4

ENGLISH

The amount of cream used for each soldering

operation should be just sufficient to cover the

trace of the component pin. Any excess cream

may extend over the circuit on melting and

cause short-circuits.

5) Move the nozzle tip to about 15-20 mm

from the component terminal and direct

the hot air flow against it. Wait for a few

seconds until the cream flux liquefies.

During this time the terminal will be

preheated to about 100°C. Move the tip

closer to 8-10 mm and hold it just until the

tin alloy melts. Immediately remove the

heater. If the solder area is overheated, it

oxidizes making soldering difficult and

there is a risk of damaging the component

or the printed circuit copper adhesive.

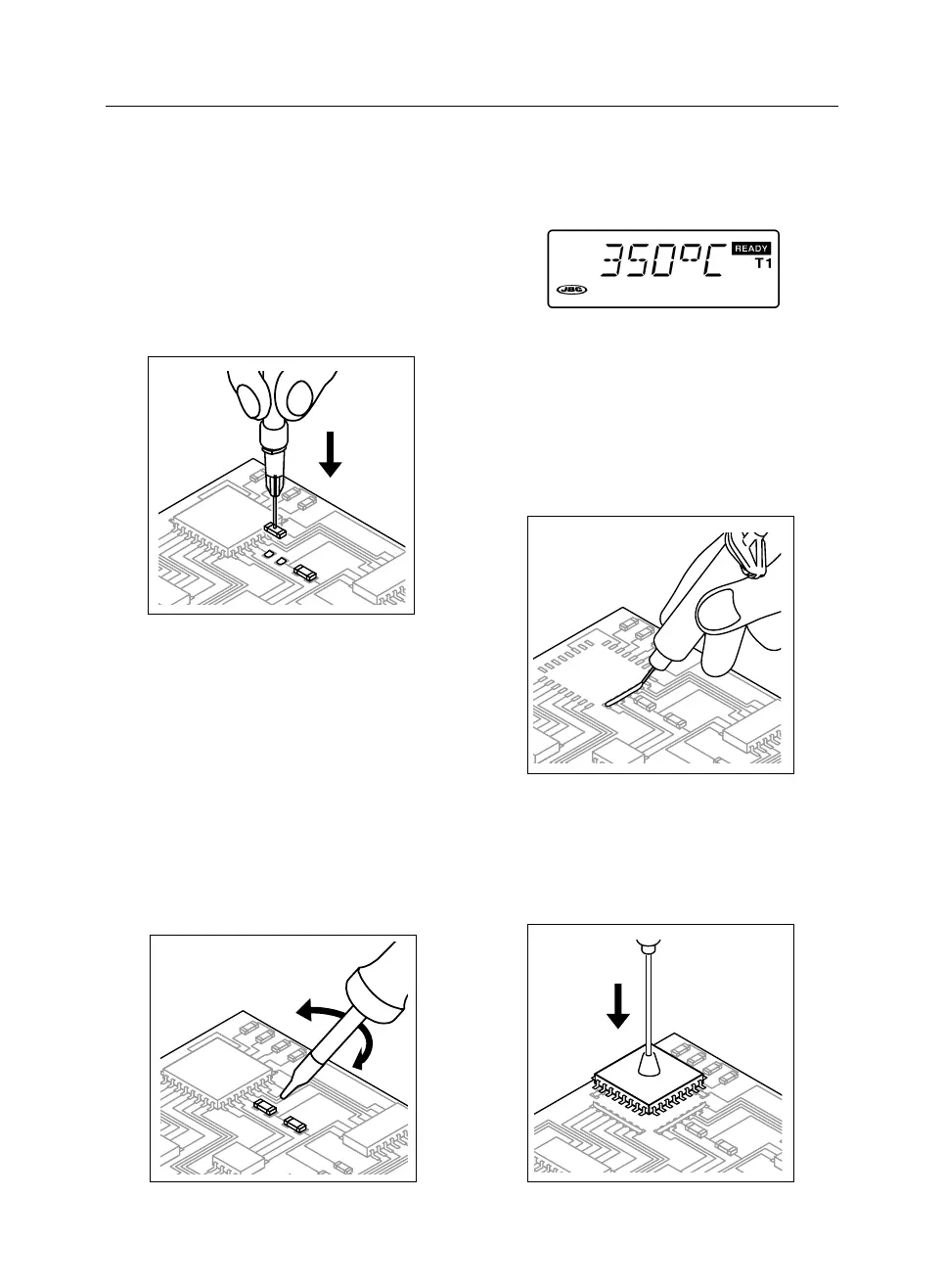

