INSTRUCTION MANUAL CODE 80416 REV D 12/2023 Page: 52

J.P. SELECTA s.a.u. Autovía A-2 Km 585.1 Abrera 08630 (Barcelona) España Tel 34 937 700 877 Fax 34 937 702 362

e-mail: selecta@jpselecta.es - website: http://www.grupo-selecta.com

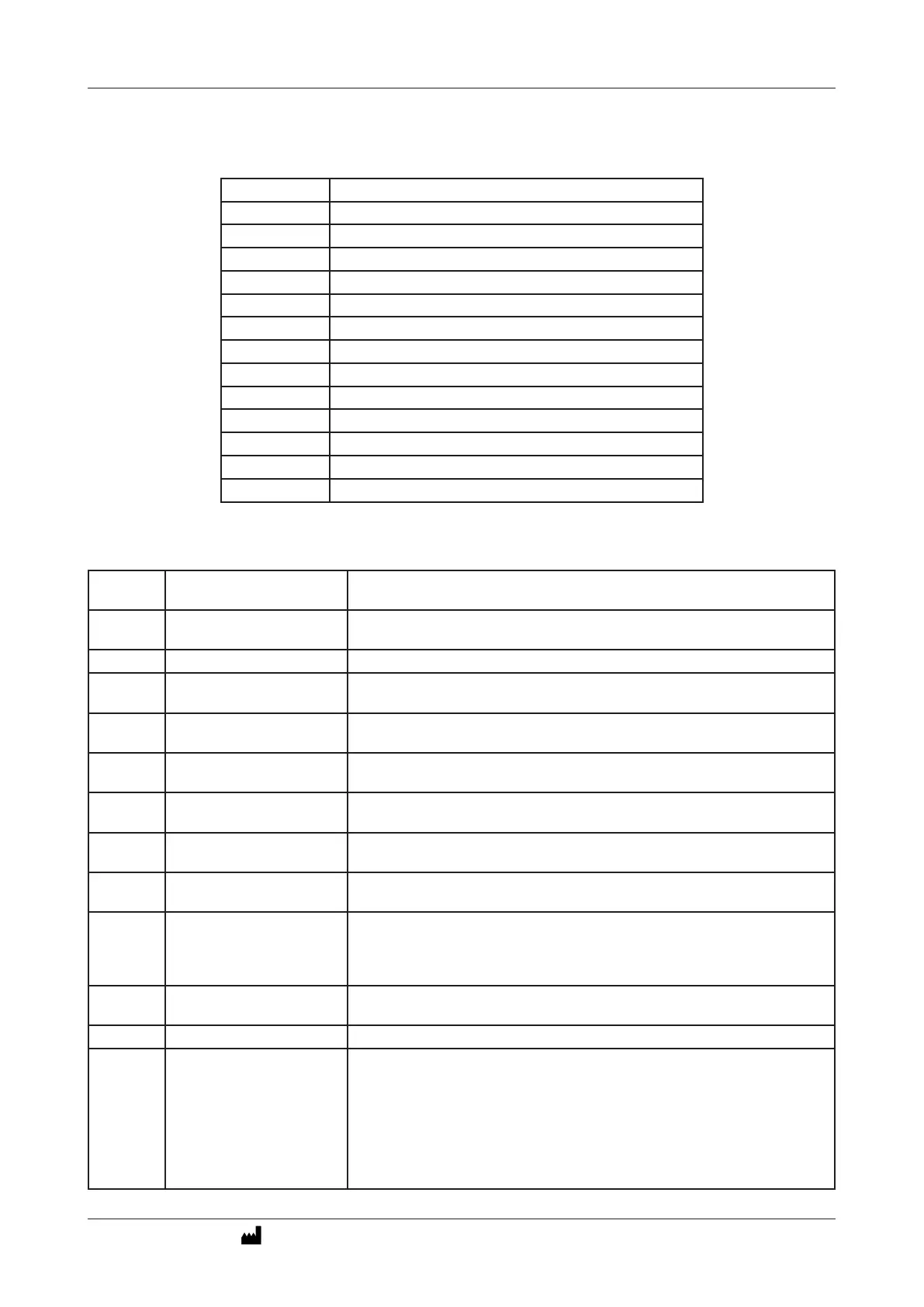

8.7 Items to inspect during annual maintenance

1 Exterior The exterior of sterilizer should be tidy and mustn’t have the disgurements,

such as deection, hollowness, collision, nick, sharp edge, and so on.

2 Cover plate The cover plate should be assured to disassemble easily in order to repair

the equipment.

3 Digit and letter The digit and letter in screen should be legible.

4 Electroplate components The Electroplate should accord with YYOO76-1992 class 2, which for the

request of aspect.

5 Printer components The Printer components should accord with YY1055-1999 the class 2 which

for the request of aspect.

6 Door safe lock On the normal condition, if the sterilizer door hasn’t been locked tightly, the

program can not start.

7 Chamber Pressure The sterilizer should ensure that the door can’t be opened when chamber

pressure is greater than 0.27Mpa.

8 Safety Valve The sterilizer must install a safety valve, safety valve opening pressure

0.27Mpa ± 0.01Mpa, and automatically open when reaching the set value.

