GB

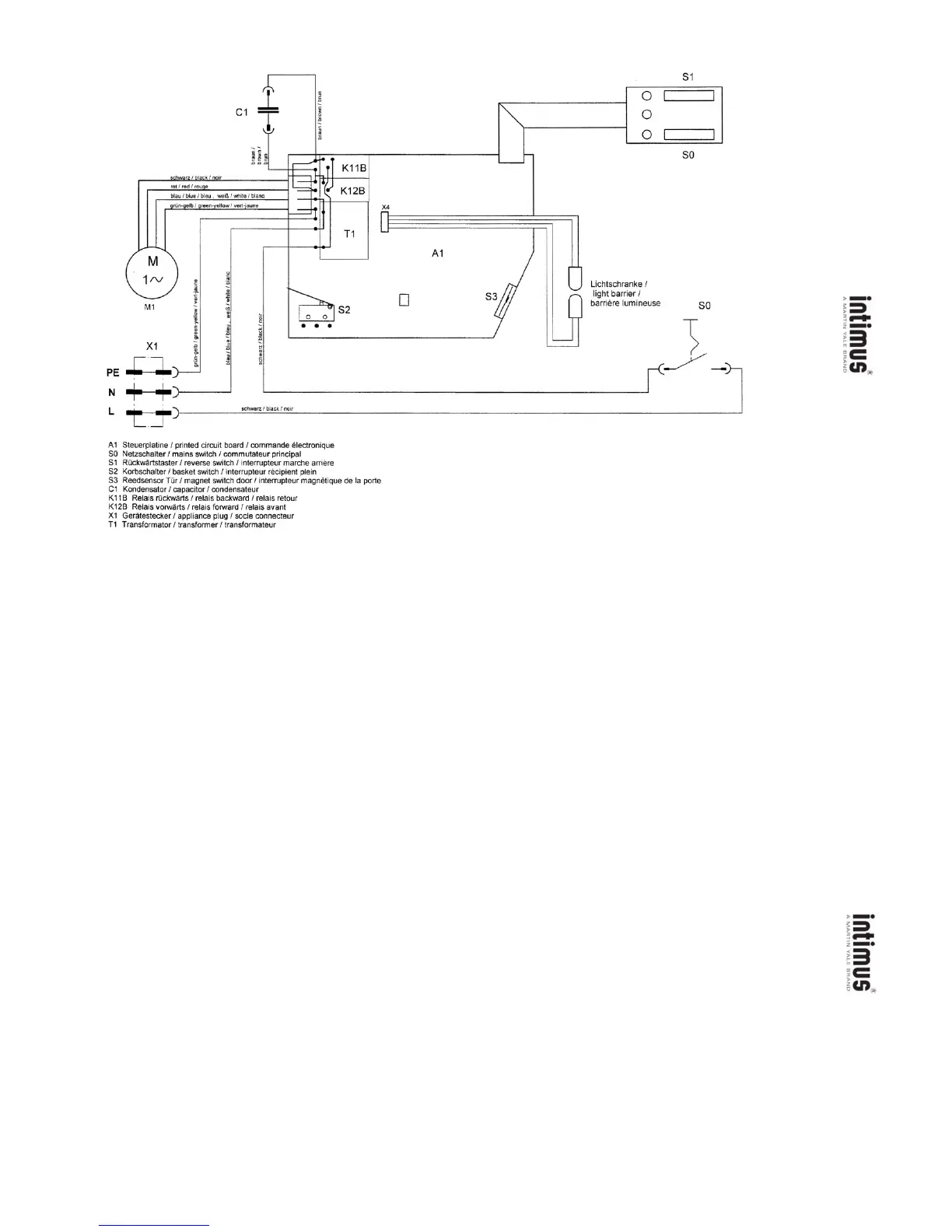

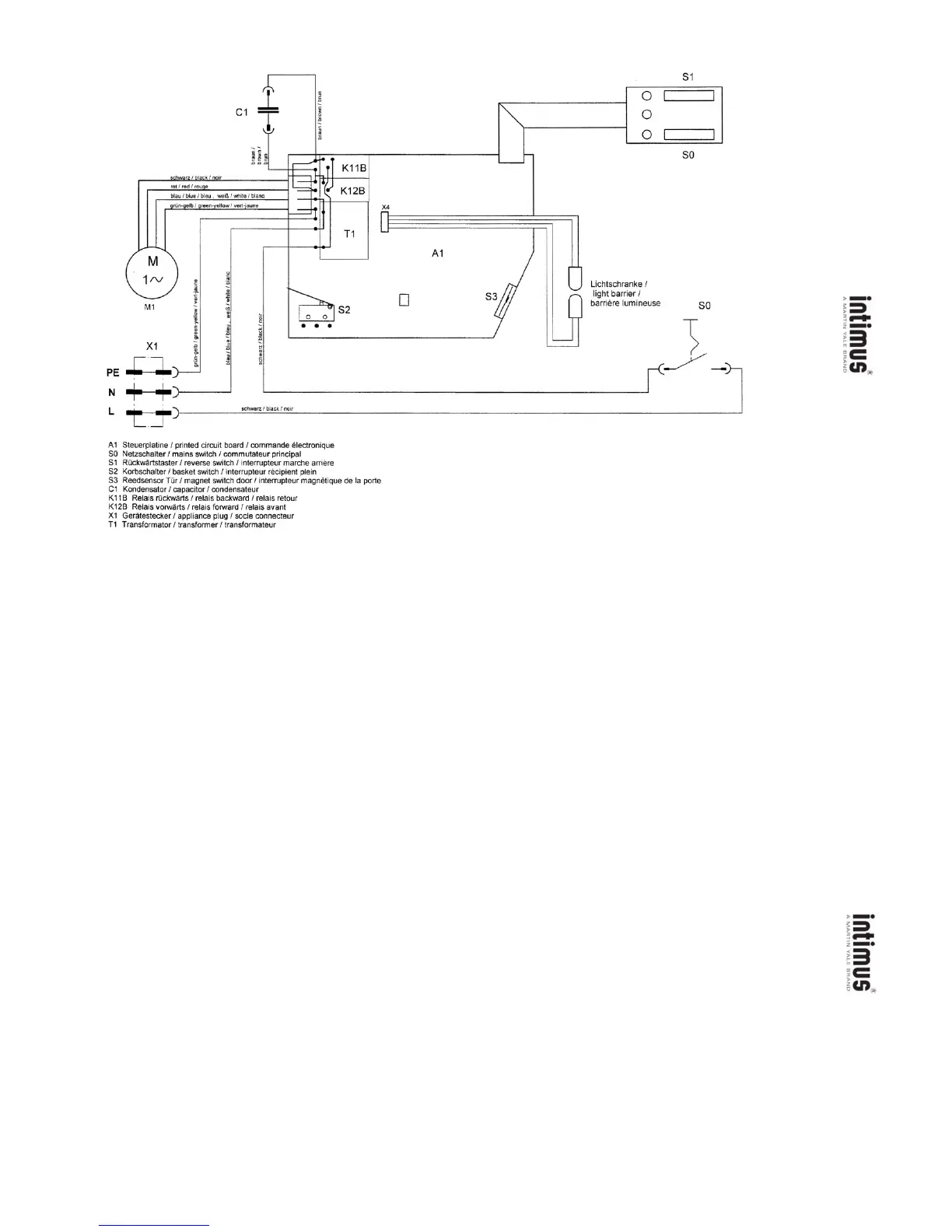

SCHALTBILD / WIRING DIAGRAM / PLAN DE MONTAGE / SCHAKELSCHEMA

DIAGRAMA ELÉCTRICO / ESQUEMA ELECTRICO / SCHEMA ELETTRICO

302/302CC // 402/402CC/402HS

16

MAINTENANCE

COMPENSATION OF THE LIGHT BARRIER:

In order to eliminate malfunctions due to changing

light conditions at the inlet aperture (e.g. by

changing the location) or due to the wear of the

fotocell (scratches), the sensitivity of the light

barrier is automatically re-adjustedby the machine

for the detection of "normal" paper in regular

intervals.

This so called "compensation" can also be carried

out manually in accordance with the sequence

described in the following (e. g. after change of the

light barrier or the PC Board).

The "receptacle full" switch-off must not be

activated for the re-adjustment. The procedure is

as follows:

1. Switch off the maschine at the pushbutton

switch (1) and open the door.

