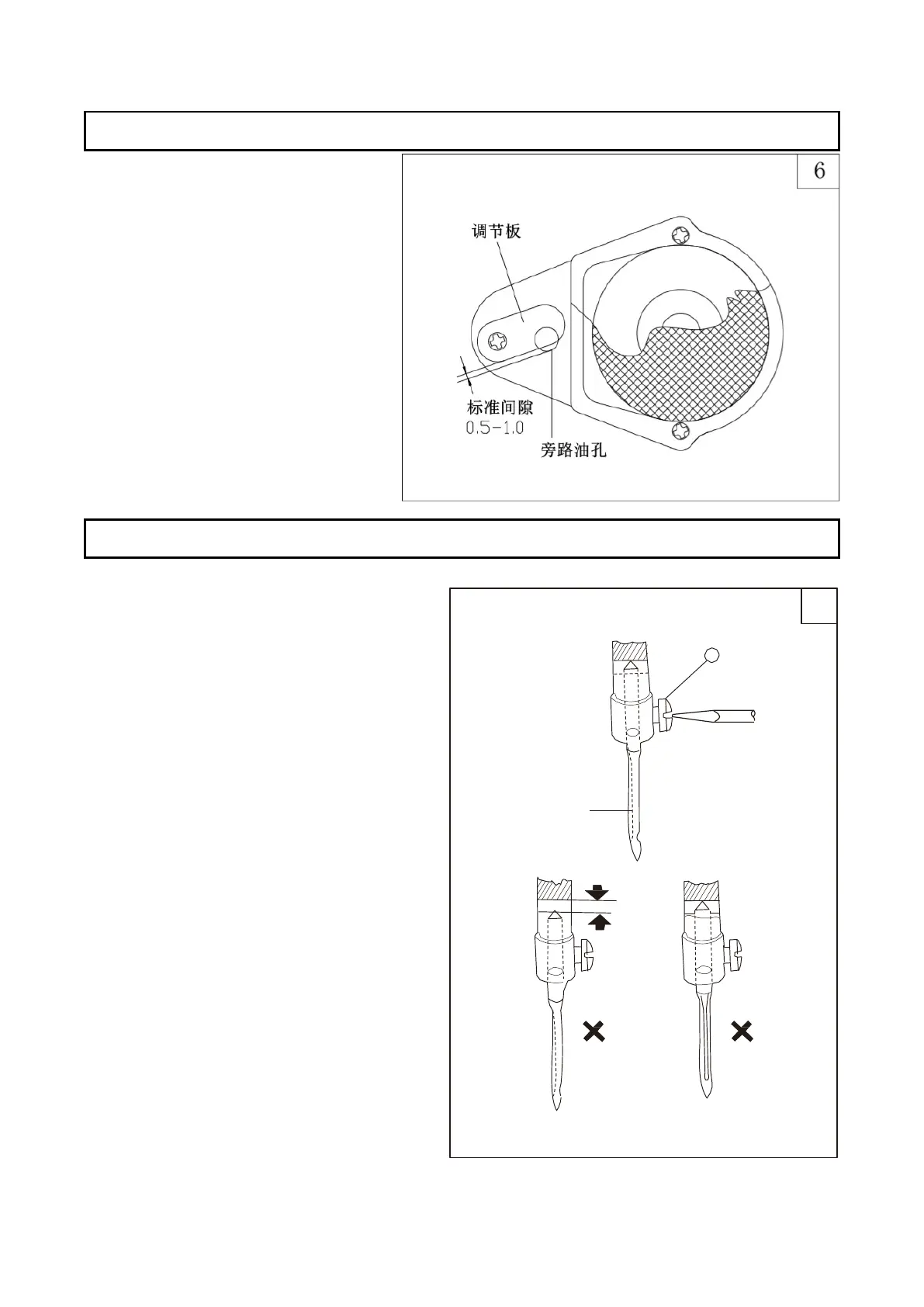

通常情况下,不作油泵进油调节,在

低速运转时,观察油窗,无喷油现象时,

请合拢间隙。

Generally no adjustment is for oil pump.

When the machine is running at a low speed,

observe the oil screen .If no oil splashing,

close the clearance.

