2500_EN_IT_IS_R2_PED

5 di 9

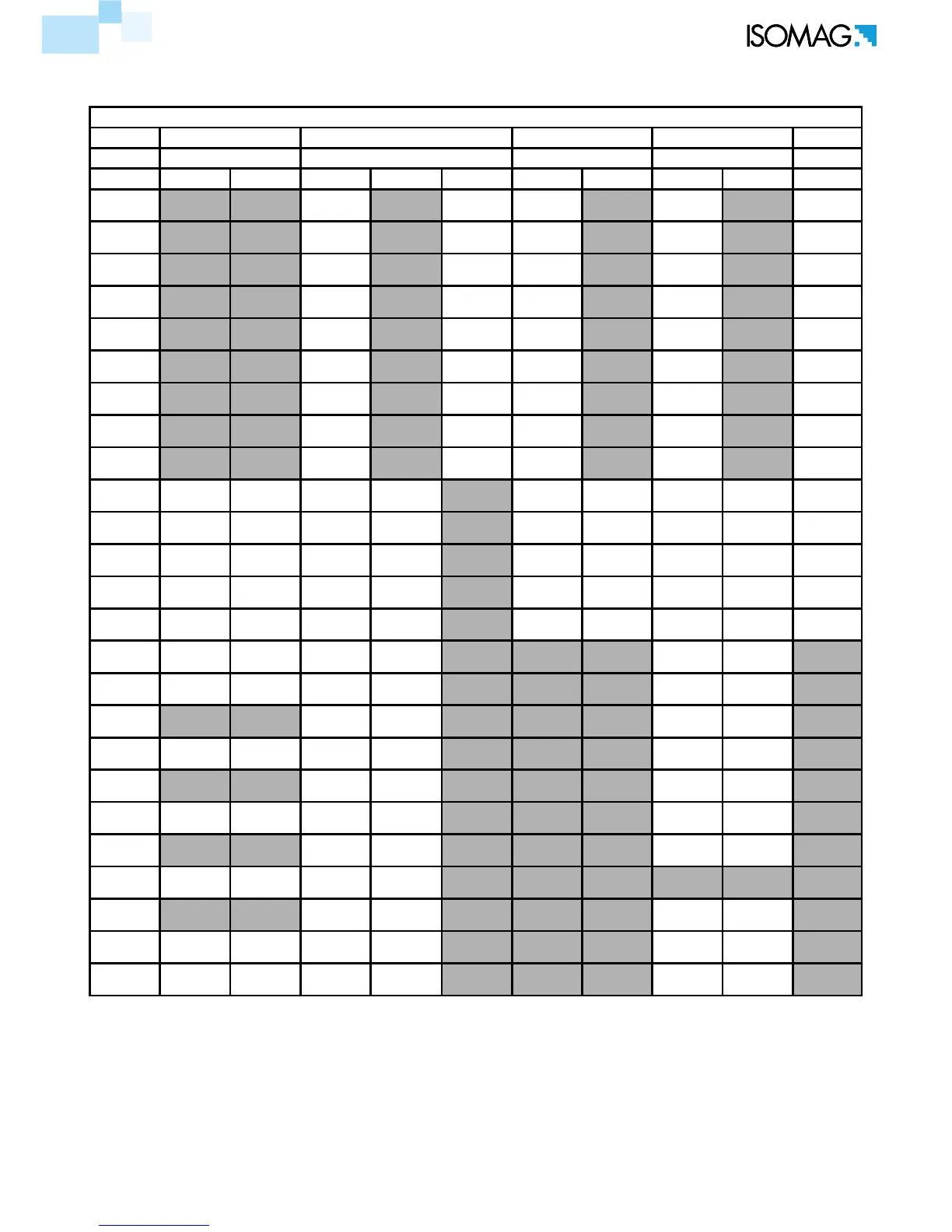

PRESSIONI DI ESERCIZIO

Kpa 1000 1600 2500 4000 6400

psi 140 260 350 600 1000

DN PTFE EBON. PTFE EBON. PP PTFE EBON. PTFE EBON. EBON.

