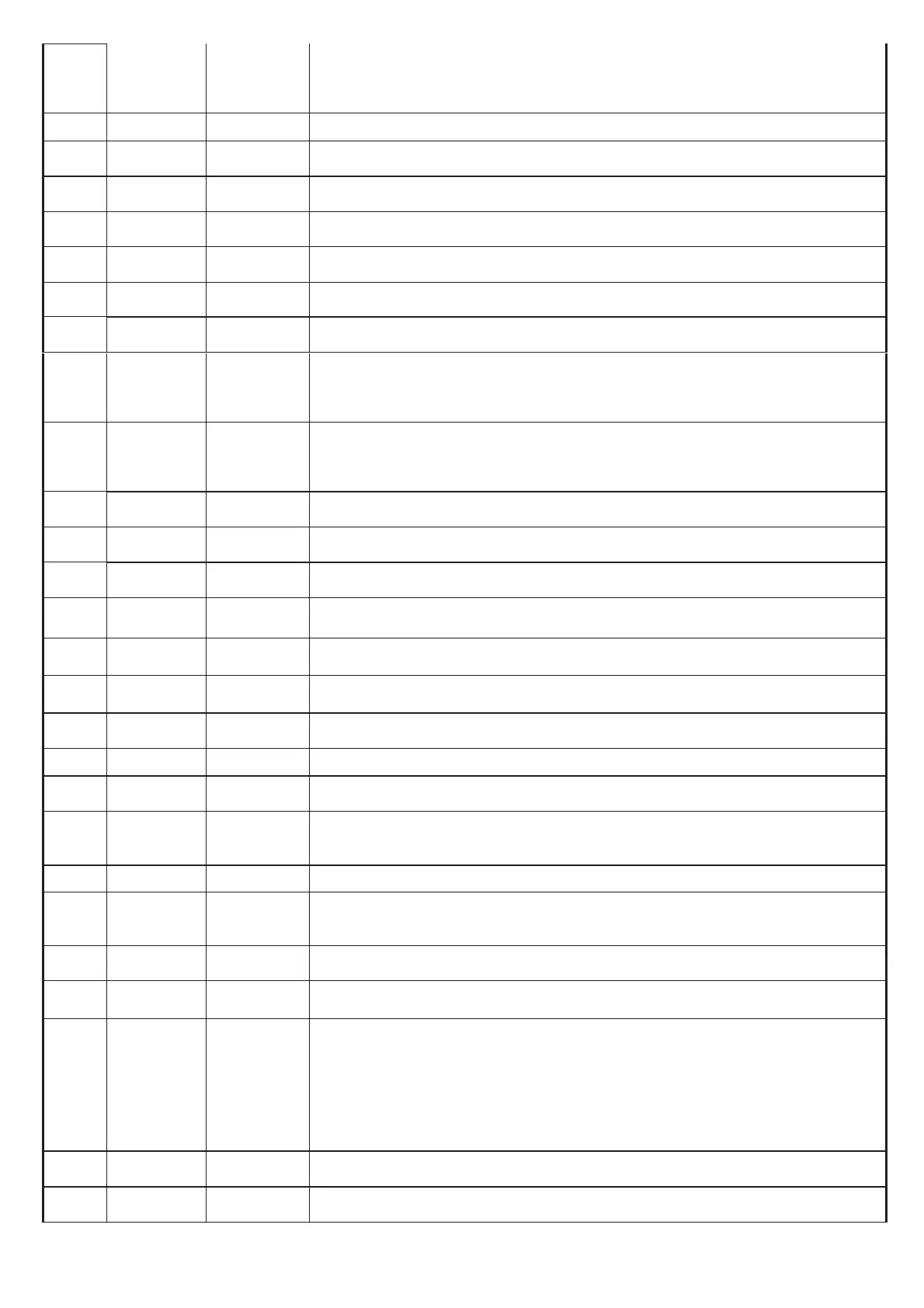

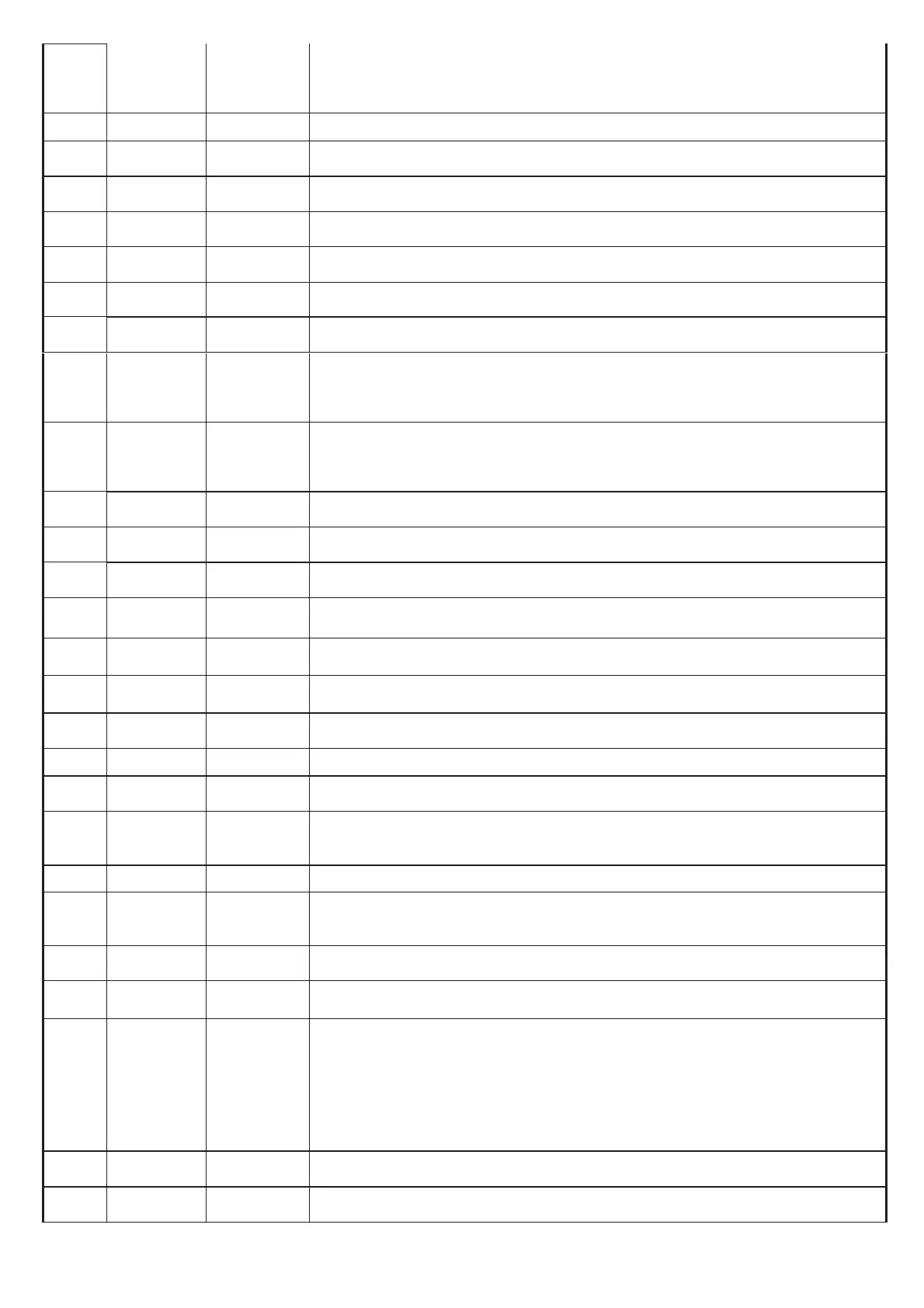

5/8

P17 0~99 0

presser foot sensor

setting (between the maximum and minimum

value of the 02C parameter display)

P27

0~3

1

Presser Foot sensor mode setting: 0: off 1: turn on only after trimming 2: always ON

P30

0~31 0

rward torque of motor: 0: normal functions 1-31: feedforward

P32 1~500 60

solenoid full open time (ms)

P33 0~100 6

am solenoid off time per cycle (ms)

P37

0~100

5

solenoid on time per cycle (ms), means the clamp strength.

P38

1~999

120

Flat seaming shear velocity (under the kni

fe to maintain time) -- -- -- -- -- -

P39

1~999

160

ging action time delay -- -- -- -- -- -- -- -- -- --

on the knife (note: this is also flat

seaming machine cut line)

P40

1~999

30

Duration and linear velocity (scan line)

-- -- -- -- -- -- -- --

on the knife (note: this is also flat

seaming machine cut li

ne)

P41

0~9999

120

to delay time(ms)

P42

1~9999

300

(ms)

P43

0~25

2

Sweep line, choice of blowing function (2 for scavenging; 8 for blowing)

P45

0~100

1

ming electromagnet per cycle opening time (ms)

P46

0~100

2

ming electromagnet per cycle closing time (ms)

P49

100~500

300

ming Speed

P50 1~500 100

electromagnet full output time ms

Presser foot lifting electromagnet per cycle opening time (ms)

P52 1~800 150

me when presser footer comes down (ms)

P53 0/1 1

function selection

Presser foot lifting electromagnet per cycle closing time (ms)

P56 0/1 1

Run to up needle position a

fter Power on喚

P57 0~600 200

electromagnet protection time 100ms

P60 200~5500 4000

he maximum speed of constant sewing (Automatic test speed)

P62 0~4 0

0: normal Mode

1: simply sewing mode

2: motor initial angle measurement (Do not remove the belt)

3: Automatically setting the pulley ratio by the CPU. (Synchronizer is necessary and the

belt not removed)

4:

automatic test modle 1 (It has needle stop position of automatic test, running

P66 0/2 2

function set: 0:off 2:on

P71 0~50 0

lifter level adjustment, the smaller values and the faster quickly

Loading...

Loading...