Correctly sizing the blower for your application is a critical step to the sustained operational quality

of your Jandy Pro Series Pool and Spa Blower. Damage or failure due to an improperly sized

blower is not covered under warranty.

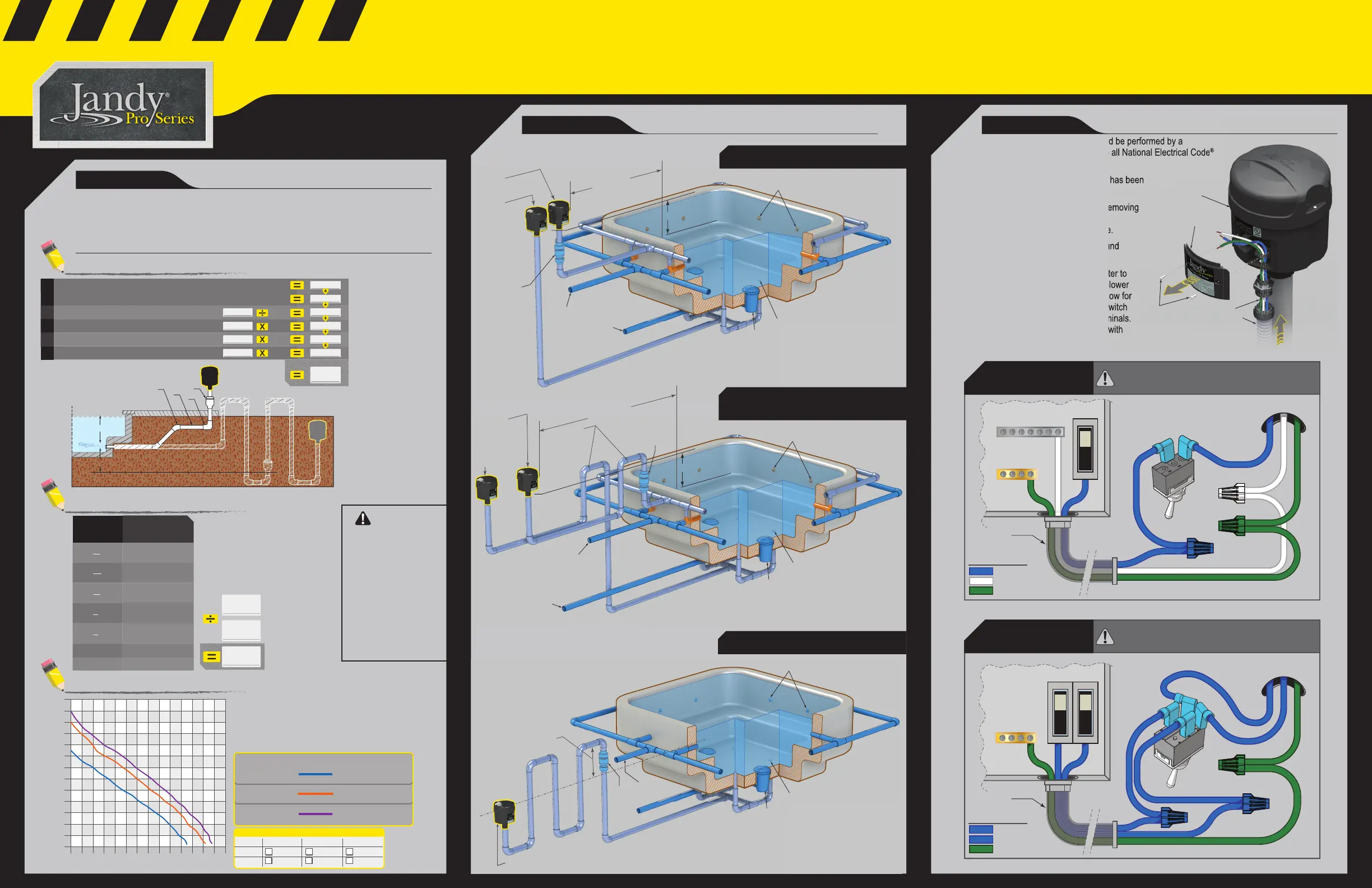

SIZING WORKSHEETS: The worksheets below will guide you through the proper sizing

calculations for your application.

1. SELECT BLOWER

2. PLUMBING 3. WIRING

Vertical Measure from Pool/Spa surface to air outlet

Number of feet of 2” Pipe

Number of 90° Elbows

Number of 45° Elbows

Number of 1/2 lb check valves

Total Back Pressure

(Inches of Water)

Calculate Back Pressure

4

a

b

c

d

e

Vertical Measure from air outlet to lowest check valve (See Note)

a

1

10

.5

.125

Calculate back

pressure as a measure

of “inches of water”.

Verifi cation of this

fi gure can be made by

using a manometer.