2. Press the pushbutton switch "reverse" (3) and

keep it pressed.

3. Press the "ready" pushbutton switch (1).

4. Release the "reverse" pushbutton switch (3)

after approx. 3 sec.

5. (This process is only required for the cross-cut

models. (CC/HS/SX))

Push switching flap „receptacle full“ backwards

for at least 3 sec.

6. Close the door after approx. 3 sec.

7. Cover the light barrier with a piece of paper (do

not feed the paper up to the cutter) and wait until

the motor is switched on.

This completes the compensation. The machine

is now ready for operation.

Note: If the compensation process has been

interfered with due to exessive external incident

light (direct sun light, lamps, spots etc.) or due to

a false procedure, keep the external light away

from light barrier and re-start the compensation

process right from the beginning.

CLEANING THE PHOTOCELLS:

If paper particles should come to rest in the inlet

guide (for example after a paper jam) it is possible

that the machine will not turn off, due to the broken

light barrier.

To remove these paper strips and also to clean

the photocell, pass another sheet of paper through

the feed slot, or switch the machine to reverse and

wipe both „eyes“ of the photocell with a brush.

MAINTENANCE CUTTING BLOCK:

(1.9x15 mm, 3.8x24 mm and 0.8x12 mm)

After approximately 30 minutes of continuous

use, run the cutting system in reverse for 15 to 20

seconds and spray some of the enclosed Special

Oil onto the cutting system.

TIP FOR ENERGY SAVING:

Please make sure that the shredder is switched

off over night (pushbutton switch (1) (fig. 1).

MALFUNCTIONS

PAPER JAM:

If too much paper is fed to the cutting system the

machine will react as follows:

-a) 1.9 mm / 3.8 mm / 5.8 mm

The cutting system blocks and then stops.

b) 3.8x24 mm / 1.9x15 / 0.8x12 mm

The cutting system blocks, reverses a bit to

release the paper and then stops.

- The motor shuts down automatically.

- The pilot lamp (6) (fig. 1) lights up.

Proceed as follows:

- Briefly operate the pushbutton switch for reverse

(3) (fig. 1).

- The pilot lamp (6) (fig. 1) goes off.

- Remove excess paper from the machine and

continue shredding with less paper.

MOTOR PROTECTION:

The motor shuts down automatically, should it

become overloaded. Turn the machine off with

the pushbutton switch (1) (fig. 1).

Allow the motor to cool down for 15 to 20 minutes

(depending upon room temperature) and then

continue shredding.

CHECKLIST IN CASE OF MALFUNCTIONS:

If the device does not function, check the following:

- Is the plug connected to the mains?

Mains connection: 2-pole mains switch,

internal appliance plug,

separate power cord

- Is the pushbutton switch (1) on?

- Is the door closed?

- Is the receptacle full?

The receptacle has to be emptied.

- Is there a paper jam?

Follow the instructions under „paper jam“.

- has the motor been overloaded?

Wait until the motor has cooled, and then restart.

If none of the above applies, please contact

your dealer.

ACCESSORIES

Description Order-No.

Plastic bag, 300 x 300 x 700 x 0,018 mm (302/-CC // 402/-CC/-HS) 99925

Plastic bag, 440 x 330 x 950 x 0,05 mm (502/-CC/-HS) 99977

Plastic bag, 600 x 500 x 1000 x 0,05 mm (452/-CC // 602/-CC/-HS // 007SX) 99952

Lubricant, 125 ml bottle (CC/HS/SX) 99943

Feeding mechanism for computer paper (452/-CC // 602/-CC/-HS // 007SX) 81942

Note: For orders of special accessories and spare parts, please contact your dealer.

