20 2020-05

TORNADO

EN 428000747237

Use and maintenance manual

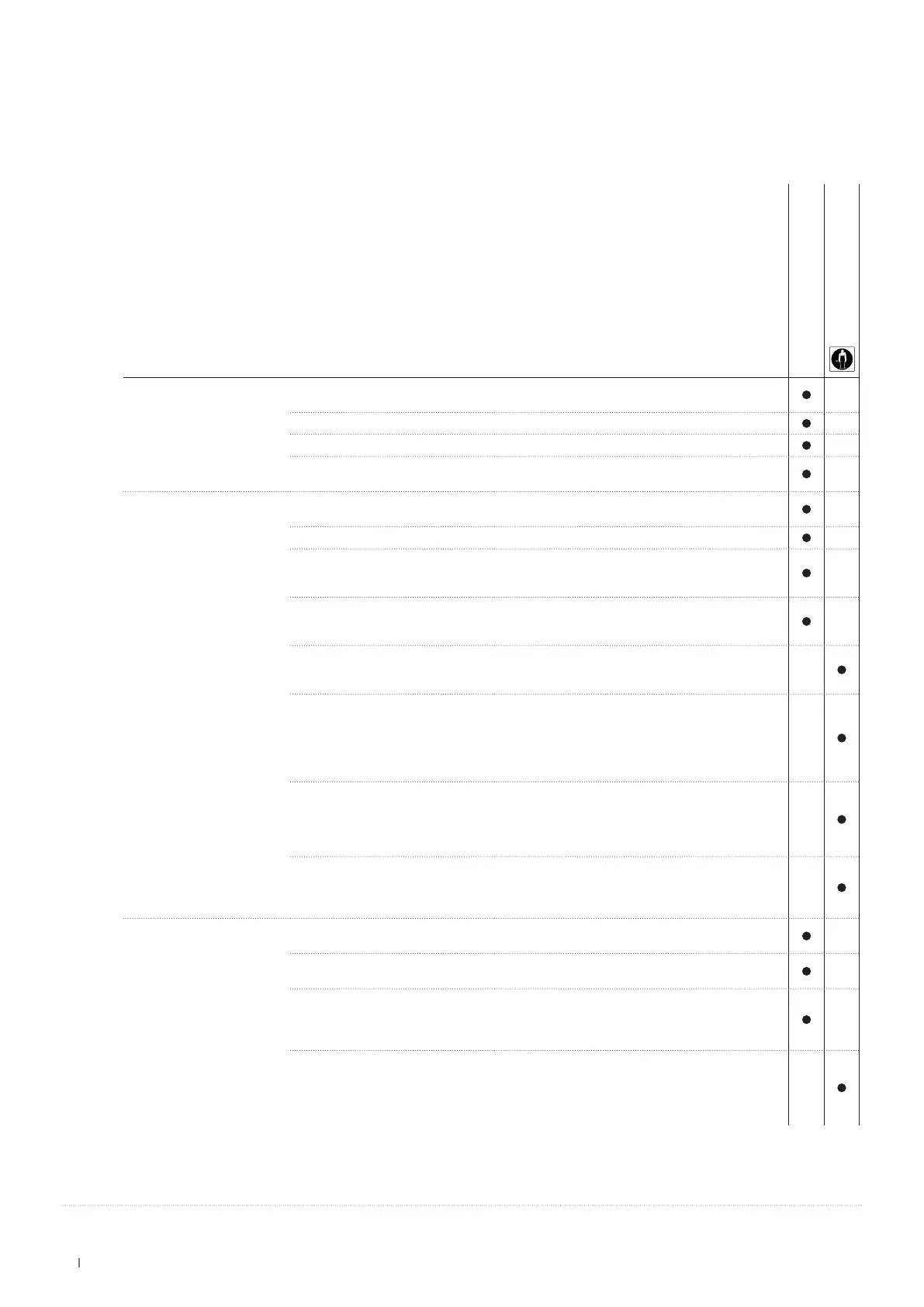

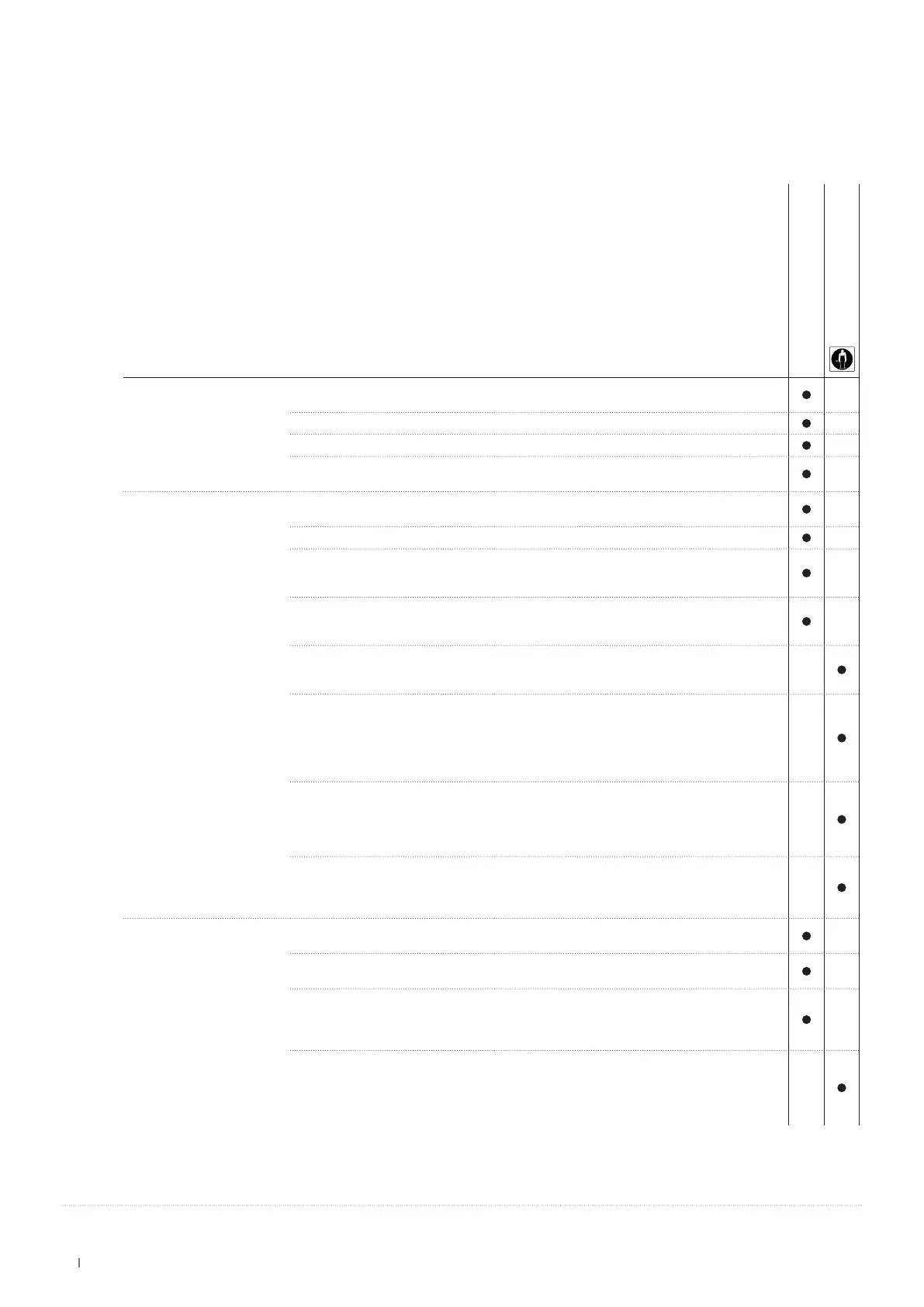

13. FAULTS - TECHNICAL AFTER-SALES ASSISTANCE

In case of uncertain or no operation, before requesting the intervention of the Technical Assistance service

perform the following checks:

MALFUNCTION CAUSE SOLUTION

USER

TECHNICAL ASSISTANCE

THE EQUIPMENT

DOES NOT WORK

Blown protective fuse

First nd the cause of the trip

of the switch, and then replace the new fuse.

The master switch is open Close the master switch.

The plug is not inserted Insert the plug.

Electrical black-out

If the black-out should be prolonged, transfer the prod-

uct into an appropriate cold storage container.

THE TEMPERATURE

IS NOT SUFFICIENTLY

LOW

Evaporator(s) completely blocked with

ice

Carry out an additional defrosting cycle.

Wrong temperature setting Set the appropriate temperature.

Equipment being struck by

currents of air or exposed to

direct or reected sunlight

Remove any draughts and prevent any direct or reected

sunlight.

Insucient air ow for

cooling to the condenser

Remove anything which could obstruct

the circulation of air through the condenser (sheets of

paper, cardboard, insucient slots in grille, etc.).

Internal fans not working

or damaged fans

Replace the ventilators/fans.

Thermostat / Electronic control board

not ecient

Replace the thermostat/electronic control board.

If the electronic control board is used on appliances with

