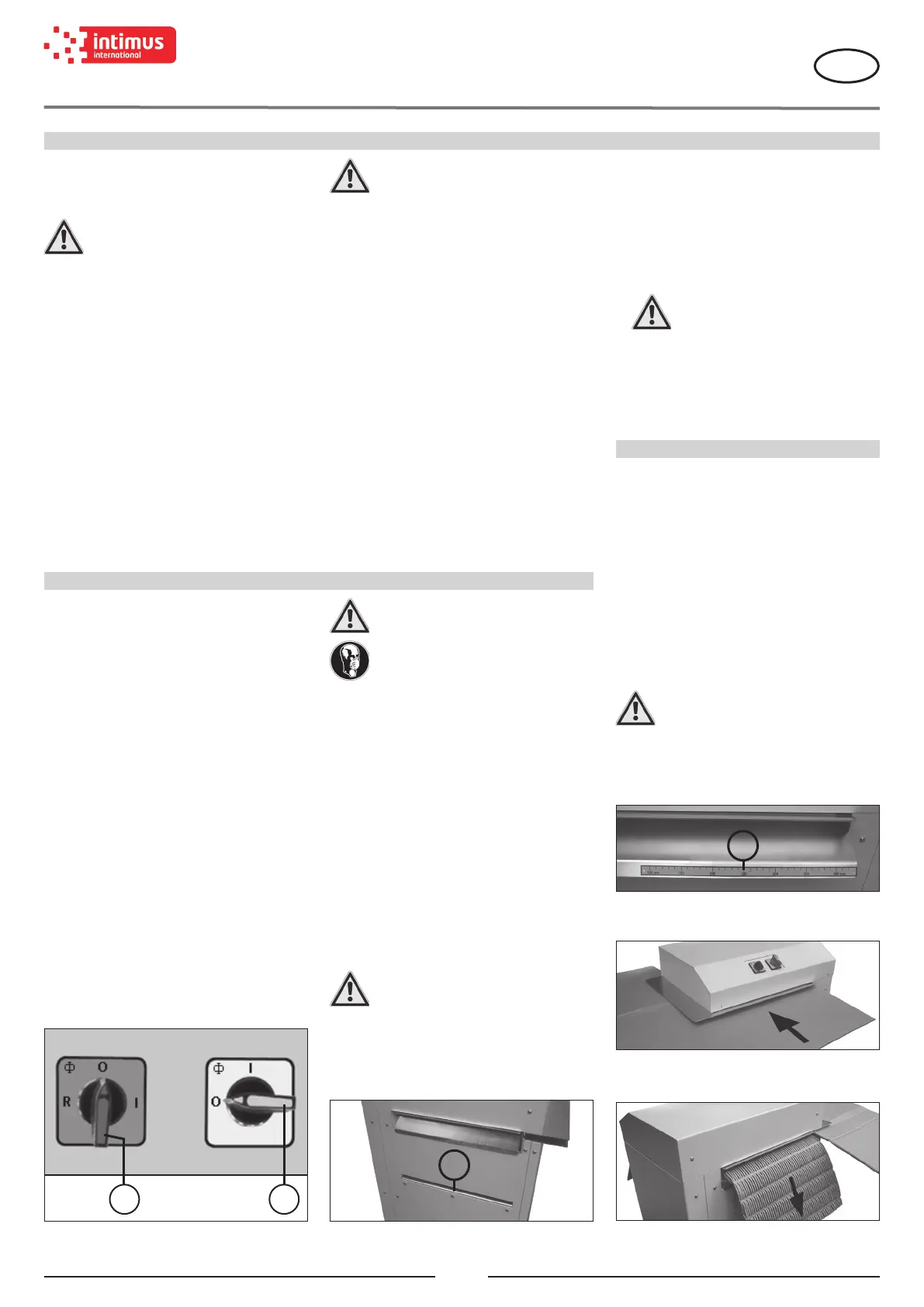

CONTROL PANEL:

1= MainsSwitch(emergencystop)(g.1)

The machine is turned on and off with this

in the event of danger.

2= SelectorSwitch(g.1)

a)„CuttingSystemForward“(„I“)

and materials can be fed into the machine.

The switch remains in this position.

b)„StopCuttingSystem“(„0“)

When the selector switch is turned to the

and the cutting system is brought to a

standstill.

c)„CuttingSystemReverse“(„R“)

When the selector switch is turned to the

reverse.

Note: The cutting system and the auxiliary

cutters only run in reverse as long as the

-

on.

CUTTING CORRUGATED STRIPS

INTO PACKAGING PADS:

- Feed the pre-cut strips to the special cutting

system for the production of packaging pads

- The board is cut into a packaging pad of up

to approx. 425 mm in width depending on the

working width of the cutting system. Overlong

strips are automatically cut off. The tape measure

(4) attached to the inlet guide serves as a guide

for the required width of the packaging pads

If a materials jam should nevertheless

occur, refer to „MATERIAL JAM IN THE

INLET CHUTE“ under „MALFUNCTIONS“.

If the machine is to be operated

without a directly connected vacuum

cleaner (see under “SPECIAL

ACCESSORIES”), the user must wear

a dust mask!

