-10-

Operation Of The Heater

1. Burn wood or wood products only. The wood should be well

seasons prior to use for maximum efciency.

2. Provide air into the room for combustion.

3. Do Not touch the heater after ring until it has cooled.

4. Do Not use a grate or elevate re, build re directly on hearth.

The fuel feed door must remain closed during operation.

Chimney Connection

MASONRY CHIMNEY

The masonry chimney must comply with UL, ULC codes. Before using

an existing masonry chimney, clean the chimney and inspect the ue

liner to be sure it is safe to use. Make repairs before attaching the

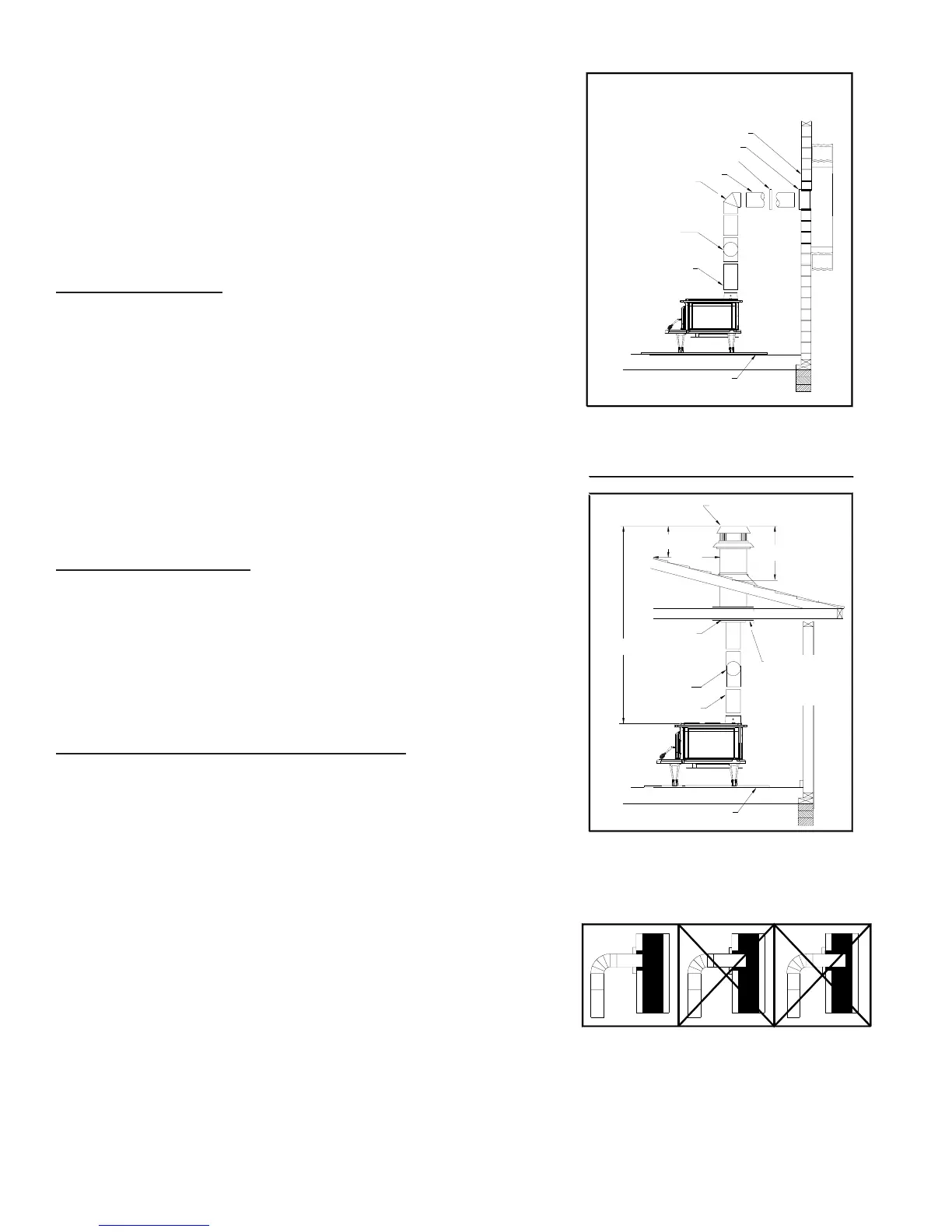

heater. See Page 3, Item 5. Look at Fig. 5. The connector pipe and

ttings you will need to connect directly to a masonry chimney are

shown. If the connector pipe must go through a combustible wall

before entering the masonry chimney, consult a qualied mason or

chimney dealer. The installation must conform to local re codes, and

NFPA 211(USA) or CAN/CSA-B365-M91(CANADA). Do not connect

this heater into the same chimney ue as the replace or ue from

another heater. The chimney used for a heater must not be used to

ventilate the cellar or basement. If there is a clean out opening at the

base of the chimney, close it tightly.

UL/ULC LISTED CHIMNEY

Carefully follow chimney manufacturer's instructions. Use only listed

type UL 103 HT or ULC 629, 6-in diameter black or blued chimney

connector, minimum 24 gauge steel. If your chimney starts at the