25

25

(21)

19 25

25

[32]

135

[95]

32

43

(26)

28 43

43

[40]

184

[115]

40

53

(32)

36 53

53

[63]

250

[184]

50

68

(60)

52 68

68

[35]

284

[101]

65

90

(78)

75 45

45

[53]

203

[156]

80

53

(89)

41 53

53

[68]

218

[200]

100

59

(70)

56 83

83

[94]

305

[273]

125

77

(94)

71 112

112

[130]

519

[380]

150

108

(106)

106 135

135

[113]

758

[328]

200 148 432

99

(148)

288

(433)

134 391

178

[178]

520

[519]

816

[519]

250 123 359

140

(156)

408

(455)

204 595

267

[185]

780

[540]

1124

[540]

300 142 415

175

(234)

510

(683)

201 588

278

[275]

812

[803]

1108

[803]

350 172 502

205

(325)

598

(946)

324 945

422

[318]

1231

[927]

1684

[927]

400 217 632

282

(312)

821

(911)

426 1243

619

[411]

1805

[1198]

2180

[1198]

450 194 564

281

(336)

981

(926)

[398] [1161]

500 224 652

382

(317)

1113

(924)

[465] [1356]

550 (379) (1105) [608] [1772]

600 323 942

568

(463)

1658

(1350)

[774] [2258]

650 (429) (1251) [753] [2195]

700 356 1040

421

(503)

1230

(1468)

[947] [2761]

750 (451) (1315) [1105] [3223]

800 476 1388 549 1603

850 (563) (1642) [1373] [4006]

900 450 1312

519

(618)

1515

(1803)

[1408] [4106]

1000 582 1699

721

(736)

2105

(2146)

[1598] [4662]

COPPIE DI SERRAGGIO (Nm) PER BULLONI SENSORI FLANGIATI)

• Stringere uniformemente i dadi in sequenze diagonalmente opposte

• Le coppie di serraggio indicate in tabella sono applicabili a ange: EN1092-1, DIN 2501,

BS 4504, ANSI B16.5, JIS

• È consigliabile l’uso di guarnizioni DIN 2690

• Per DN >1000 contattare il produttore

• (***)= ANSI 150

• [***]= ANSI 300

The manufacturer guarantees only English text available on our web site www.isoil.com

