HMPRO35 OPERATOR’S MANUAL

12 www.itmtools.com.au

TRADEMASTER

Magnetic Base Drilling Machines

Tools and Machinery

AIR

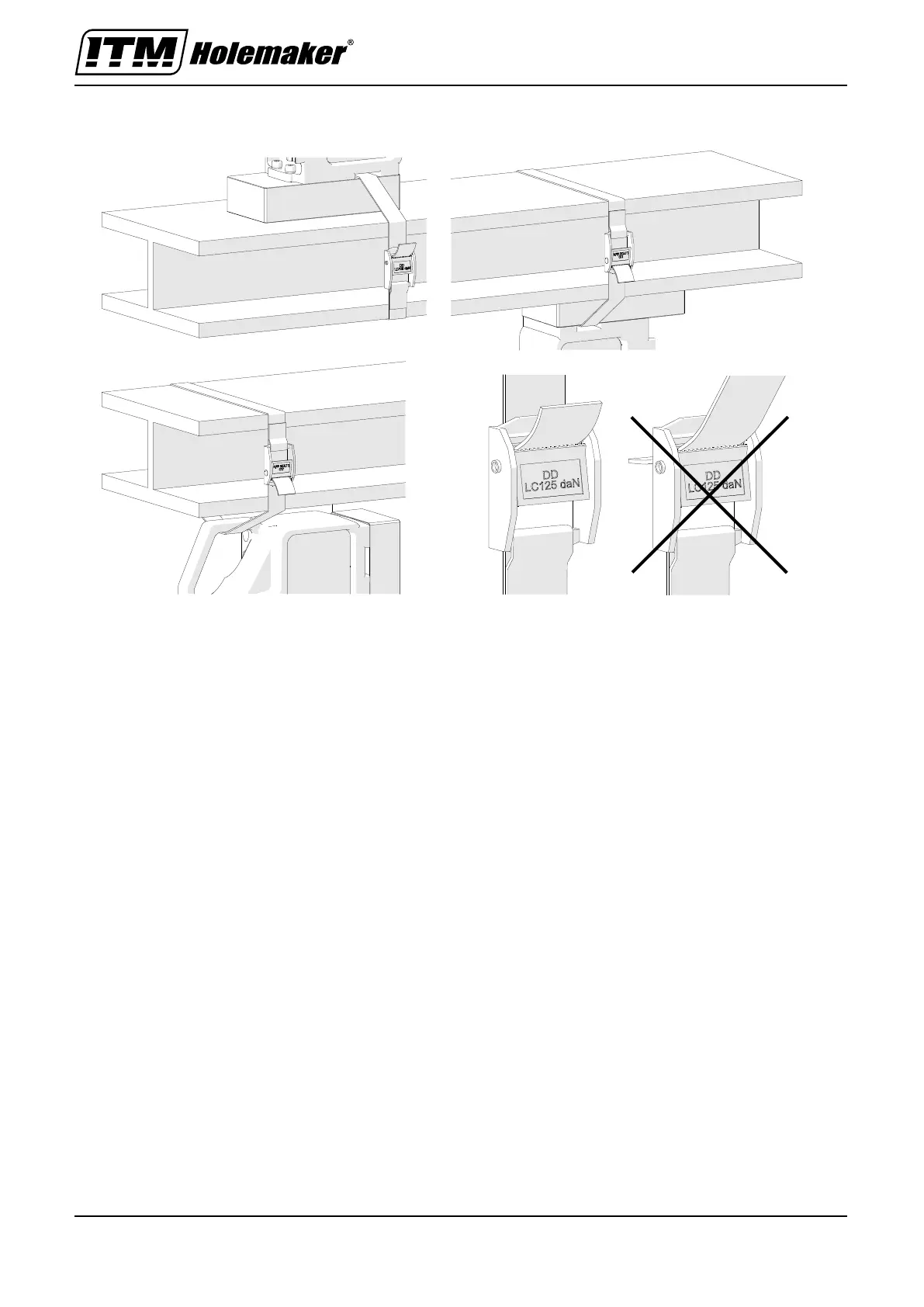

Fig. 5. Protecting the machine from falling by using the safety strap

Rotate the spoke handles to the left to place the tool above the workpiece.

When working with an annular cutter in the position from Fig. 5a, fill the cooling

system bottle with a cutting fluid. Do not use pure water as the cutting fluid. However,

using emulsions formed from mixing water and drilling oil is satisfactory. To check the

operation of the cooling system, slightly loosen the bottle cap, open the valve by

using the lever, and then rotate the spoke handles to the left to initially apply

pressure on the pilot pin. The coolant should fill the system and begin flowing from

the inside of the cutter.

Because the cooling system works by gravity, when working in inverted or

horizontal positions (Fig. 5b, 5c) use coolants under pressure or in the form of spray

or paste. Do not allow coolant to run into the motor.

Inverted drilling

INCORRECT

CORRECT

✓

a) b)

c)

d)

Vertical drilling

Horizontal

drilling

PRO 36

Fig. 5. Protecting the machine from falling by using the safety strap

Rotate the spoke handles to the left to place the tool above the workpiece.