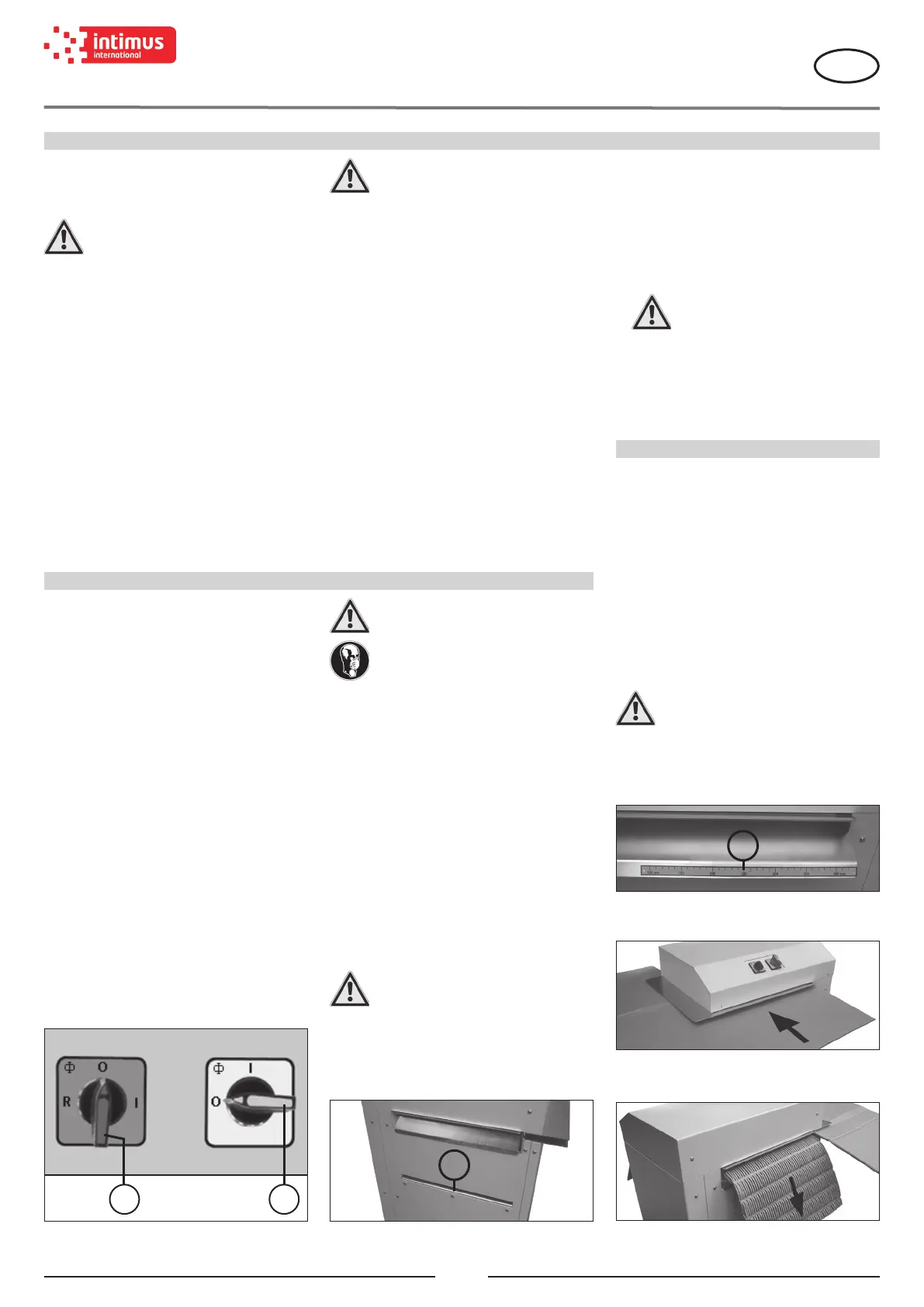

When starting up without a vacuum

cleaner, the dust produced in the

machine when processing the cartons is

led out through a separate opening (3)

(g. 2) on the rear wall of the housing to

the outside into the working environment

of the operator.

OPERATION:

Proceed as follows to start the machine:

1.

position.

2.

position. The cutting system and the auxiliary

cutters are activated.

Note:

Due to danger of injury when later

handling the packaging pads,

existing metal clips and staples must

be removed by means of a suitable

staple remover before cutting into

packaging pads!

APPLICATIONS:

The PacMaster S is used for the manufacture of

packaging pads made from corrugated board or

other carton materials.

The use of other materials may result in

bodily injury (e.g. due to splintering of hard

materials etc.), as well as damage to the

machine (e.g. destruction of the cutting

system etc.).

INSTALLATION REQUIREMENTS:

Note: Be certain that three phase current is

-

pre-fusing of the electrical outlet).

- Plug in the machine.

The machine is approved for

operation at an altitude of up to

1000 m above sea level and relative

humidity of up to 50% with an outside

temperature of 40° C.

POWER SUPPLY CONNECTION:

a)

safely activate the upstream overcurrent protec-

tor according to its triggering characteristics in

the pre-set cut-off time.

b) The conductor cross-section of the power

supply line should be of a magnitude so as

to cause a 15% voltage drop in the case of a

machine blockage (inhibit current = 6 x nominal

current).

CHECKING THE RUNNING DIRECTION:

1.

2.

The cutting system starts running.

3.

correct direction according to the stipulated

input direction of the carton (see direction arrow

power plug if necessary.

the machine.

4

Fig. 1

12

Fig. 5

Fig. 4

3

Fig. 3

4

Fig. 2

88034 11 06/15

PacMaster S

INITIAL START UP

OPERATION

MAINS SWITCH

OPERATION

Translation of the Original Operation Manual

Übersetzung der Originalbetriebsanleitung

GB

Loading...

Loading...