AIR HOLE

SIZE

CONVERSION

FACTOR

Calculate Airflow

1

″

8

5

″

32

3

″

16

1

″

4

3

″

8

1.2

″

0.15

0.1

0.27

0.6

1.1

1.5

2.4

Jet

Total Airflow

SCFM

(Standard Cubic Feet Per Minute)

Conversion

Factor

No. of Holes

Air Flow Rate (SCFM)

Pressure H

2

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

10

0

20

30

40

50

60

70

80

90

100

110

120

Performance Curves (60 HZ)

Models: PSB110

Models: PSB115

Models: PSB120

Max Back Pressure 40"

Max Back Pressure 50"

Max Back Pressure 65"

Models: PSB210

Models: PSB215

Models: PSB220

Voltage

Blower Selection

120V

1.5 HP 2.0 HP1.0 HP

PSB110

PSB115 PSB120

240V

PSB210 PSB215 PSB220

Determine Blower Needed

Choose an air hole size from

the chart at left and apply the

conversion factor in the formula

below to determine total airfl ow in

standard cubic feet per minute.

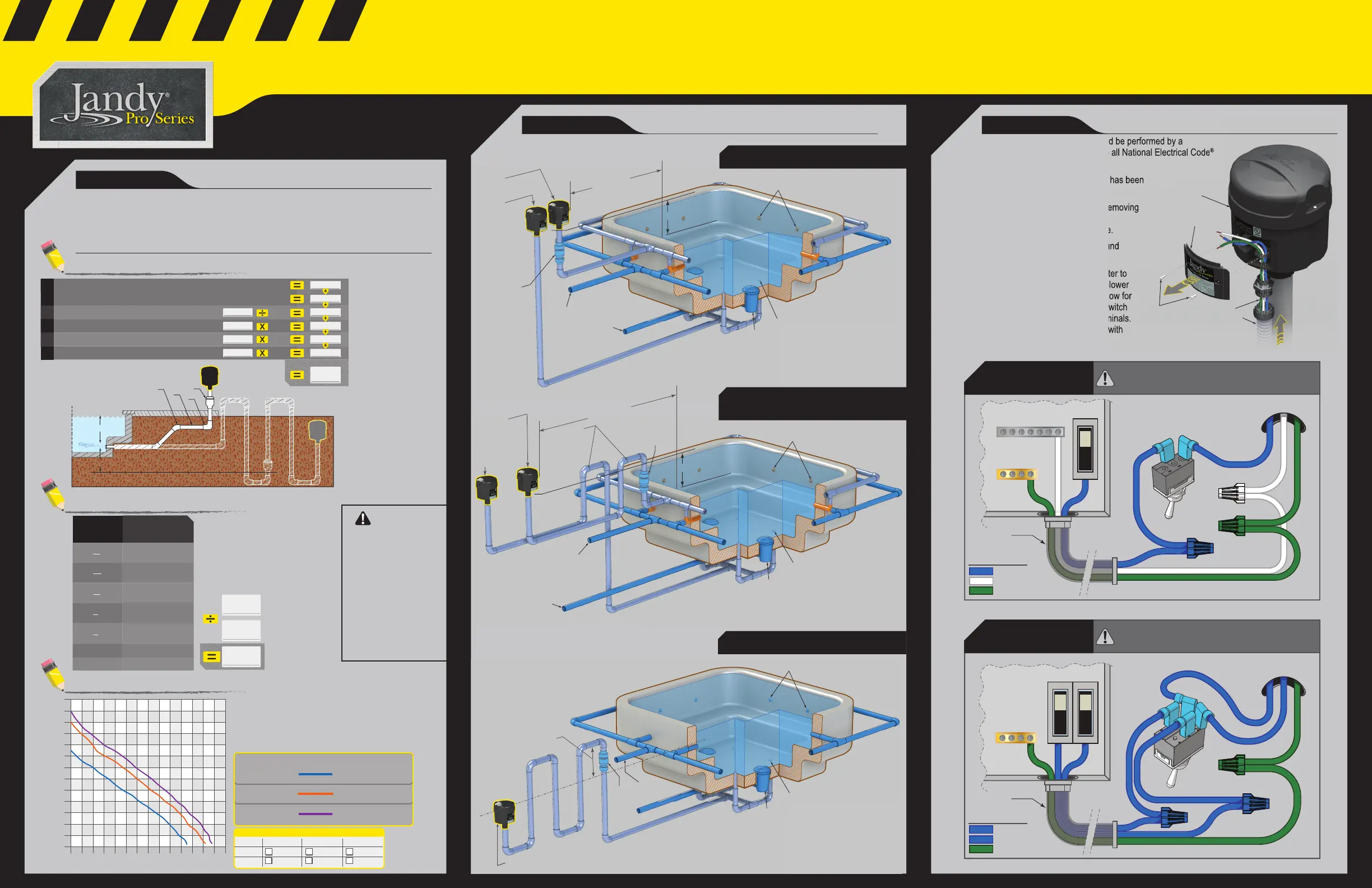

Installation of this equipment should be performed by a

licensed electrician and conform to all National Electrical Code

®

(NEC

®

), state and local codes.

