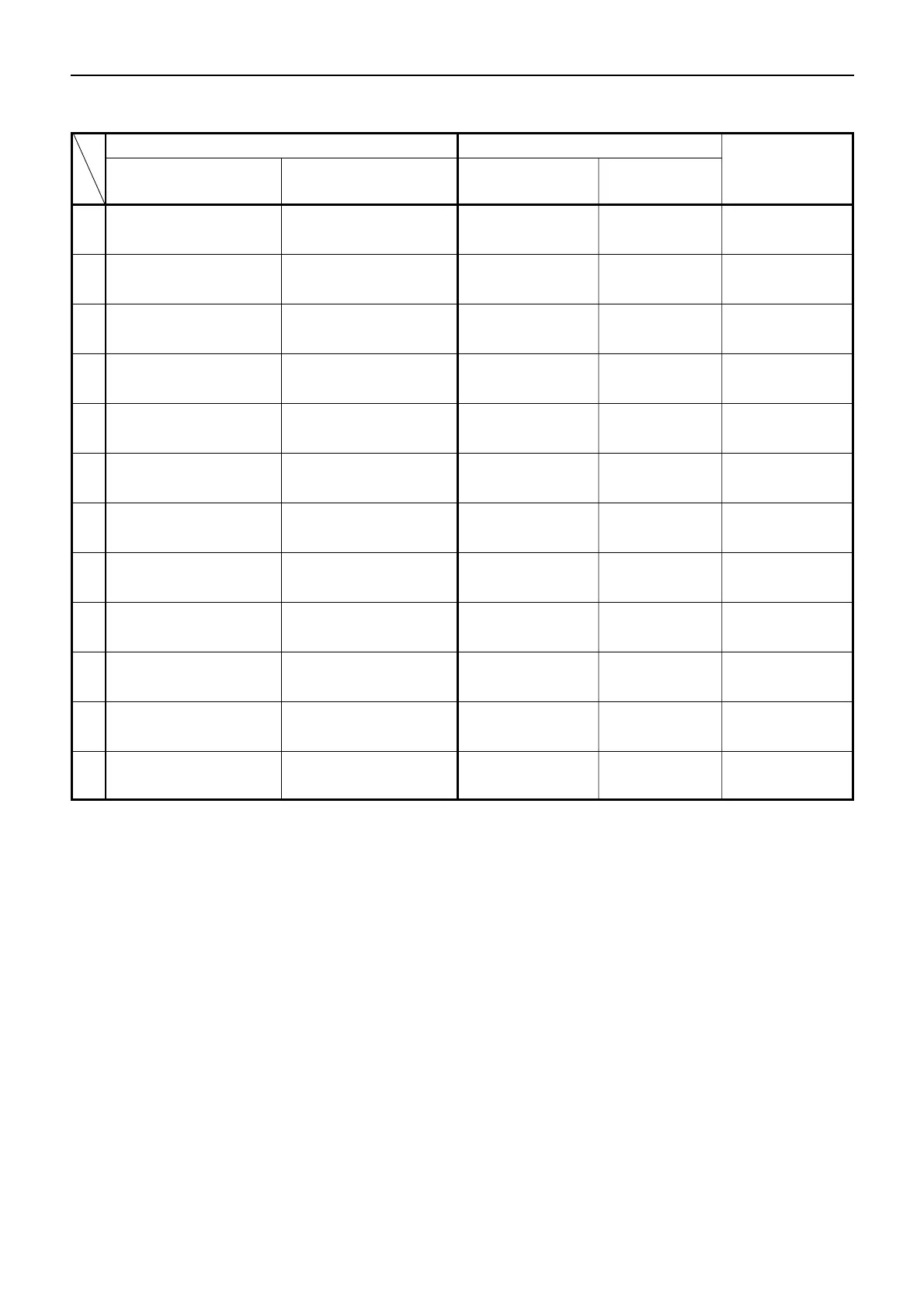

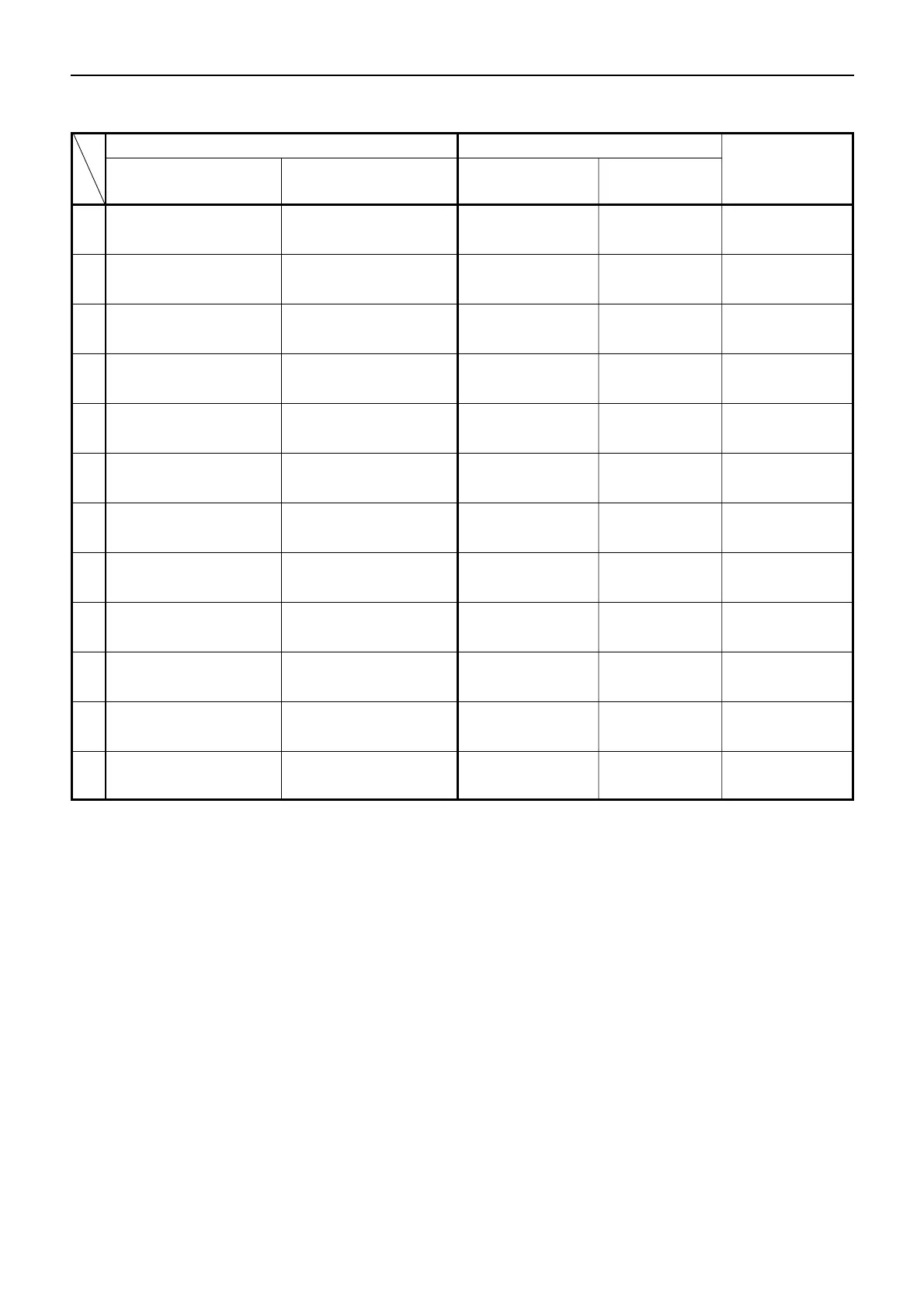

2. LOCATIONS WHERE SEALANT IS APPLIED

Location Condition for use

Name of

Name of part

Name of Object to be Groove to be

mating part sealed applied

sealant

1 Oil pan Cylinder block

Engine oil

Not provided TB1207C

(10W-30)

2 Rocker bracket Cylinder head

Engine oil

Provided TB1207B

(10W-30)

3 Air inlet pipe Cylinder head cover Air Provided TB1207C

4

Front plate

Cylinder block

Engine oil

Provided TB1207B

(with PTO provided) (10W-30)

5

Timing case (with

Front plate

Engine oil

Provided TB1207B

PTO provided) (10W-30)

6

Timing case (with

Cylinder block

Engine oil

Provided TB1207B

no PTO provided) (10W-30)

7 Water pump ASM Cylinder block Cooling water Not provided TB1207C

8

Rear cover;

Body; water pump Cooling water Provided TB1207B

water pump

9

Housing cover;

Cylinder block

Engine oil

Provided TB1207B

injection pump (10W-30)

10 Solenoid; fuel cut Cylinder block

Engine oil

Provided TB1207C

(10W-30)

11 Retainer; oil seal Cylinder block

Engine oil

Provided TB1207B

(10W-30)

12 Indicator; air cleaner Air cleaner Air Not provided (Sealing tape)

Fig. 18

18

GENERAL INFORMATION

Cautions:

1. Always use the above brandnames or an equivalent as the sealant.

2. Since Loctite FMD127 and Three-Bond 1386 are anaerobic, do not use them in case a gap exceeding

0.25 mm is occurring between the metallic mating surfaces since satisfactory effects cannot be

expected.

3. Always use the optimum quantity of sealant. Observe the handling precautions designated for

respective products.

When applying a sealant :

(1) when applying a sealant over a surface where some other liquid gasket was used previously, thor-

oughly clean the reside sealant using a scraper and wipe the surface by waste cloth to remove oil,

moisture, dust, etc. from the surface.

(2) When using the gasket remover “Bundo 391D” made by Three-Bond (Isuzu’s Part No. 1-8840-0542-0)

to facilitate the “cleaning work”, apply the remover and leave it as is for “about 10 minutes” before

starting the removal work.

(3) Be careful not to apply too much or too little.

(4) How to use the TB1207C and TB1207B

Apply them with a line diameter of 3 mm or more and for a thickness of 1 ~ 2 mm.

Apply them along the gluing groove without interruptions and assemble the mating structures with 5

minutes.

Also, after finishing the assembly, leave the assembly as is for at least 2 hours and do not run the

engine during this period.

Loading...

Loading...