5

TECHNICAL DATA

Cutting width:

302/402: 1.9 mm (strips)

302/402/452/502/602: 3.8 mm (strips)

302/402/502/602: 5.8 mm (strips)

302CC/402CC/

452CC/502CC/602CC: 1.9x15 mm (cross-cut)

302CC/402CC/

502CC/602CC: 3.8x24 mm (cross-cut)

402HS/502HS/

602HS/007SX: 0.8x12 mm

(high security)

Cutting capacity:

302/402:

1.9 mm: 12-14 sheets (70g/m

2

)

3.8 mm: 17-19 sheets (70g/m

2

)

5.8 mm: 21-23 sheets (70g/m

2

)

302CC/402CC:

1.9x15 mm: 7-9 sheets (70g/m

2

)

3.8x24 mm: 12-14 sheets (70g/m

2

)

402HS: 4-5 sheets (70g/m

2

)

452: 15-17 sheets (70g/m

2

)

452CC: 10-12 sheets (70g/m

2

)

502:

3.8 mm: 23-25 sheets (70g/m

2

)

5.8 mm: 31-33 sheets (70g/m

2

)

502CC:

1.9x15 mm: 13-15 sheets (70g/m

2

)

3.8x24 mm: 16-18 sheets (70g/m

2

)

502HS: 8-10 sheets (70g/m

2

)

602:

3.8 mm: 23-25 sheets (70g/m

2

)

5.8 mm: 27-33 sheets (70g/m

2

)

602CC:

1.9x15 mm: 13-16 sheets (70g/m

2

)

3.8x24 mm: 16-19 sheets (70g/m

2

)

602HS: 8-10 sheets (70g/m

2

)

007SX: 15-17 sheets (70g/m

2

)

Supply voltage: 230V/50Hz

240V/50Hz

120V/60Hz

100V/50/60Hz

Pre-fusing:

230V/240V/50Hz: 10 amps (slow-blow)

120V/100V/50/60Hz: 20 amps (slow-blow)

Working width: 260 mm

302/302CC: 240 mm

402/402CC/402HS: 240 mm

452/452CC: 405 mm

502/502CC/502HS: 260 mm

602/602CC/602HS: 405 mm

007SX: 405 mm

Noise level: approx. 54 dB(A)

Power:

302/302CC: 0.47 kW

402/402CC/402HS: 0.47 kW

452/452CC: 1.1/0.9 kW

502/502CC/502HS: 1.1 kW

602/602CC/602HS: 1.1 kW

007SX: 1.1 kW

Dimensions (WxDxH):

302/302CC: 385x280x635 mm

402/402CC/402HS: 385x280x740 mm

452/452CC: 660x430x880 mm

502/502CC/502HS: 490x380x870 mm

602/602CC/602HS: 660x430x1020 mm

007SX: 660x500x1020 mm

Weight:

302/302CC: ca. 18.5/20 kg

402/402CC/402HS: ca. 19.5/21/21 kg

452/452CC: ca. 60 kg

502/502CC/502HS: ca. 41/43/43 kg

602/602CC/602HS: ca. 60 kg

007SX: ca. 93 kg

!':r.hw::l1"7

J

black

I

nair

rot

I

red

I

rOUQe

C1

i

T

--

§

~

c:

~.aii

S1

I~

01

I

I

0

01

1

l..--h

SO

blau

I

blue

I bleu,

weil!.

I

'Ntlite

I

blanc

arun-oelb

I

Qreen-yellow

I v8rt-iaune

X4

X1

!

~rl

L

J-l-l-.

M

1/V

M1

"

c

~

"

I

~

I

~

'"

~

:0

"

i

'"

.~

3

~

:z5

"

~

:0

~

":0

"g

'"

u

"

:0

~

~

~S2

I~

• • •

o

A1

S3#

J

UJ

Lichtschranke

I

light

barrier

I

barriere

lumineuse

SO

>-.

~=

~

..

z_

•

~3

g:C

>

a

(I),,)

A1

Steuerplatine I printed circuit board I commande electronique

SO

Netzschalter I mains switch I commutateur principal

S1

Ruckwartstaster I reverse switch I interrupteur marche arriere

S2 Korbschalter I basket switch I interrupteur recipient plein

S3 Reedsensar

lOr

I magnet switch door I interrupleur magnetique de

la

porte

C1

Kondensator I capacitor I condensateur

K

11

B Relais ruckwarts I relais backward I relais retour

K12B Relais vorwarts I relais forward I relais avant

X1

Geratestecker I appliance plug I sacle connecteur

T1

Transformator I transformer I transformateur

>_.

~=

~

..

z-.

~3

g:C

>

a

(I),,)

Loading...

Loading...