FAA Approved Installation Manual for the Report No 908

EDM-900 and EDM-930 Page 13 of 56 Rev I

Primary Engine Data Management System Date 1-18-2013

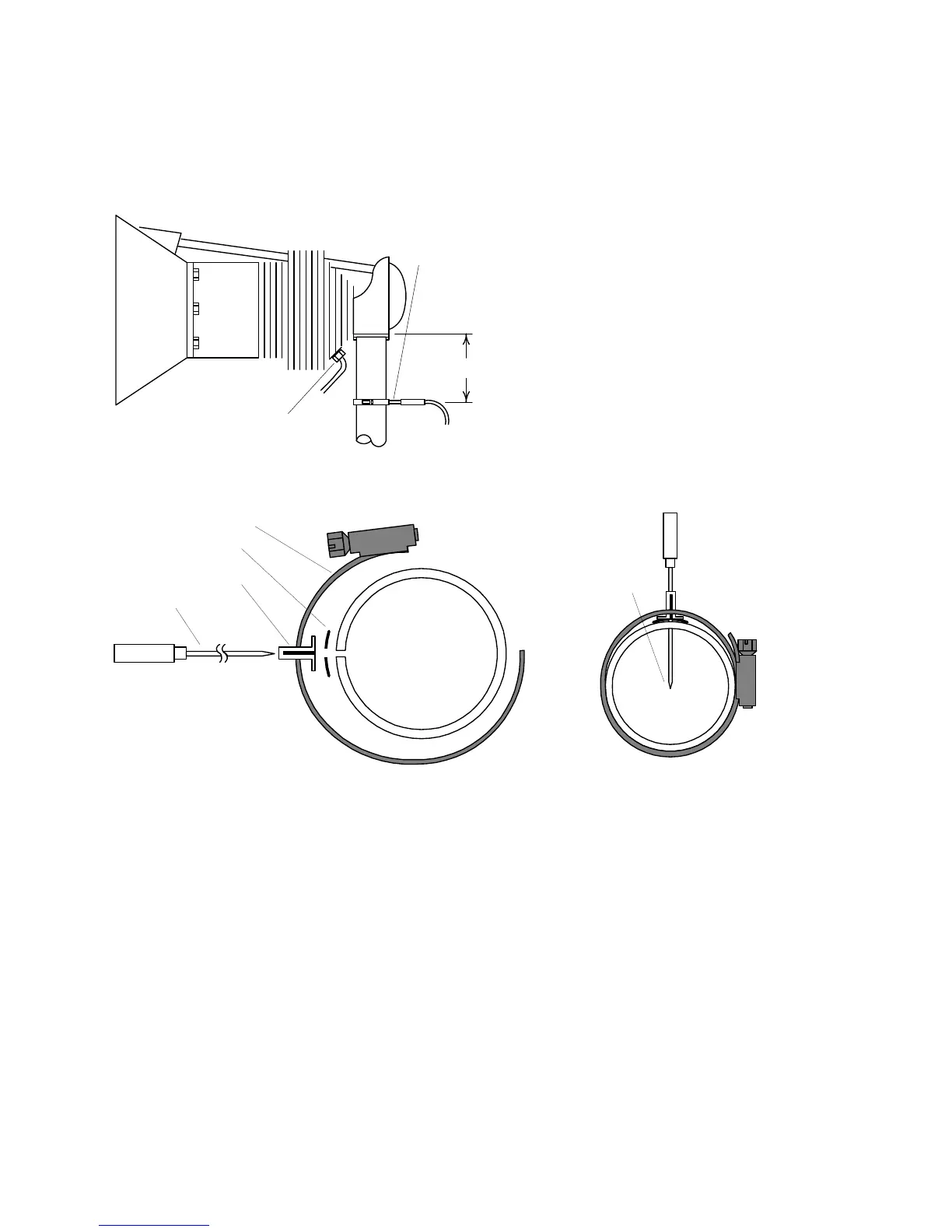

The Model M-111 Probe will fit any engines where

the existing holes in the exhaust stack are 1/8" to

1/4" in diameter. If no hole exists, it will require the

drilling of a 1/8" diameter hole and ream to fit. It is

important that each probe be mounted the same

distance from its exhaust stack flange. A nominal

distance of 2 to 4 inches from the exhaust flange is

recommended. If the recommended distance is

impractical because of obstructions, slip joints or

bends in the exhaust system then position the

probes a uniform distance from the flange as space

permits. Do not mount probes in slip joints. Be

certain to locate all holes BEFORE drilling to

ensure that nothing interferes with the probe,

clamp, screw or wire. Careful matching of probe

position will provide best temperature readings.

Insert the probe in the exhaust or previously drilled hole so that the tip of the probe is in the center of the exhaust

stream. Tighten the stainless steel clamp to a torque of 45 in/Lbs. Cut off the excess strap close to the screw.

