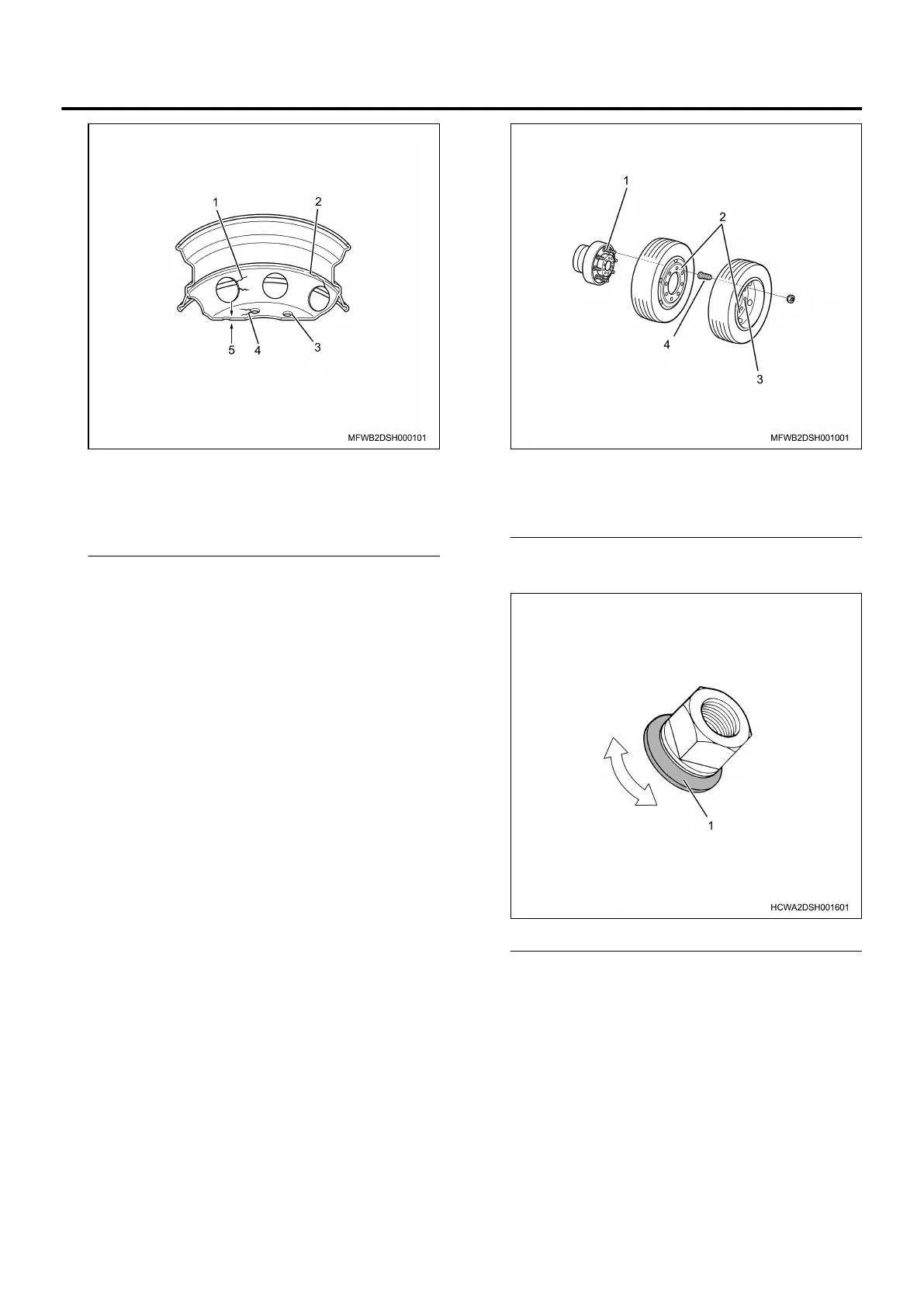

1. Crack or damage of the ornament holes

2. Crack or damage of welds

3. Fatigue of wheel nut contact surface

4. Crack or damage of wheel nut contact surface

5. Crack or damage of hub installation surface

Note:

・ Inspection of wheel bolt and wheel nut

Caution:

・ Clean away any rust and filth. There is a

problem with the screws if they do not turn

smoothly even when you thinly apply engine

oil, gear oil or power steering fluid to the

screws.

・ If there is an abnormality, replace the wheel

bolts and wheel nuts as a set.

・ If the wheel bolts are broken, replace all wheel

bolts and wheel nuts for that axle.