9 Sterilizing Program Sterilizer should have the pre-established program about 121ºC and 135ºC,

dressing and instruments.

10 Controlling system The control system in sterilizer should limit the steam which in the chamber

be controlled at the highest average temperature in ±3ºC of pre-establish

station. And ensure the temperature value accords with the pressure control-

ling value.

11 Timing control Able to timing control of the sterilization and drying, and the error should

not be greater than 10% of the preset value.

12 Button and Switch Buttons and switches should be exible and reliable on the sterilizer.

13 Indicator and display The indicators and displays of sterilizer should show the states of every

sterilizing procedure exactly. Under the normal situation, sterilizer should

indicate:

a) Chamber temperature

b) Chamber pressure

c) Sterilizer working state

d) Water level state

e) State of door

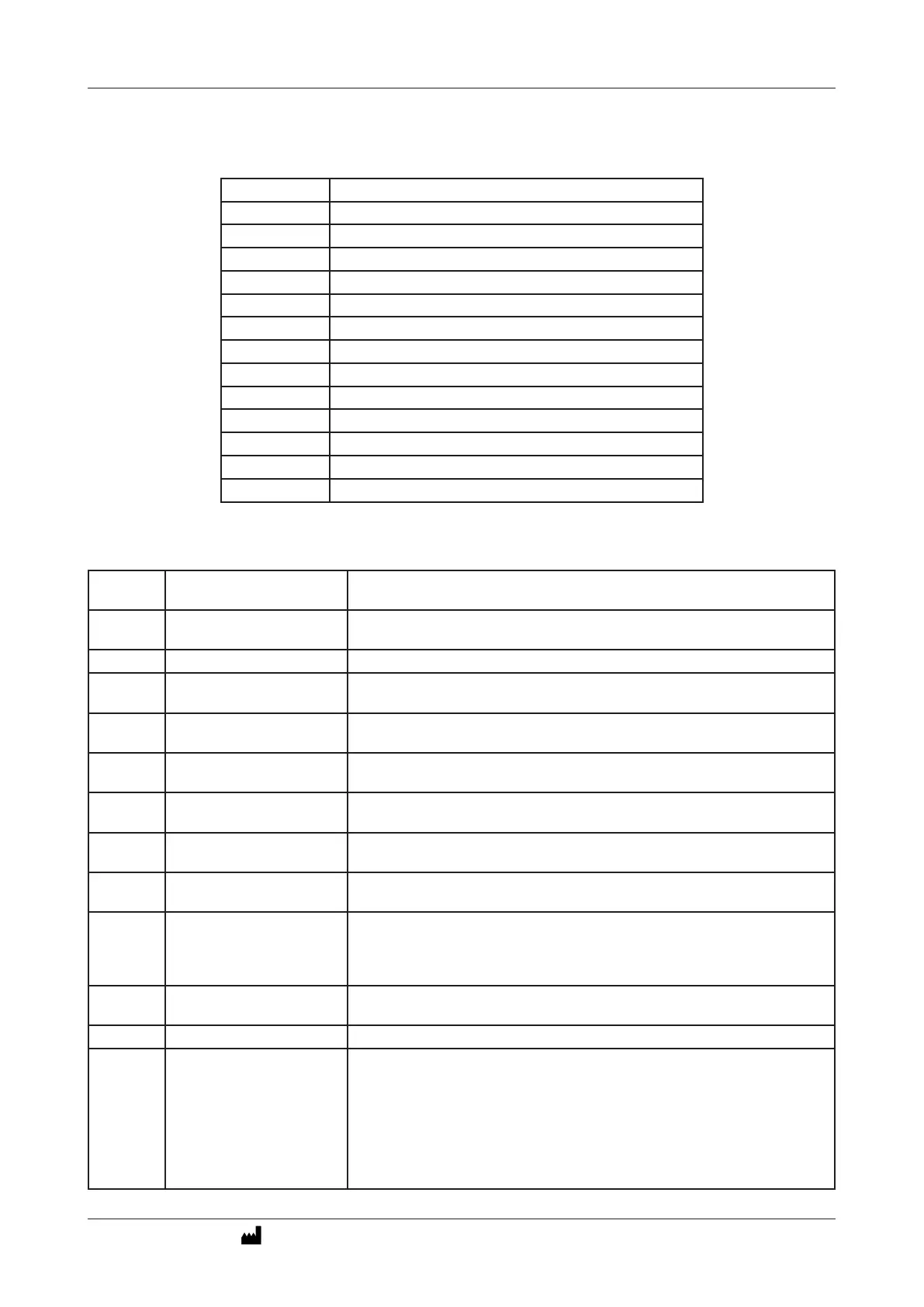

8.6 List of alarm codes

Error Alarm List

CODE No. Error Information

Abnormal exit

01 Temperature sensor fault (steam generator)

02 Temperature sensor fault (out chamber)

03 Temperature sensor fault (inner chamber)

04 Sterilization fail

05 Pressure not exhausted

06 Door open in the cycle

07 Operation over time

08 Over pressure

09 Over temperature

10 Pressure and temperature do not match

11 Vacuum process fail

98 Power fail

Loading...

Loading...