ceiling (Fig. 6), you will need enough 6" pipe to reach the ceiling.

The top of the chimney must be at least 3 feet above the roof and

be at least 2 feet higher than any point of the roof within 10 feet.

(Fig 6). Use double or triple wall pipe for the exterior portion of the

chimney.

RULES FOR CONNECTOR PIPE INSTALLATION

1. Crimped end of the pipe must be installed toward the heater.

The pipe should slide into the ue collar. The pipe should be rmly

attached to the ue collar with 3 screws and sealed with furnace

cement.

2. Slope any horizontal pipe upward toward the chimney at least

1/4 inch for each foot of horizontal run. Horizontal section must

be a minimum of 24" from stove.

3. You must have at least 18" inches clearance between any

horizontal piping and the ceiling.

4. The pipe cannot extend into the chimney ue.(Fig. 7)

5. Seal each connector pipe joint with furnace cement. Also, seal

the pipe at the chimney. Seal the inside with high temperature

silicone and the outside with high temperature tape.

6. Use 3 sheet metal screws at each joint to make the piping rigid.

7. It is recommended that no more than two (2) 90 degree bends

be used in the stove pipe installation as more than two (2) may

decrease the amount of draw and possibly cause smoke spillage.

NOTE: The chimney connector shall not pass through an attic,

roof space, oor, ceiling, or similar concealed space. Where

passage through a wall or partition of combustible construction

is desired, the installation must conform with CAN/CSA - B365.

