64

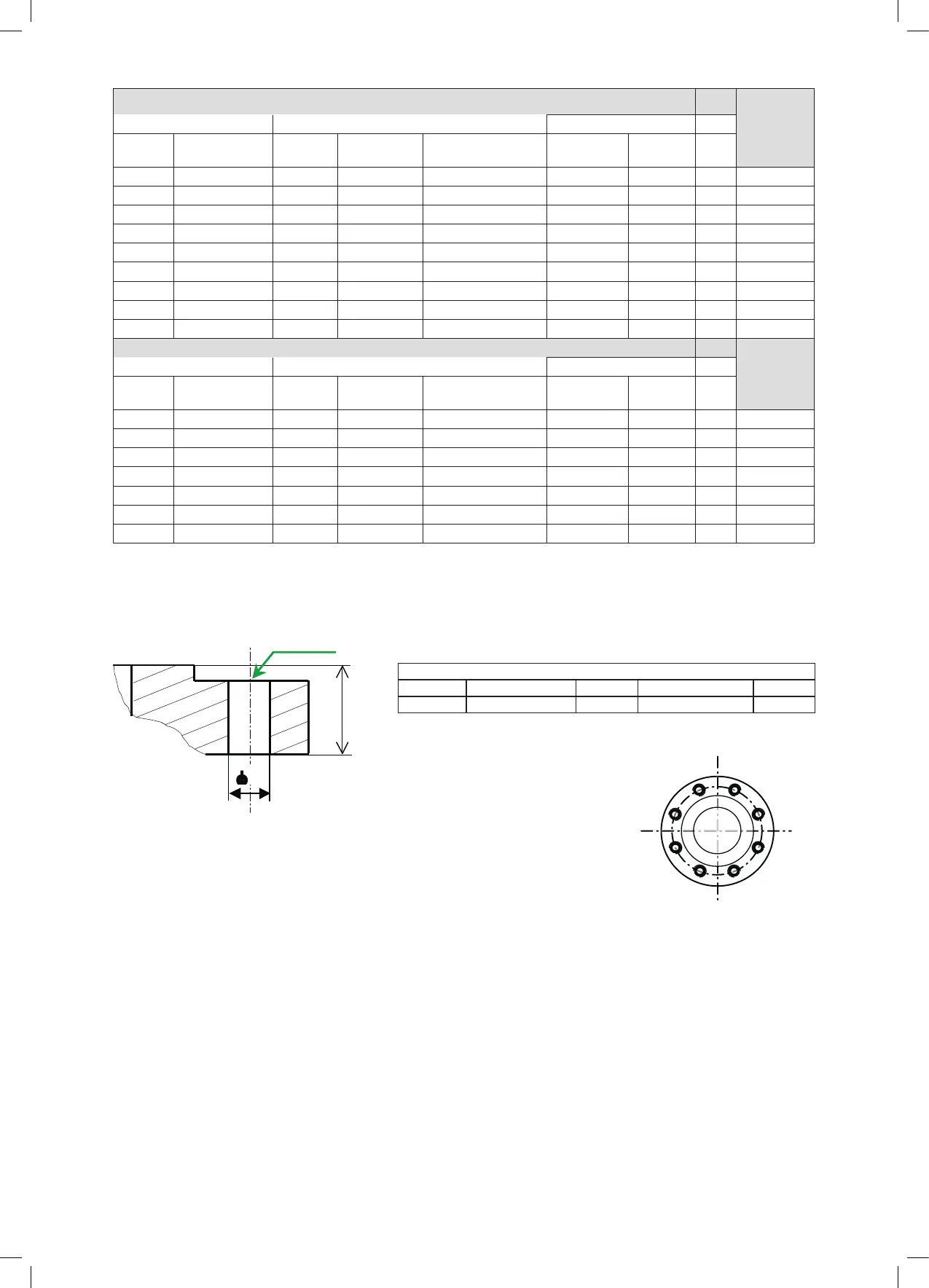

Flanges with holes with metric (M) screw thread

Maximum

torque value

(Nm)

L (mm)

DN Flanging

Number

of holes

Thread type Diameter “D” (mm) Alu

Ductile

iron

Steel

25 PN 10-16 4 M12 85 24 - 40

40 PN 10-16 4 M16 110 24 - - 100

50 PN 10-16 4 M16 125 24 24 28 100

50 PN 25 4 M16 125 - - 28 100

50 PN 40 4 M16 125 - - 28 100

50 Class 300 8 M16 127 - - 28 100

50 Class 600 8 M16 127 - - 28 100

80 PN 10-16 8 M16 160 24 24 - 100

100 PN 10-16 8 M16 180 24 24 - 100

Flanges with holes with inch (UNC) screw thread

Maximum

torque value

(Nm)

L (mm)

DN Flanging

Number

of holes

Thread type Diameter “D” (mm) Alu

Ductile

iron

Steel

25 150(125) 4 1/2” UNC-2B 79.4 24 - 40

40 150(125) 4 1/2” UNC-2B 98,6 24 - - 40

50 150(125) 4 5/8” UNC-2B 120,6 24 24 28 100

50 300 8 5/8” UNC-2B 127 - - 28 100

50 600 8 5/8” UNC-2B 127 - - 28 100

80 150(125) 4 5/8” UNC-2B 152,4 24 24 - 100

100 150(125) 8 5/8” UNC-2B 190,5 24 24 - 100

Flanged meters with holes NOT threaded

Meters DN150 G250 to G650 (S3-Flow) are available with flanged connections. Holes in the flanges

are not threaded.

