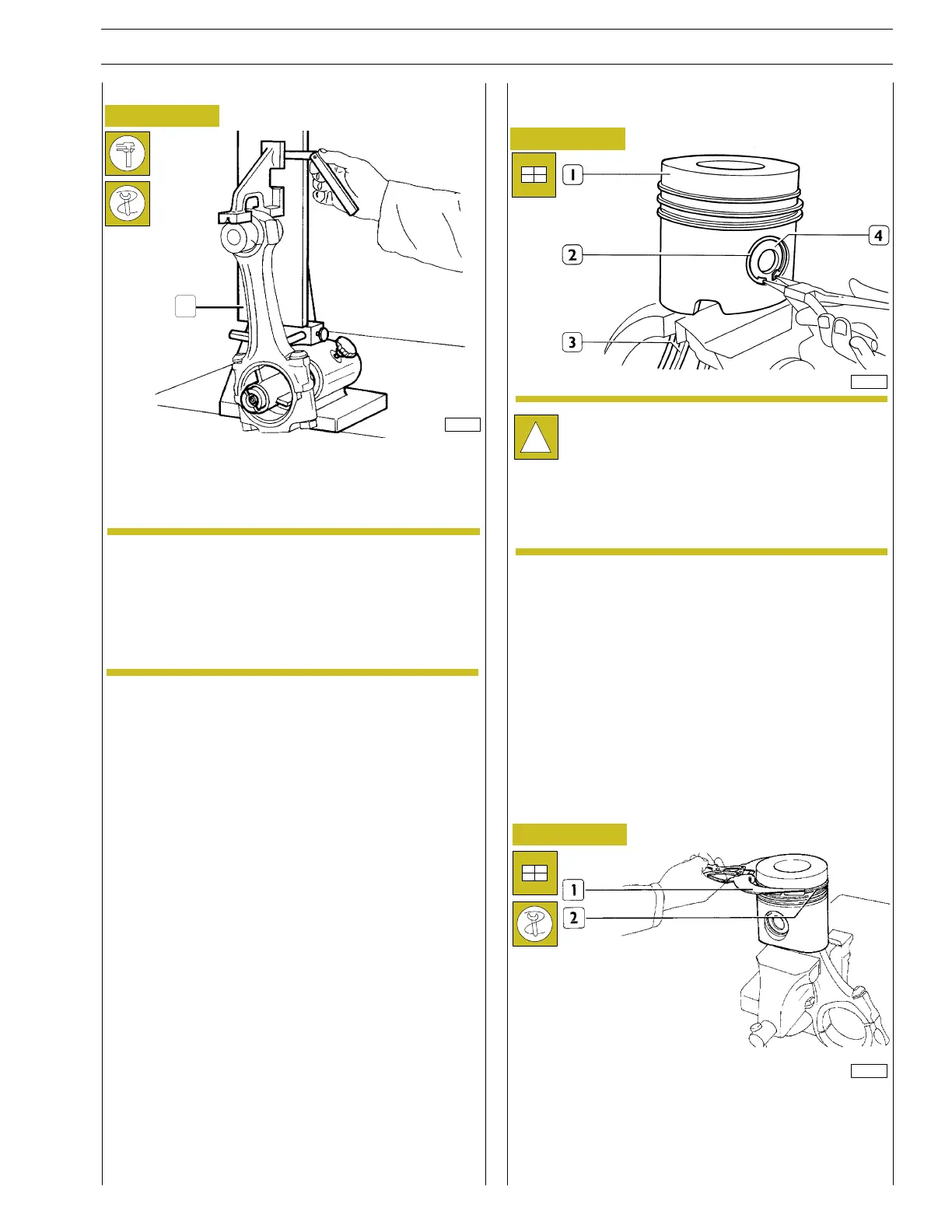

Figure 65

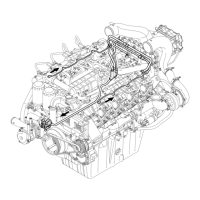

Figure 66

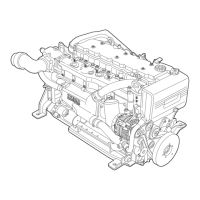

Figure 67

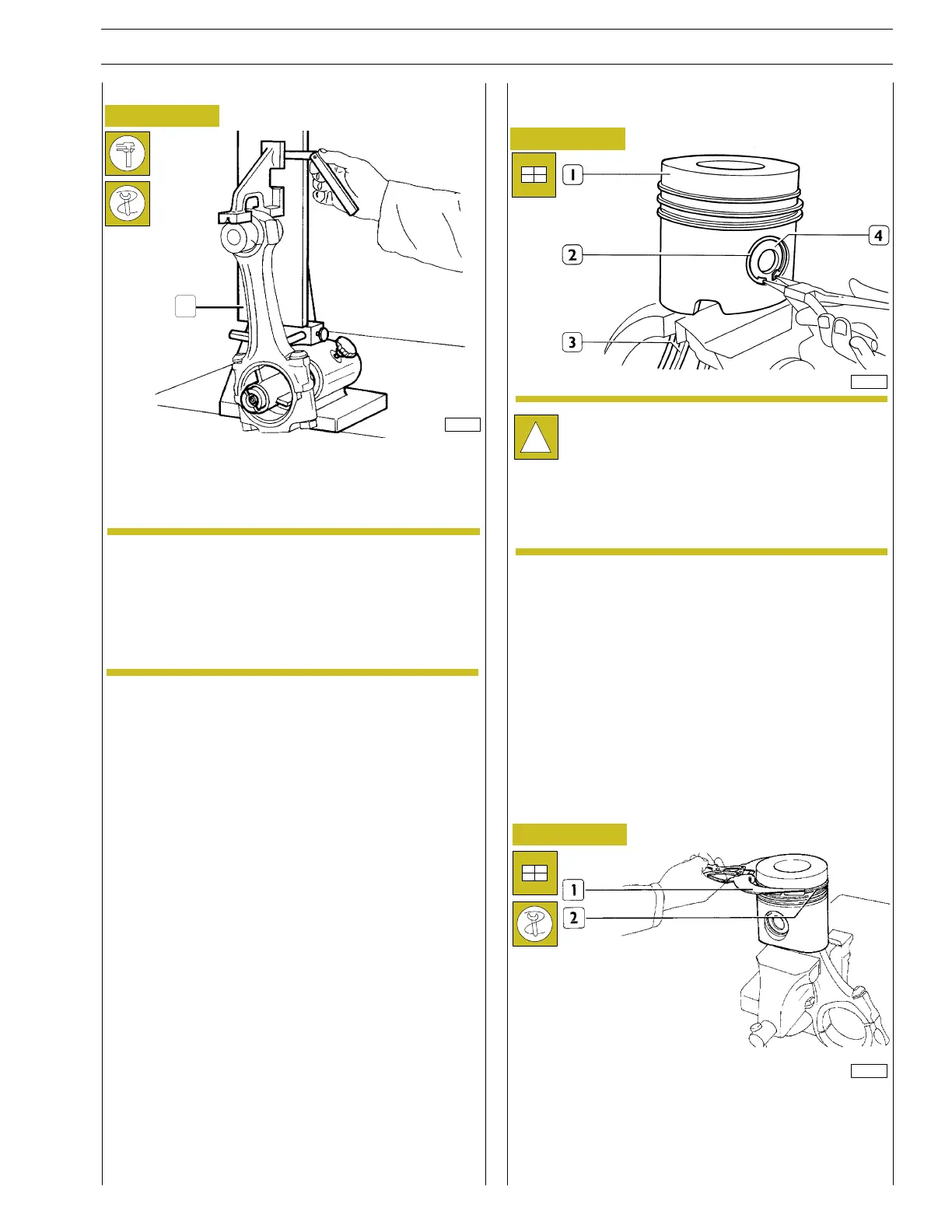

Use apparatus 99395363 (1) to check parallelism of the rod

arms. T he maximum permitted tollerance is ± 0.05 mm,

measured at 125 mm from the longitudinal axis of the rod. If

a misalignment exceeding the permitted tolerance is encoun-

tered, replace the rod.

- Position the pi ston (1) on the rod (3), insert the pin (4)

and secure it with the piston rings (2).

- Insert the piston rings (2) on the piston using pliers

99360183 (1).

The body and cap of every connecting rod is marked

with a number indicating the part with which is to be

mated. In addition, the number of the cylinder where

the rod should be installed may be stamped on it.

Therefore, when replacing the rod, it is necessary to

mark the new rod with the same number as the rod

whitch is being replaced.

!

Fitting the piston rings

1

Check of connecting rod alignment Fitting the connecting rod—piston assembly

Connecting rod—piston mating

The connecting rod — piston coupling must be made

taking account that, on fitting the assembly in the cylin-

der block, the wording ”TAPPET SIDE” (stamped on

the crown of the piston) must be fac ing the tappet

side of the engine and the numbering of the connect-

ing rods must be facing the corresponding numbering

stamped on the cylinder block.

16557

37715

16817

NOTE

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS 31

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...