Position probe

in approximate

center of

exhaust

Probe

Clamp

Thimble

note orientation of

slot

Seal Washer

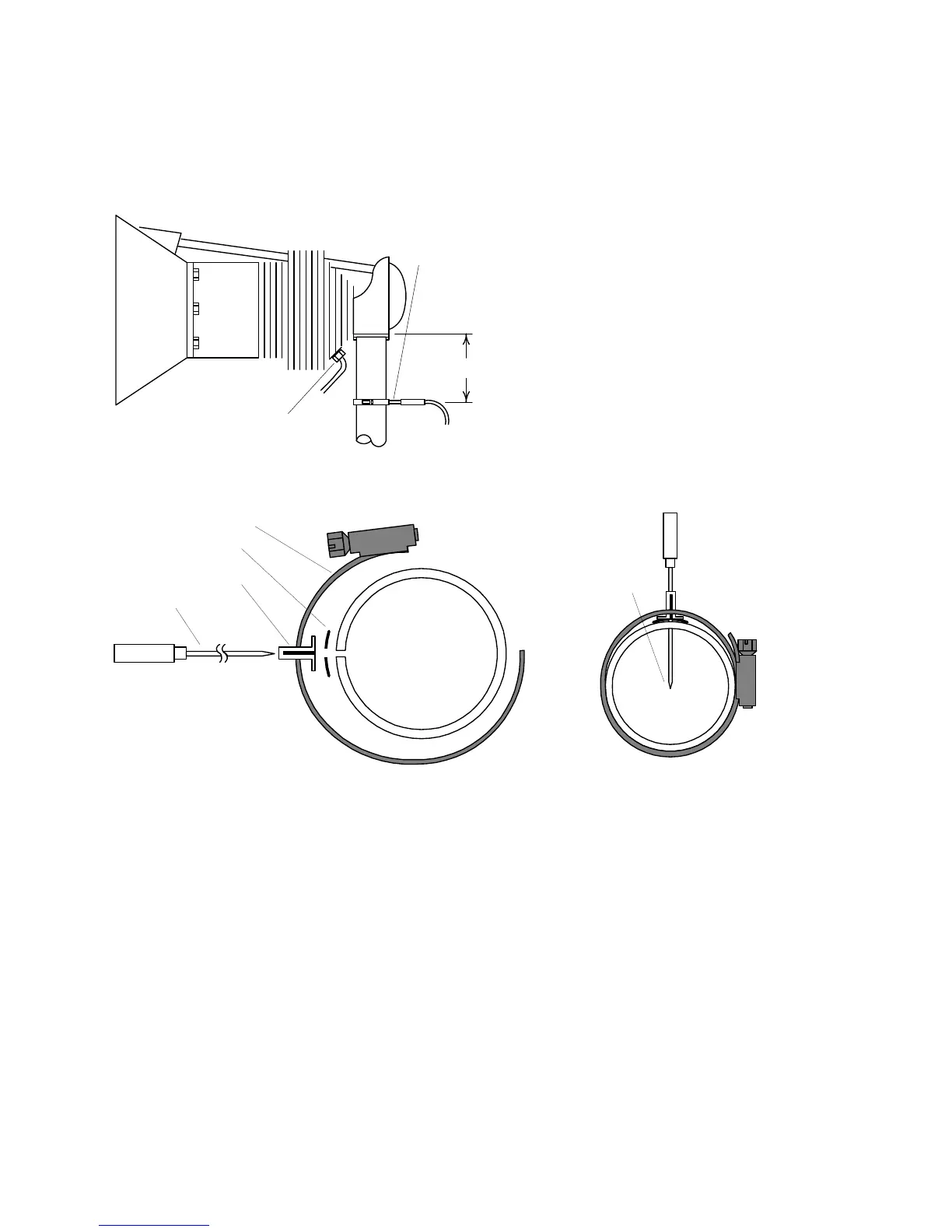

12. RADIAL Engine EGT

Radial engine exhaust, require a larger EGT clamp (supplied) to fit the 2.5 inch exhaust pipe. The EGT probe is installed in the

same fashion as a Lycoming or Continental engine and should be placed between the exhaust pipe flange and the accumulator

at a distance of 2 to 3 inches from the engine exhaust flange. Refer to the engine manufactures recommended location. Do not

route the EGT/CHT harness in with the ignition harness. Do not extend the yellow thermocouple leads with copper wire.

13. Turbine Inlet Temperature (TIT) Probe Installation (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 16 and the red wire into pin

17. The standard TIT probe PN M111-T with a #48 clamp is placed in the exhaust stack accumulator to a maximum

depth of 1/2 inch and approximately 4 inches from the turbine inlet if possible, on the waste-gate side of the turbine.

13.1 TIT for second Turbine Inlet Temperature

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 18 and the red wire into pin

19. The standard JPI TIT probe P/N M-111-T with a special clamp is placed in the exhaust stack accumulator to a

maximum depth of 1/2 inch and approximately four inches from the Turbine inlet if possible, on the waste gate side

of the turbine.

2" to 4"

EGT probe

Drill no. 40

pilot hole,

then no. 30

hole.

CHT probe

exhaust stack

Loading...

Loading...