HMPRO35 OPERATOR’S MANUAL

14 www.itmtools.com.au

TRADEMASTER

Magnetic Base Drilling Machines

Tools and Machinery

AIR

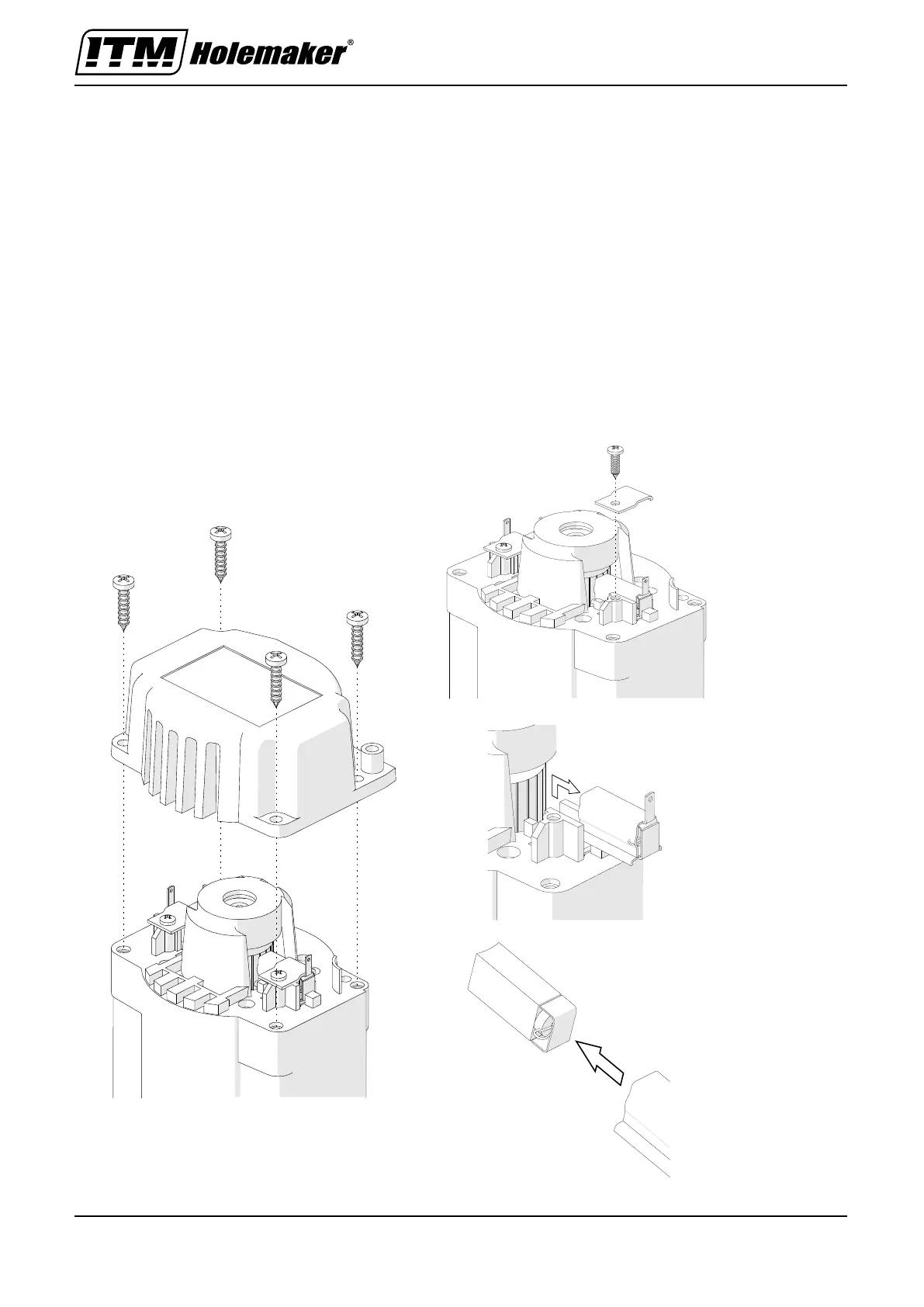

1.5. Replacing the motor brushes

ANY ELECTRICAL WORK INCLUDING CHANGING BRUSHES MUST BE DONE

BY A QUALIFIED AND LICENCED ELECTRICIAN

Check

the condition of the carbon brushes every 100 operation hours. To do this,

unplug the machine from the power source, and unscrew the cover (1, Fig. 6). Next,

unscrew the pressing plate (2), and then remove the brush holder (3) and the brush

(4). If the length of the brush is less than 5 mm, replace both brushes with new ones.

To install brushes, proceed in reverse order. After the replacement, run the motor

without load for 20 minutes.