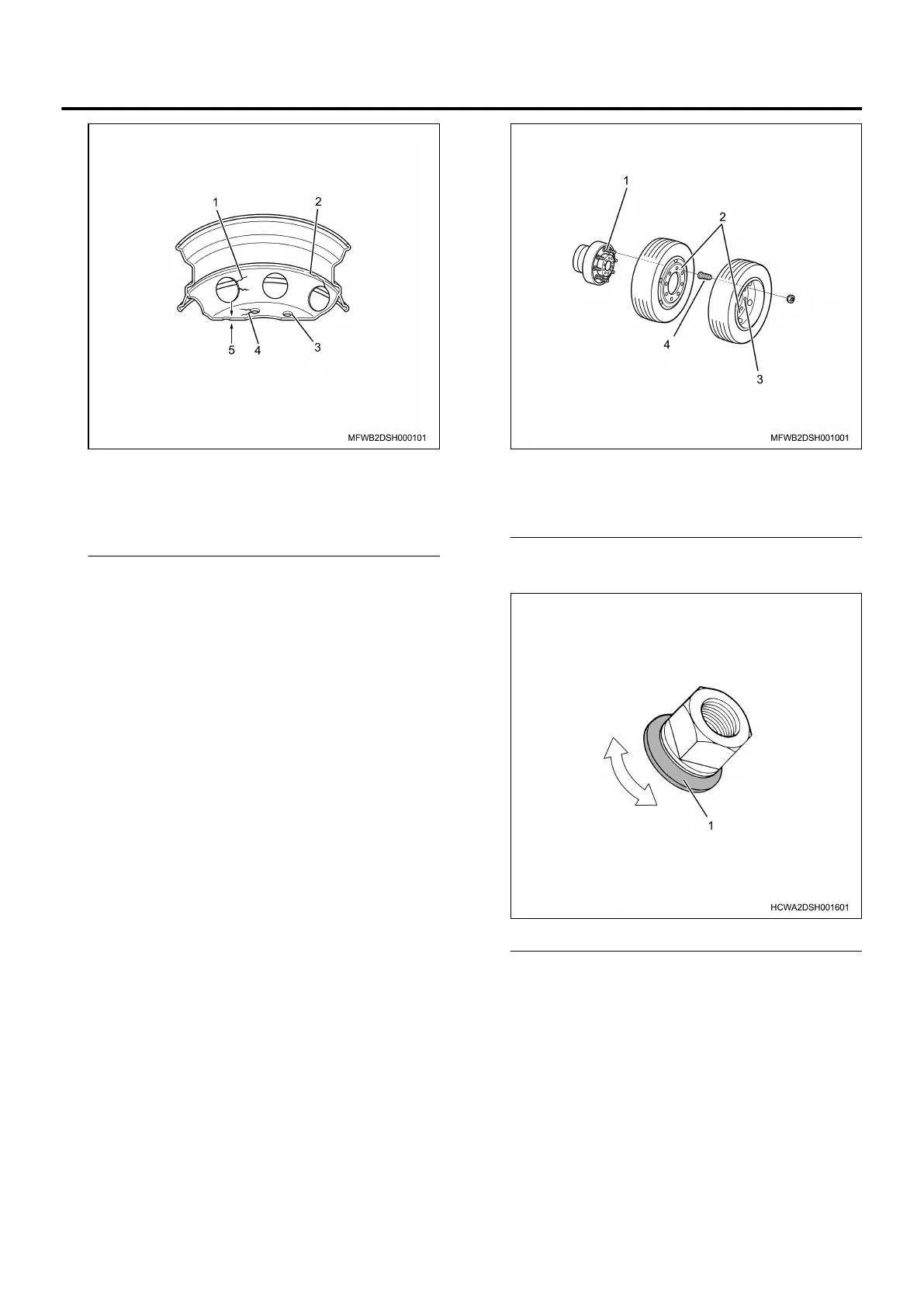

Inspect for cracks or damage.

Inspect the bolt to see if it is extended, or is significantly

rusty.

Inspect the screws for crushed sections, wear or gnawing.

1. Wheel bolt

2. Wheel mating surface, flat area

3. Wheel nut seating surface

4. Inner wheel nut

Check that the washer rotates smoothly. Replace the nut

if it does not rotate smoothly. (ISO 8/ISO 10 bolts)

1. Washer

Note:

・ Retightening and inspection of the wheel nuts

Inspect the wheel nut using a torque wrench to check

whether it is tightened at its specified torque.

Caution:

・ The tightening torque can drop because of

initial aging after the tires are replaced or

rotated. After running 50 to 100 km (31 to 62

mile), further tighten the wheel nuts at its

specified torque.

Functional Inspection (All models) 16C-23

Loading...

Loading...