2500_EN_IT_IS_R2_PED

5 di 9

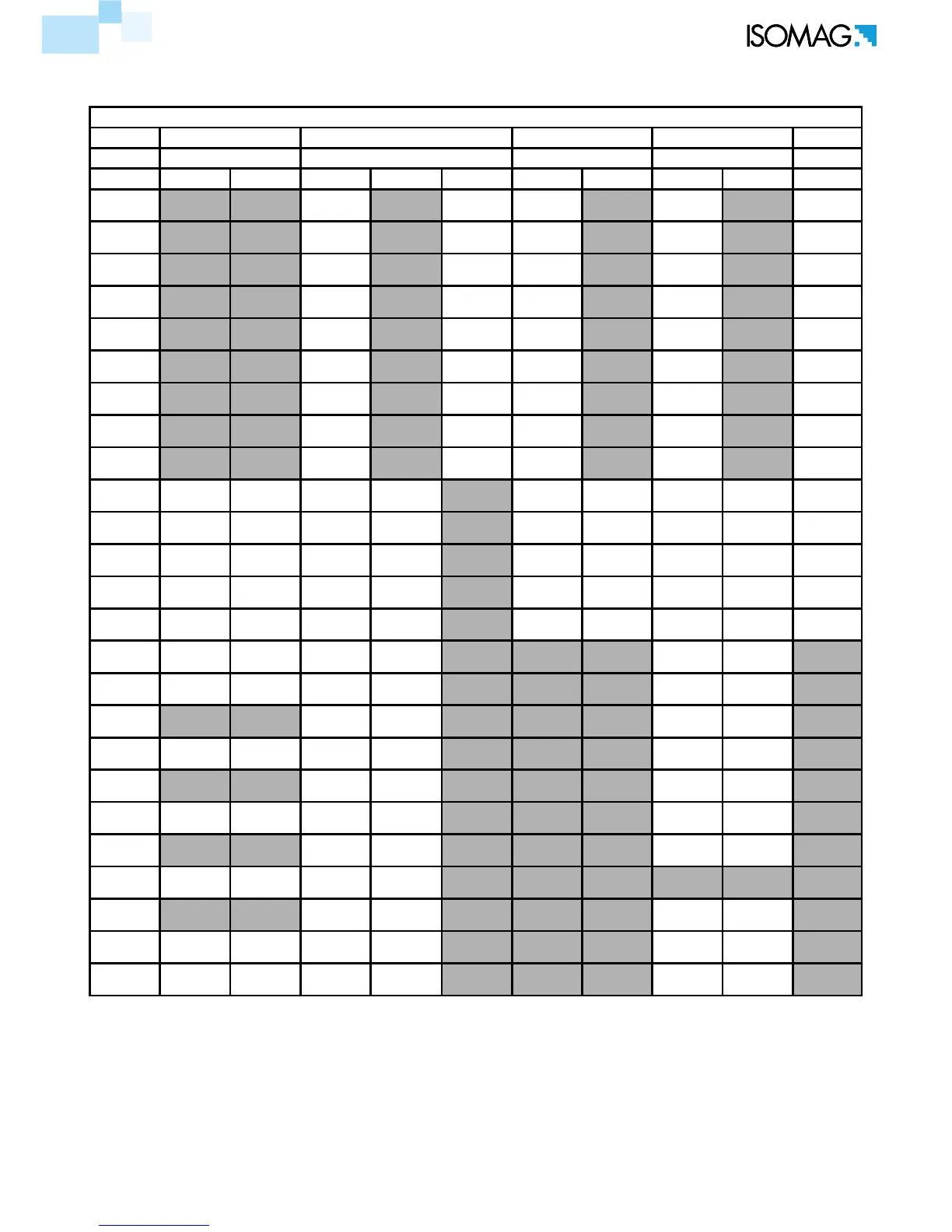

OPERATIVE PRESSURE

Kpa 1000 1600 2500 4000 6400

psi 140 260 350 600 1000

DN PTFE EBON. PTFE EBON. PP PTFE EBON. PTFE EBON. EBON.

25

25

(21)

19 25

25

[32]

135

[95]

32

43

(26)

28 43

43

[40]

184

[115]

40

53

(32)

36 53

53

[63]

250

[184]

50

68

(60)

52 68

68

[35]

284

[101]

65

90

(78)

75 45

45

[53]

203

[156]

80

53

(89)

41 53

53

[68]

218

[200]

100

59

(70)

56 83

83

[94]

305

[273]

125

77

(94)

71 112

112

[130]

519

[380]

150

108

(106)

106 135

135

[113]

758

[328]

200 148 432

99

(148)

288

(433)

134 391

178

[178]

520

[519]

816

[519]

250 123 359

140

(156)

408

(455)

204 595

267

[185]

780

[540]

1124

[540]

300 142 415

175

(234)

510

(683)

201 588

278

[275]

812

[803]

1108

[803]

350 172 502

205

(325)

598

(946)

324 945

422

[318]

1231

[927]

1684

[927]

400 217 632

282

(312)

821

(911)

426 1243

619

[411]

1805

[1198]

2180

[1198]

450 194 564

281

(336)

981

(926)

[398] [1161]

500 224 652

382

(317)

1113

(924)

[465] [1356]

550 (379) (1105) [608] [1772]

600 323 942

568

(463)

1658

(1350)

[774] [2258]

650 (429) (1251) [753] [2195]

700 356 1040

421

(503)

1230

(1468)

[947] [2761]

750 (451) (1315) [1105] [3223]

800 476 1388 549 1603

850 (563) (1642) [1373] [4006]

900 450 1312

519

(618)

1515

(1803)

[1408] [4106]

1000 582 1699

721

(736)

2105

(2146)

[1598] [4662]

TORQUES (NM) FOR FLANGED SENSOR’S BOLTS

• Tighten uniformly in diagonally opposite sequence

• The torque listed in tab are applicable to anges: EN1092-1, DIN2501, BS4504, ANSI

B16.5, JIS

• Is recommended the use of gaskets DIN 2690

• For DN > 1000 contact the manufacturer

• (***)= ANSI 150

• [***]= ANSI 300

Loading...

Loading...