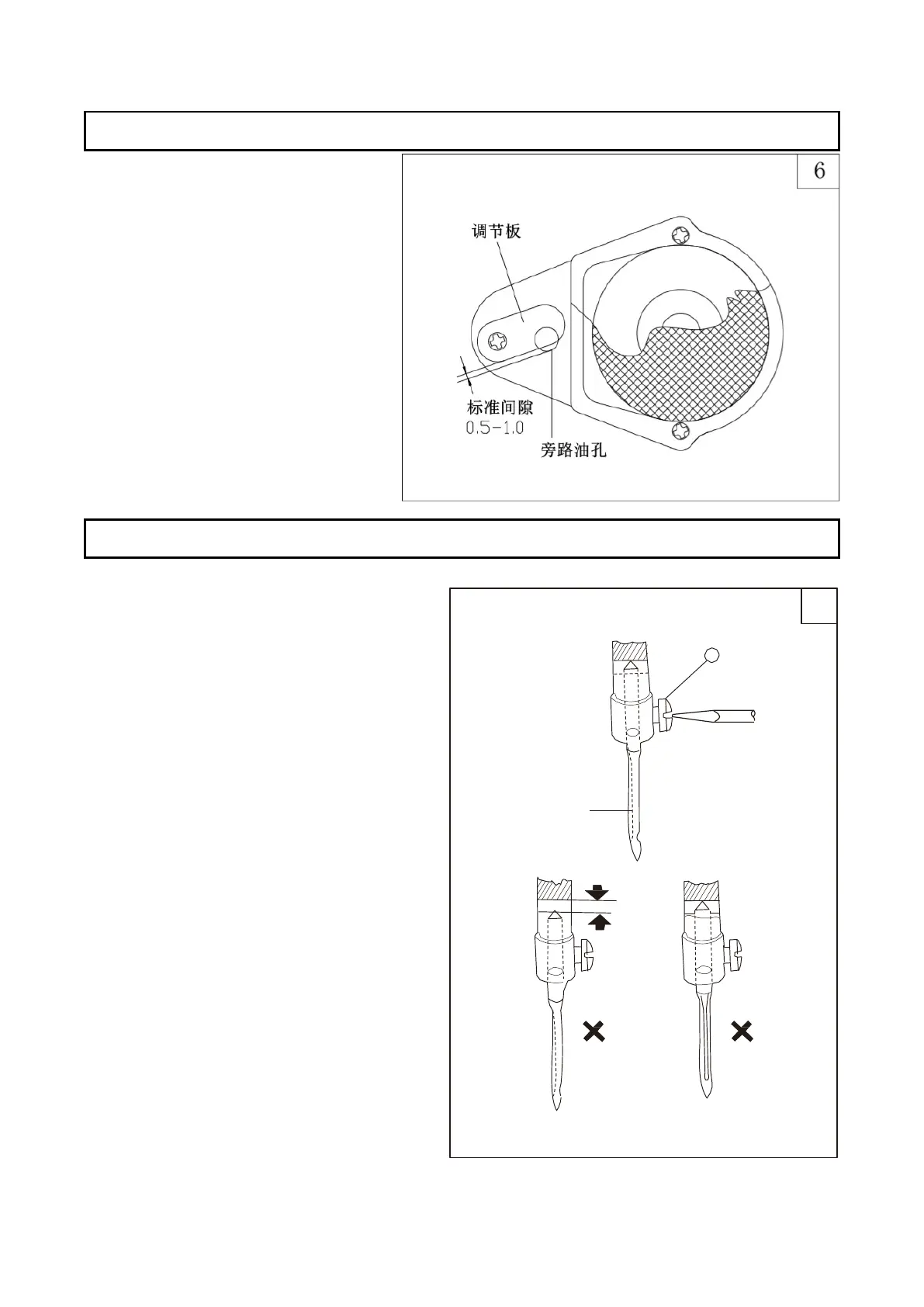

转动上轮,使机针上升到最高位置,旋松夹

针螺钉。将机针的长槽朝向操作者的左面,然后

把针柄插入针杆下部的针孔内,使其碰到针杆孔

的底部为止,再旋紧夹针螺钉 1 固定机针即可。

注意:如图(b)所示,机针没有碰到针杆孔

的底部。如图(c)所示针槽方向面对操作者,都

是错误的。

Turn the upper wheel to raise the needle to the

highest position and loosen the needle clamping

screw. Point the long groove of the needle toward

the left of the operator, and then insert the needle

handle into the needle hole at the bottom of the

needle bar until it touches the bottom of the needle

bar hole, and then tighten the needle clamp screw 1

to fix the needle.

Note: As shown in figure (b), the needle does

not touch the bottom of the needle bar hole. As

shown in figure (c), the direction of the needle

groove facing the operator is wrong

6.

6

/OIL PUMP SUPPLY ADJUSTMENT

Fig 6

7.

7

/Installing the needle

Fig 7

向左

4

Loading...

Loading...