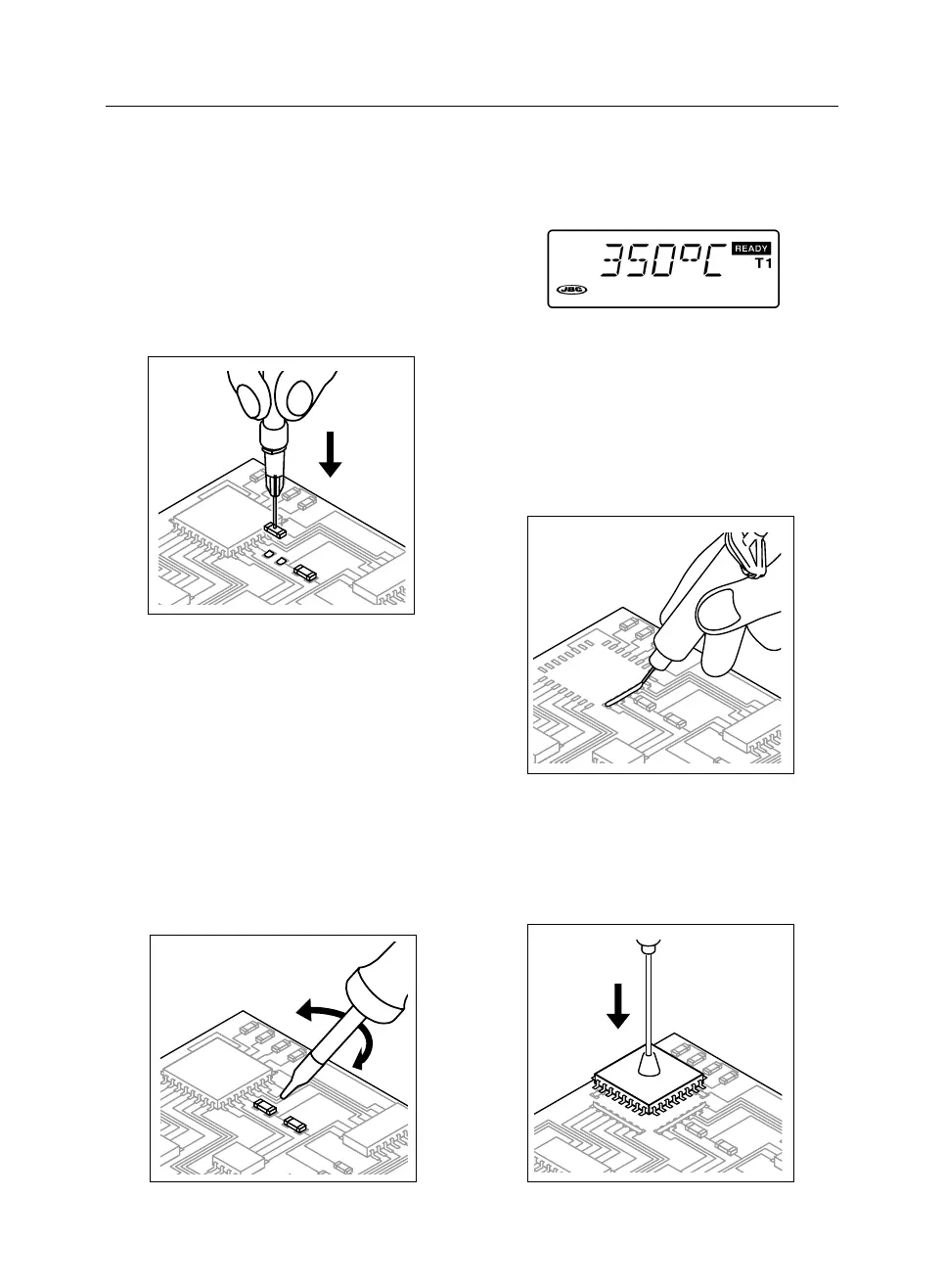

4) Take the component with a JBC PK 6060 or

DP 6070 Pick & Place or otherwise with fine

pincers, place it in position on the circuit and

hold it in place.

Process for printed circuits in PLCC, QFP, SO

encapsulations:

1) Temperature of about 350°C, air flowrate 1-7.

2) Apply soldering cream (*) for SMD on the

circuit pads, forming a bead transverse to

the direction of the tracks. In this operation,

it is vital not to apply too much cream, since

any excess may lead to solder cross-

connections being formed between the

component’s pins.

3) Take the component with the PK 6060 or DP

6070 Pick & Place, place it in position on the

circuit and hold it in place.

Loading...

Loading...