When working with an annular cutter in the position from Fig. 5a, fill the cooling

system bottle with a cutting fluid. Do not use pure water as the cutting fluid. However,

using emulsions formed from mixing water and drilling oil is satisfactory. To check the

operation of the cooling system, slightly loosen the bottle cap, open the valve by

using the lever, and then rotate the spoke handles to the left to initially apply

pressure on the pilot pin. The coolant should fill the system and begin flowing from

the inside of the cutter.

Because the cooling system works by gravity, when working in inverted or

horizontal positions (Fig. 5b, 5c) use coolants under pressure or in the form of spray

or paste.

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

12

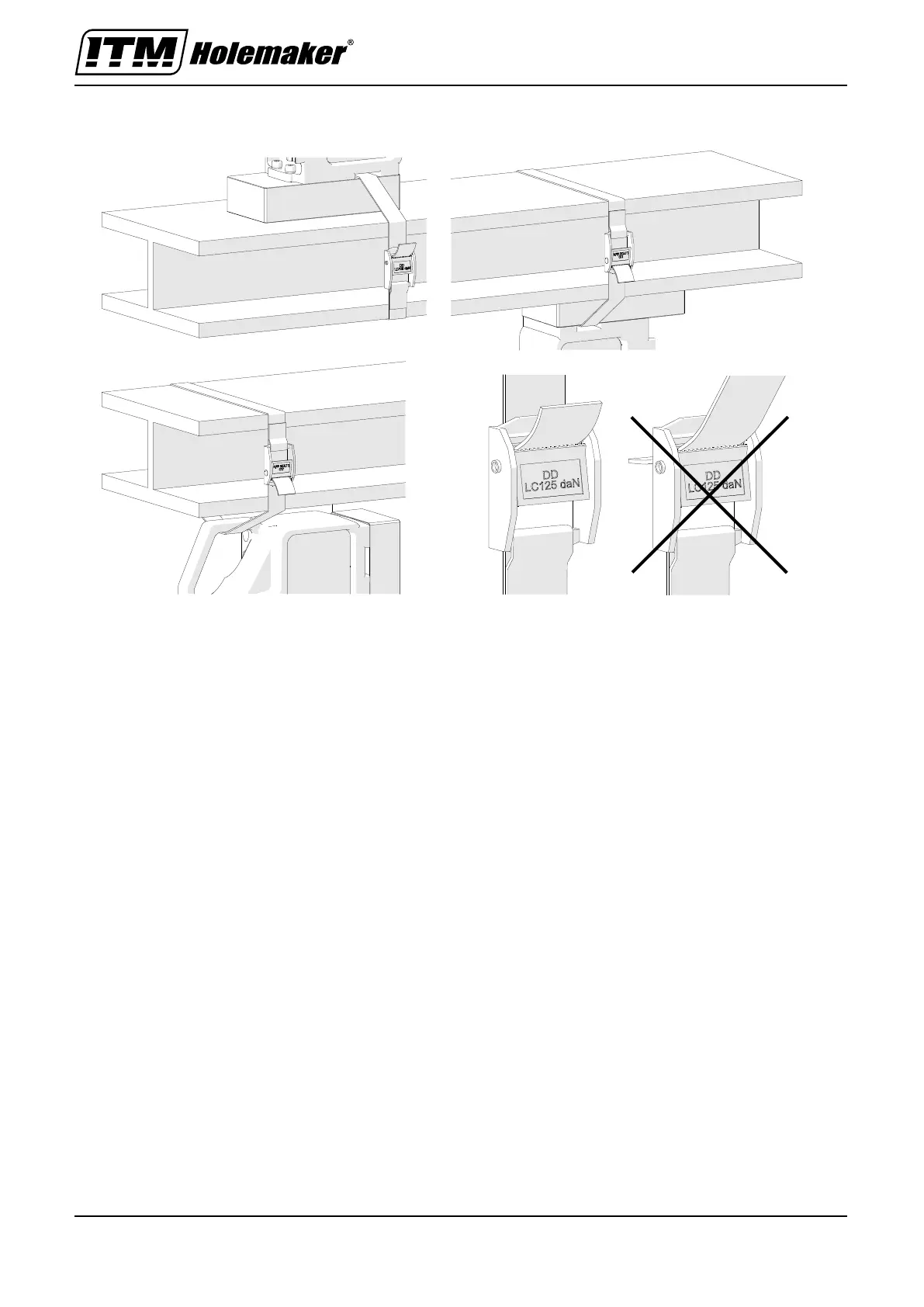

Inverted drilling

INCORRECT

CORRECT

✓

a) b)

c)

d)

Vertical drilling

Horizontal

drilling

PRO 36

Fig. 5. Protecting the machine from falling by using the safety strap

Rotate the spoke handles to the left to place the tool above the workpiece.

When working with an annular cutter in the position from Fig. 5a, fill the cooling

system bottle with a cutting fluid. Do not use pure water as the cutting fluid. However,

using

emulsions formed from mixing water and drilling oil is satisfactory. To check the

operation of the cooling system, slightly loosen the bottle cap, open the valve by

using the lever, and then rotate the spoke handles to the left to initially apply

pressure on the pilot pin. The coolant should fill the system and begin flowing from

the inside of the cutter.

Because the cooling system works by gravity, when working in inverted or

horizontal positions (Fig. 5b, 5c) use coolants under pressure or in the form of spray

or paste.

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

12

Inverted drilling

INCORRECT

CORRECT

✓

a) b)

c)

d)

Vertical drilling

Horizontal

drilling

Loading...

Loading...