1. Ensure all power to the blower has been

disconnected at the main breaker.

2. Remove blower front door by removing

the two (2) screws sliding the door

downward and pulling the door free.

3. Pull in voltage source and ground

wire from Power Center.

4. Connect wires from power center to

the corresponding wires from the blower

motor. Use the wiring diagrams below for

reference. The 120 or 240 toggle switch

will come preinstalled with fl ag terminals.

Connections will need to be made with

Wire nuts.

WARNING

Installing an insuffi ciently

sized blower will

increase back pressure.

Failure to accurately

follow the blower

sizing calculations

provided could result

in excessive back

pressure. Excessive

pressure can cause

damage that could result

in electrocution causing

severe injury or death.

Water Line

Water Line

Air Line

Check Valve*

Spa Return

To Pump

Sump

to water level

12” min.

5’ - 25’

min.

max.

Bubbler Jet

Venturi Jet

†

Blower

(installation with

Venturi Jets

†

)

Blower

(installation with

Bubbler Jets)

* Install a 1/2 lb. U.L. listed check valve between the

blower and the jets to prevent water damage to the blower.

Ensure that check valves are accessible for servicing.

†

Do not install adjustable jets. These may cause

excessive back pressure.

ON

OFF

Line 1

Neutral Bus Bar

Ground Bus Bar

From Blower Motor

From Power Center

Power Center

120V Toggle Switch

Flex Conduit

120V Wiring

RISK OF ELECTRIC SHOCK WHICH CAN RESULT IN SERIOUS

INJURY OR DEATH. Before attempting installation, ensure that all

power to the device is disconnected/turned off at the circuit breaker.

Be careful not to damage or abrade any wiring or other components.

LEGEND

Line 1

Neutral

Ground

ON

OFF

Line 2

ON

OFF

Line 1

Ground Bus Bar

From Power Center

Power Center

Flex Conduit

From Blower Motor

240V Toggle Switch

LEGEND

Line 1

Line 2

Ground

240V Wiring

RISK OF ELECTRIC SHOCK WHICH CAN RESULT IN SERIOUS

INJURY OR DEATH. Before attempting installation, ensure that all

power to the device is disconnected/turned off at the circuit breaker.

Be careful not to damage or abrade any wiring or other components.

Water Line

Air Line

Check Valve*

Sump

Spa Return

to water level

12” min.

Over 25 Feet

Hartford loop

Plumb as

close to the

pool/spa wall

as possible.

Bubbler Jet

Venturi Jet

†

* Install a 1/2 lb. U.L. listed check valve between the blower

and the jets to prevent water damage to the blower.

Ensure that check valves are accessible for servicing.

†

Do not install adjustable jets. These may cause excessive

Blower

(installation with

Venturi Jets

†

)

Blower

(installation with

Bubbler Jets)

LONG RUN INSTALLATION

(over 25’ from spa wall)

STANDARD INSTALLATION

Installation of this equipment should be performed by a

licensed electrician and conform to all National Electrical Code

Ensure all power to the blower has been

Remove blower front door by removing

downward and pulling the door free.

Pull in voltage source and ground

Connect wires from power center to

the corresponding wires from the blower

motor. Use the wiring diagrams below for

reference. The 120 or 240 toggle switch

will come preinstalled with fl ag terminals.

Connections will need to be made with

Screw

Conduit

Wires

Blower Door

Blower

From

Power Center

2” min.

water

level

Check

Valve*

Sump

Bubbler Jet

Blower

Water Line

Air Line

Spa

Return

To

Pump

* Install a 1/2 lb. U.L. listed check valve between the

blower and the jets to prevent water damage to the blower.

Ensure that check valves are accessible for servicing.

Hartford Loop -

To install the

blower below

water level, or if

the blower air

line drops

below the

bottom of the

spa, use the

Hartford Loop

plumbing

configuration to

prevent the air

line from filling

with water.

BELOW GRADE INSTALLATION

a

a

1

Spa

Deck

Grade

Blower

e

d

b

c

NOTE: Include a

1

for

installations with a check

valve below the air outlet

only. See “Below Grade

Installation” on facing page

for details. For above grade

installations enter 0 for a

1

.

Locate the total back pressure, calculated above

and draw a horizontal line. Locate the total airfl ow

from previous step and draw a vertical line. These

lines will intersect on the performance curve of the

minimum HP blower required for your application.

Loading...

Loading...