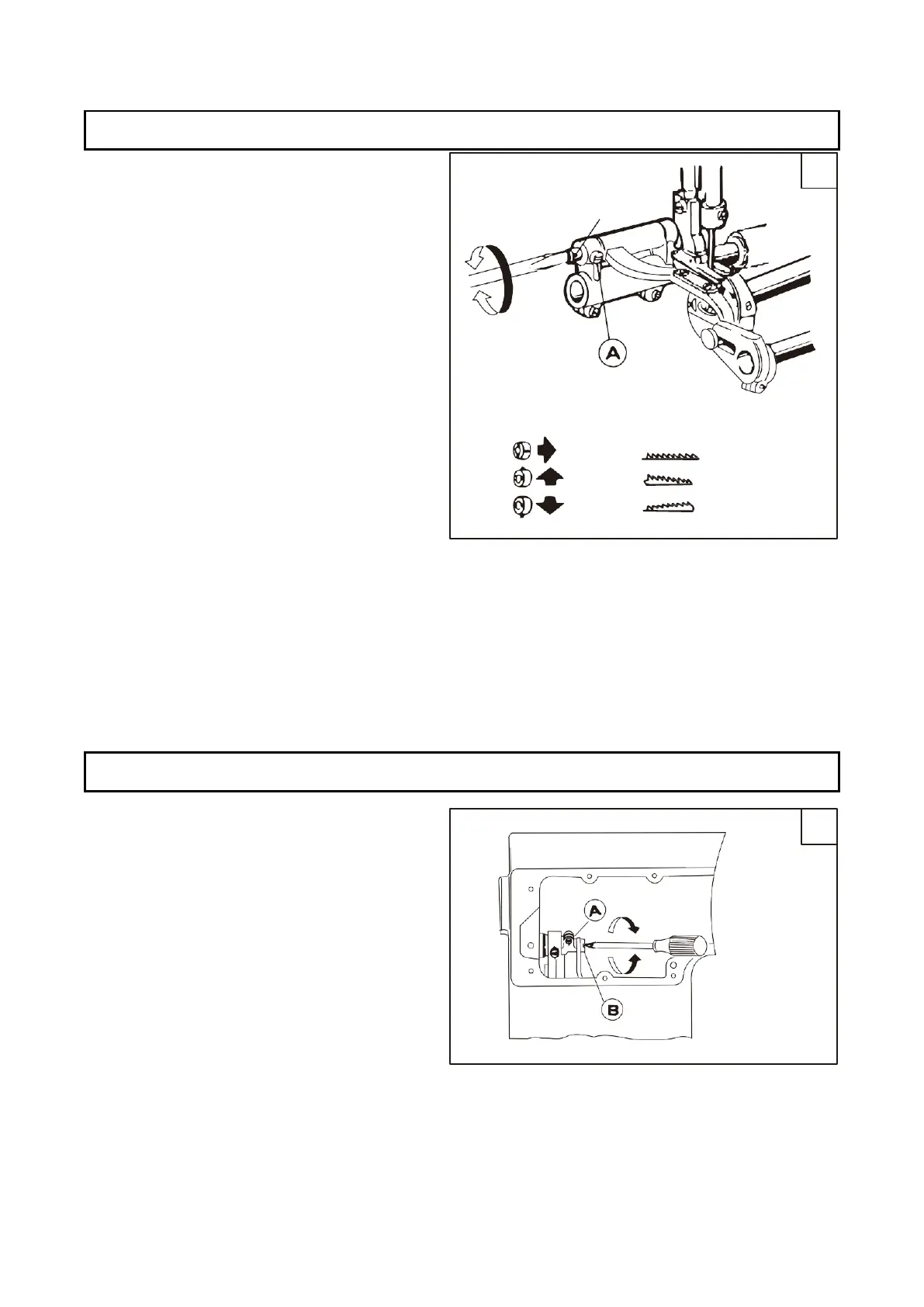

送布牙一般是水平位置。高于针板平面0.8~

1.2毫米。当缝制条件需倾斜时应调节。

a.旋松牙架曲柄轴螺钉(A)。

b.用螺钉起子压在牙架曲柄偏心轴的槽里,使

偏心轴左右转动。

c.最后将(A)螺钉拧紧。

送布牙前面高时,可防止布料起缩,不容易

出现空针。

送布牙前面低时,可防止布料跑偏,底线不

易断

The feed dog is generally horizontal. 0.8~

1.2mm above the plane of the needle board. It

should be adjusted when the sewing conditions need

to be inclined.

a. Loosen the crankshaft screw (A) of the tooth

frame.

b. Use a screwdriver to press in the groove of the eccentric shaft of the bracket crank to make the eccentric

shaft rotate left and right.

c. Finally tighten the (A) screw.