PN 10-16, Class 150

DN Number of holes ø f

Diameter “D”

(mm)

T

150 8 22,4 241 26

Notes

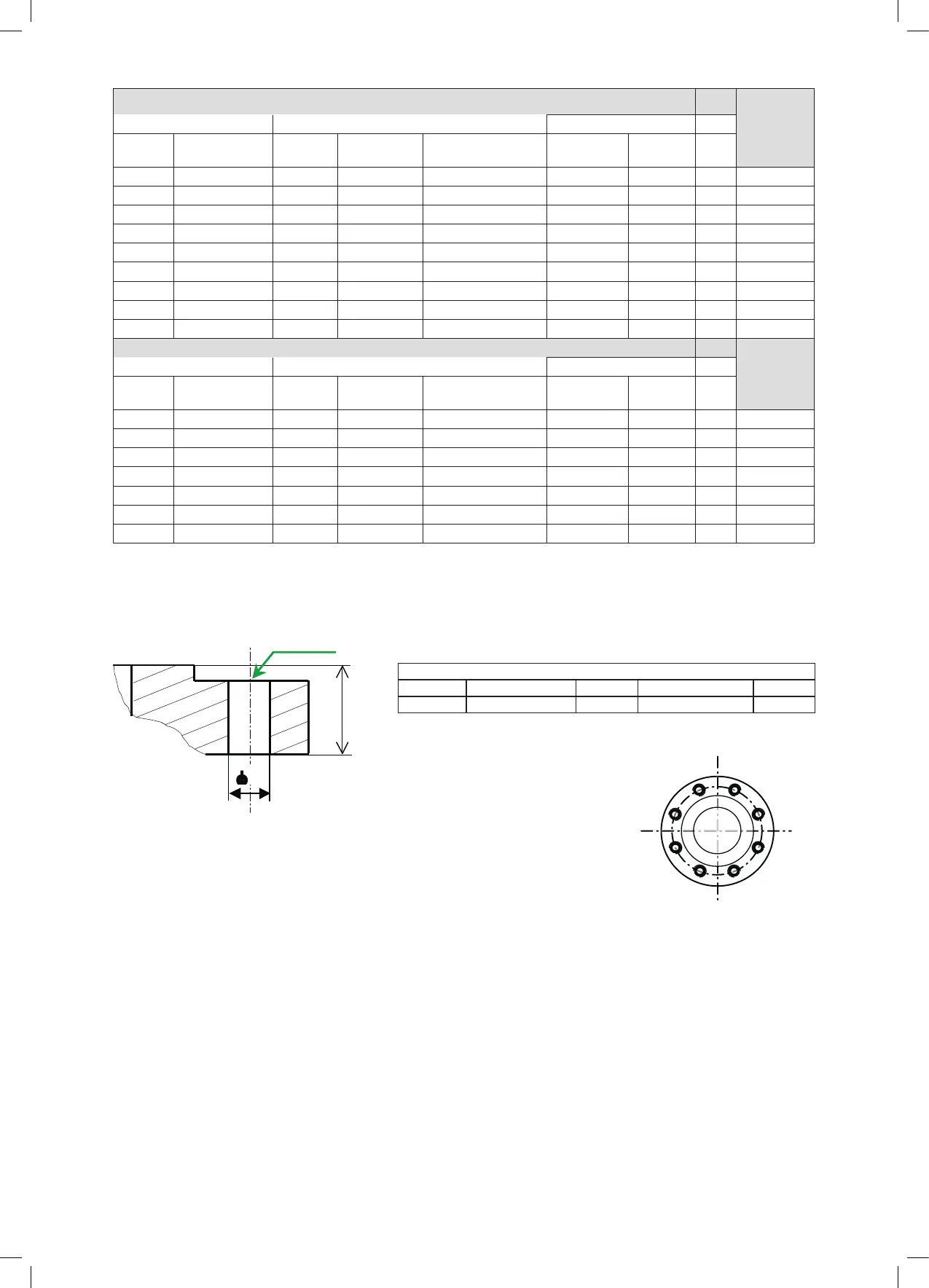

• Install all the screws and tight those smoothly

before applying the tightening torque.

• Tight the screws in opposite pairs according the order of figure 1.

Annex 2: Commercial reference / Références commerciales / Kommerzielle Referenzen / Referenze commerciali / Marcas de

Lubrificantes / Toepasbare oliesoorten / Ticari referanslar / Referências Comerciais / Obchodní reference

– Shell Tellus T15

– Oest V3136L (lubricant delivered with each meter, commercial name: Maxilub VG10)

Face of the flange

1

6

7

8

2

5

4

3

Figure 1

Loading...

Loading...