Copyright 2017

, Itron, Alle Rechte vorbehalten

, Dokument:

Instruction_manual_G10 to G100__2017

-02-27.docx

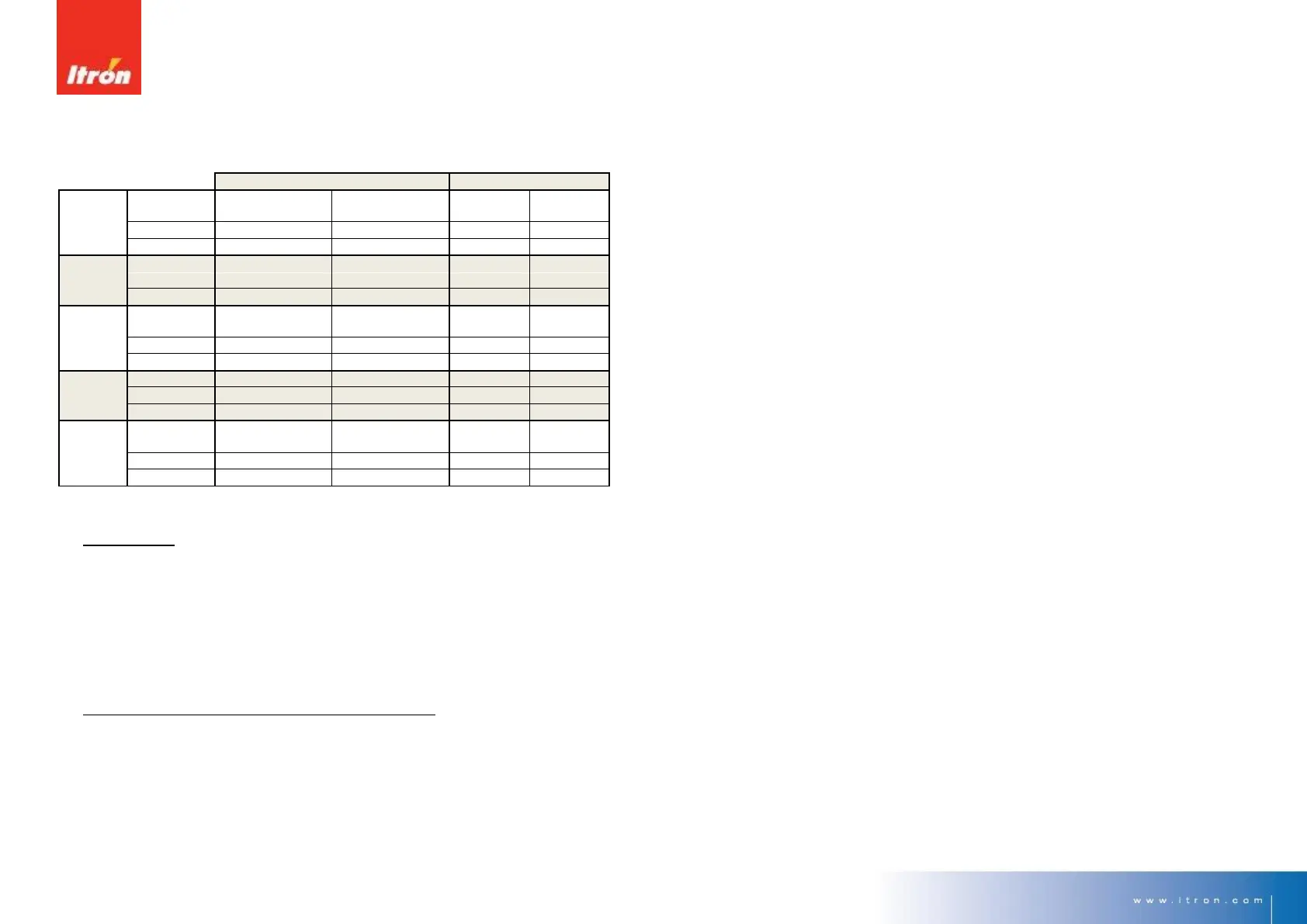

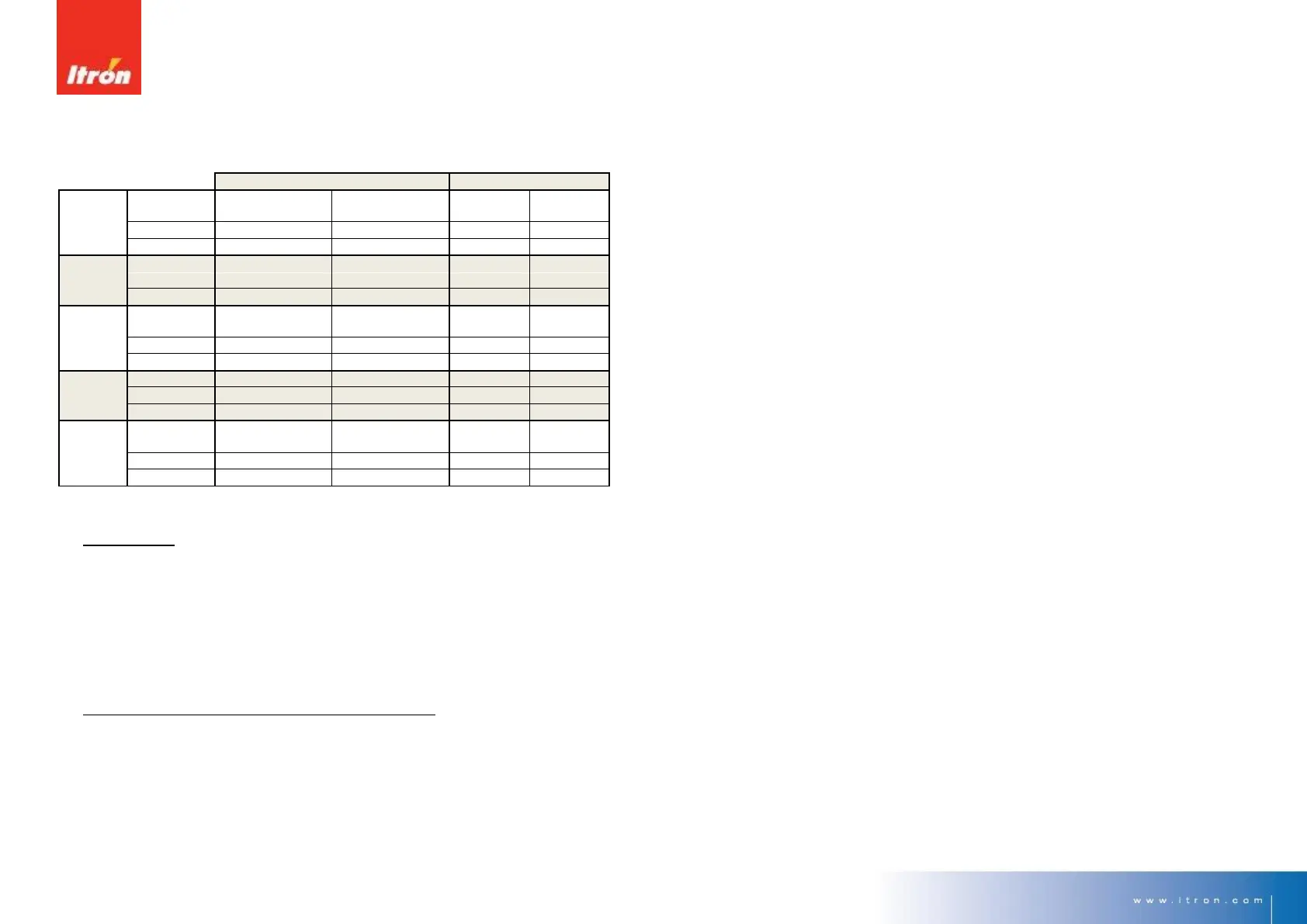

For the connecting nut of the studs, the following maximum tightening torque apply for

hard gaskets:

For other gasket types please refer to the affected standards. The screws of the flange

connections have to be adequate-sized and to be tightened crosswise.

5. Commissioning:

Caution is necessary when commissioning the meter after installation. The max.

operating pressure and max. flow rate are marked on the name plate. Never exceed

these values.

Open the outlet valve (if installed) completely. Then open the inlet valve to pressurize

the meter very slowly and avoid pressure pulses. Bring the valve to a fully opened

position.

Finally check the tightness of all connections.

6. Maintenance – Diaphragm gas meters are maintenance-free:

When the meter is commissioned properly and the operating conditions stay normal, no

additional maintenance is necessary during the life of the meter.

Dust and dirt should be removed with solvent and alcohol-free products. Please note

that the meter has to be protected against unusual mechanical, thermal and chemical

damages.

Loading...

Loading...