When the front of the feed dog is high, the fabric can be prevented from shrinking and shrinking, and empty

stitches are not easy to appear.

When the front of the feed dog is low, the fabric can be prevented from running off and the bottom thread is

not easy to break.

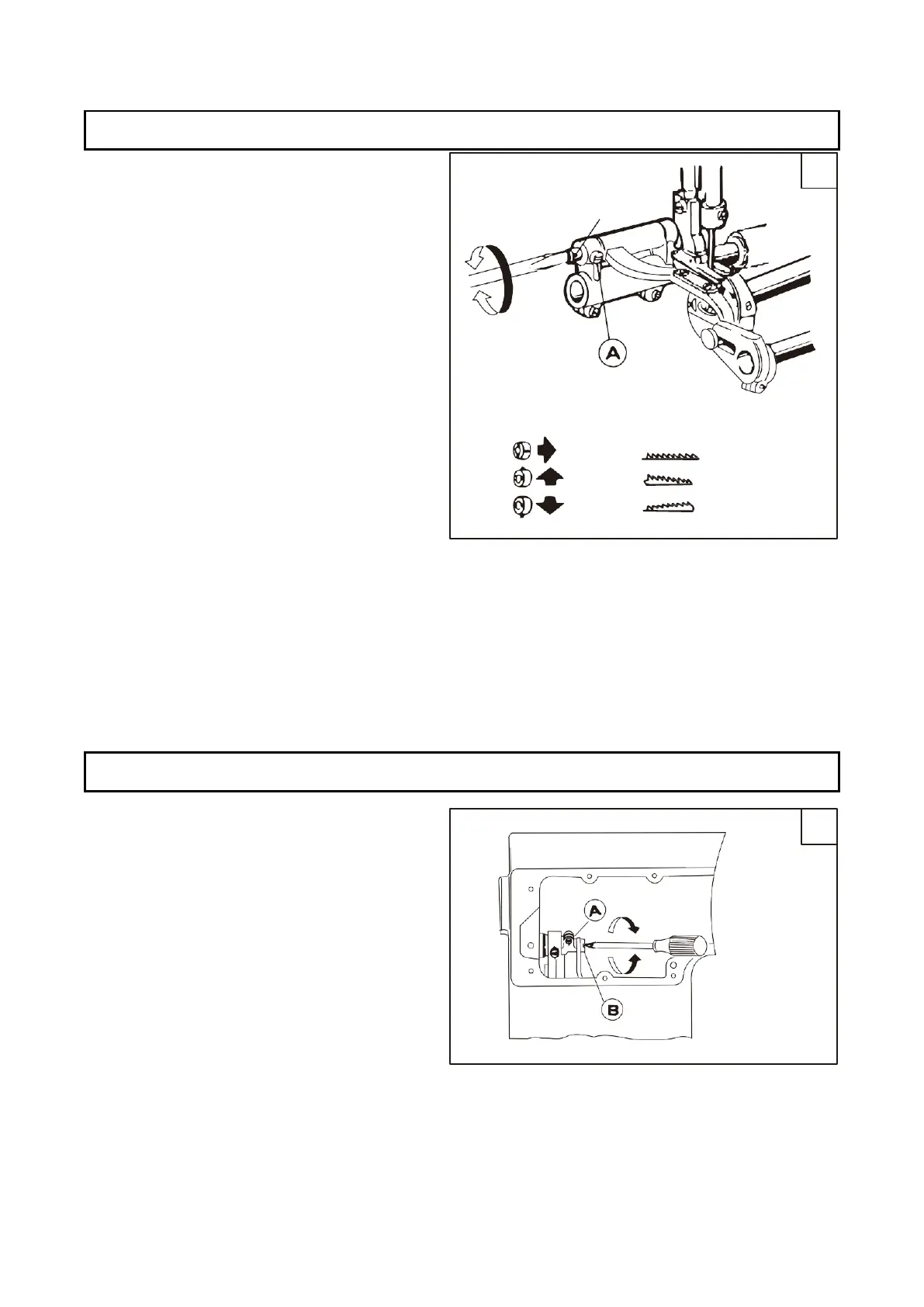

旋松螺钉(A)转动针距调节凸轮(B)

顺时针转:——顺缝针距变大。

倒缝针距变小。

逆时针距:——顺缝针距变大。

倒缝针距变小。

Loosen screw (A), and turn stitch length

adjusting cam (B).

Turn clockwise: forward sewing, stitch length

enlarged; reverse sewing, stitch length shorten.

Turn counter-clockwise: forward sewing stitch length

shorten; reverse sewing, stitch length enlarged.

20.

28

/ Feeding tooth plane adjustment

Fig 28

21.

29

/ Synchronous feeding adjustment

Fig29

13

Loading...

Loading...