Fig. 6. Replacing the brushes

1

2

3

4

2

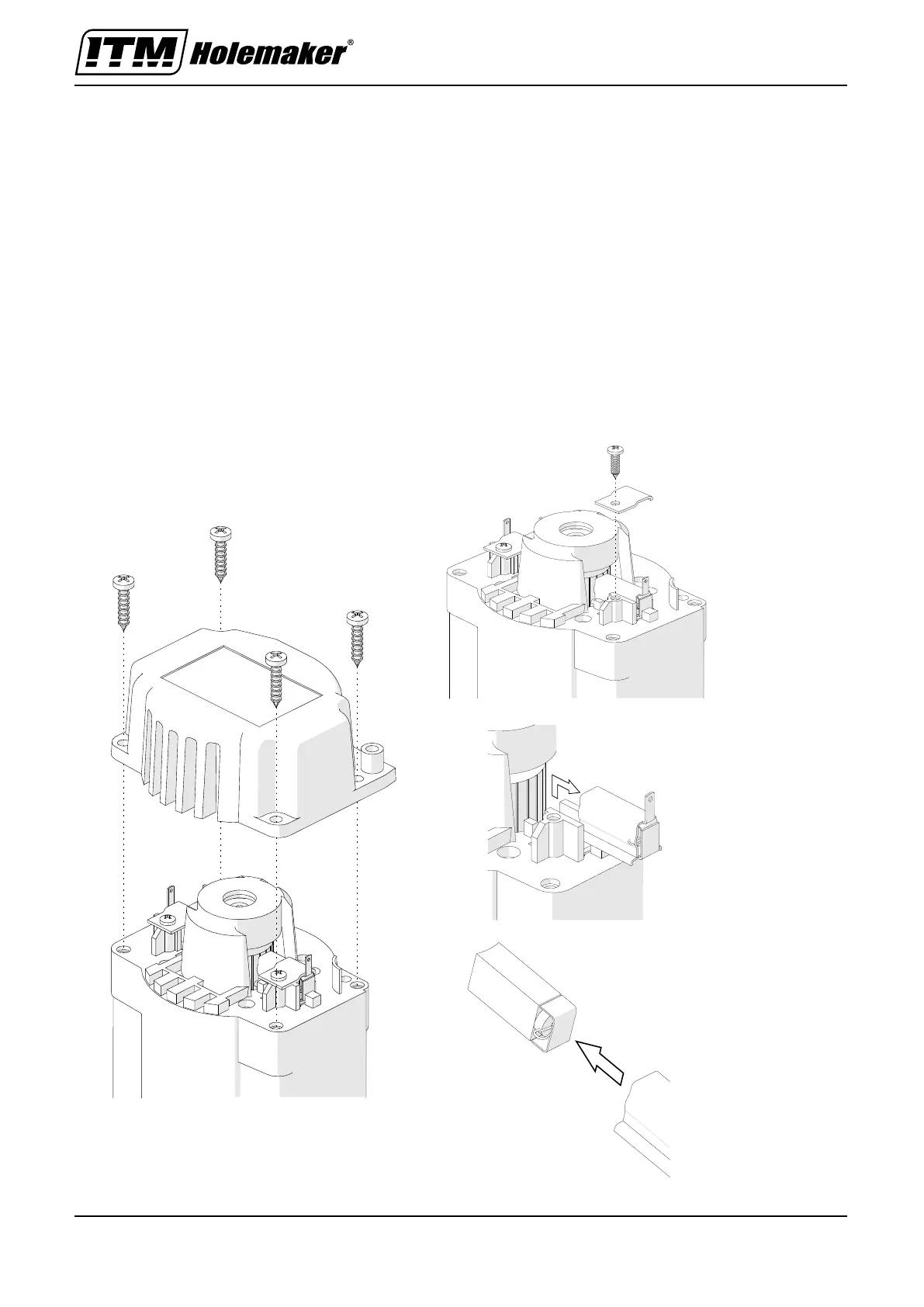

3.5 Replacing the motor brushes

1.5. Replacing the motor brushes

ANY ELECTRICAL WORK INCLUDING CHANGING BRUSHES MUST BE DONE

BY A QUALIFIED AND LICENCED ELECTRICIAN

Check

the

condition

of

the

carbon

brushes

every

100

operation

hours.

To

do

this,

unplug the machine from the power source, and unscrew the cover (1, Fig. 6). Next,

unscrew the pressing plate (2), and then remove the brush holder (3) and the brush

(4). If the length of the brush is less than 5 mm, replace both brushes with new ones.

To install brushes, proceed in reverse order. After the replacement, run the motor

without load for 20 minutes.

Fig. 6. Replacing the brushes

1

2

3

4

Loading...

Loading...