R290 coolant, it must only be replaced with an original

spare part supplied by the manufacturer. Replace the

temperature probes only after having ascertained which

of them is inecient.

Condenser unit blocked by dust

or dirt in general

Clean the condensing unit thoroughly.

The condensing unit in particular operating environ-

ments (e.g. presence of dust, presence of excessive

humidity, etc.) when the performance of the appliance

deteriorates requires careful cleaning.

Insucient refrigerant quantity

in the cooling system

Find the cause of the refrigerant loss and remove it; top

up the refrigerant load

if necessary having emptied

the system.

THE COMPRESSOR DOES

NOT START WORKING

OR WORKS FOR

VERY SHORT PERIODS

No electric power supply

to the appliance

Check if there is a power cut.

Close the various switches on the power supply line.

Power supply voltage

too low

Check that the mains voltage of the power supply cable

corresponds to the nominal value 115V +/- 10%.

Temperature set

too high

If the temperature is higher than the air temperature

in the display chamber, the compressor will not start. Set

a more suitable temperature if the current value is not

low enough.

Maximum pressure

switch intervention (if present)

Check the cause of the continuous interventions of the

maximum pressure switch such as: blocked air condens-

er, air condenser fan stopped, excessively high ambient

temperature, breakage of the pressure switch itself.

Loading...

Loading...