Using a remote measuring device, check the inlet and outlet line

temperatures. Do not touch the lines. if the reversing valve is

operating normally, the inlet and outlet temperatures on the

appropriate lines should be close. Any difference would be due to

heat loss or gain across the valve body. Temperatures are best

checked with a remote reading electronic type thermometer with

multiple probes.

Figures 3 and 4 show test points (tp) on the reversing valve for

recording temperatures. Insulate points for a more accurate

reading. If the valve is defective; shut off all power to the unit and

remove all charge from the system. Remove the valve using a

tubing cutter. Wrap the new valve with a wet rag to prevent over

heating while brazing.

REVERSING VALVE IS ENERGISED WHEN CHANGING FROM

COOL TO HEAT MODE OR FROM HEAT TO DEFROST MODE

After the valve is brazed in, check for leaks, evacuate and charge

system. Operate the system in both heat and cool modes several

times to be sure the valve functions properly.

Service

PACK VALVE SYSTEM CHARGE (kg)

MODEL GAS LIQUID IO (R-410A)

II-09 3 / 8" 1 / 4" 0.98

II-12 1 / 2" 1 / 4" 1.10

II-18 1 / 4" 1 / 4" 1.30

II-22 5 / 8" 3 / 8" 1.65

Loading...

Loading...