FIG. 5

ELBOW

COLLAR

THIMBLE

FLOOR PROTECTOR

FLUE CONNECTION-NON-COMBUSTIBLE WALL

PIPE

NONCOMBUSTIBLE WALL

PIPE

BAROMETRIC

DRAFT REGULATOR

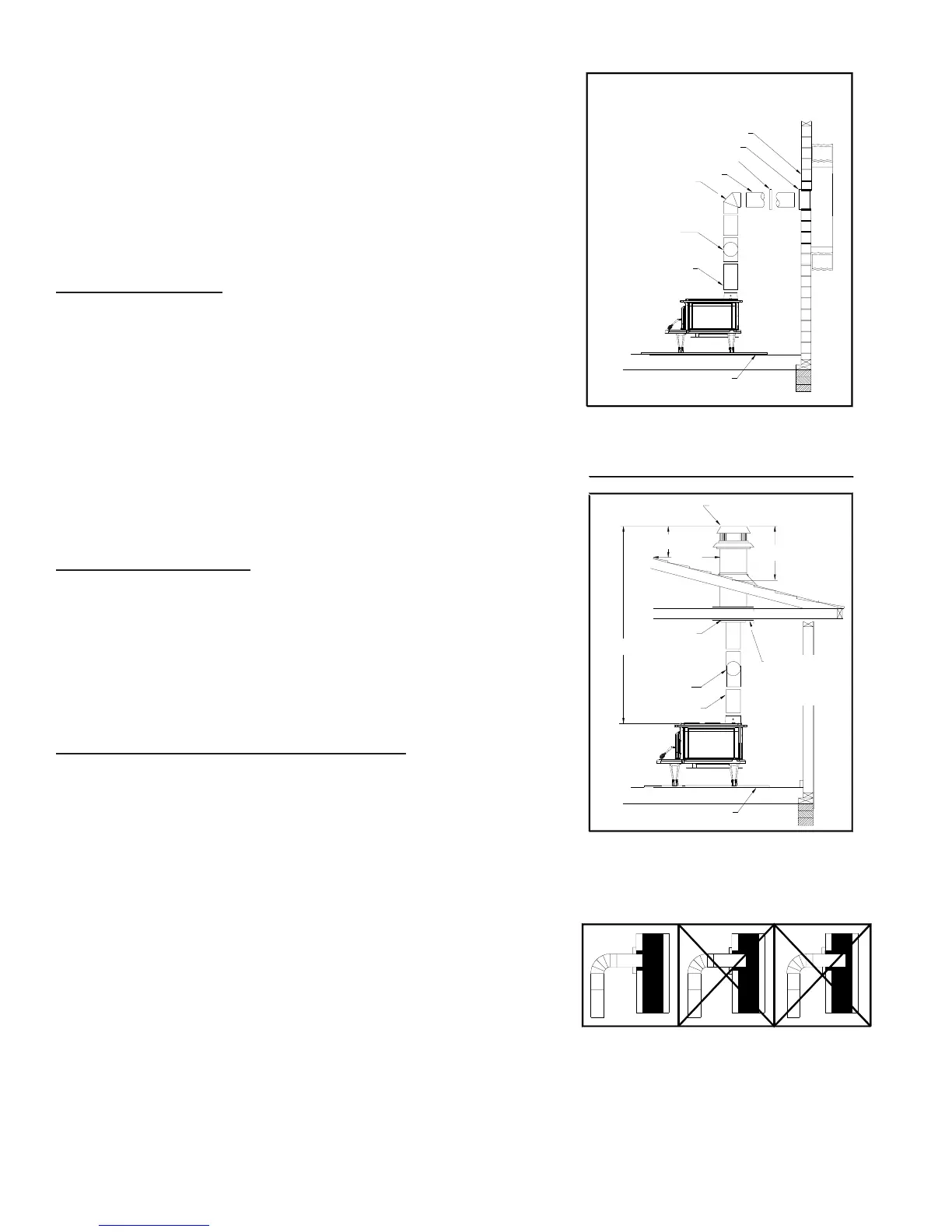

FIG. 6

PIPE REDUCER

FLOOR PROTECTOR

3 FT. MIN.

2 FT. MIN

10 FT.

CHIMNEY CAP MANDATORY

11 FT. MINIMUM

FIG. 7

WRONG

FLUE CONNECTION-NON-COMBUSTIBLE WALL

PIPE

NONCOMBUSTIBLE WALL

PIPE

BAROMETRIC

DRAFT REGULATOR

BAROMETRIC

DRAFT REGULATOR

PIPE

NONCOMBUSTIBLE

CONSTRUCTION IN

ACCORDANCE WITH

NFPA 211

WRONG

RIGHT

FIG. 6

FIG. 5

ELBOW

COLLAR

THIMBLE

PIPE REDUCER

FLOOR PROTECTOR

FLOOR PROTECTOR

3 FT. MIN.

2 FT. MIN

10 FT.

CHIMNEY CAP MANDATORY

11 FT. MINIMUM

FIG. 7

WRONG

FLUE CONNECTION-NON-COMBUSTIBLE WALL

PIPE

NONCOMBUSTIBLE WALL

PIPE

BAROMETRIC

DRAFT REGULATOR

BAROMETRIC

DRAFT REGULATOR

PIPE

NONCOMBUSTIBLE

CONSTRUCTION IN

ACCORDANCE WITH

NFPA 211

Loading...

Loading...