13 - 4

Assembly (cont’d)

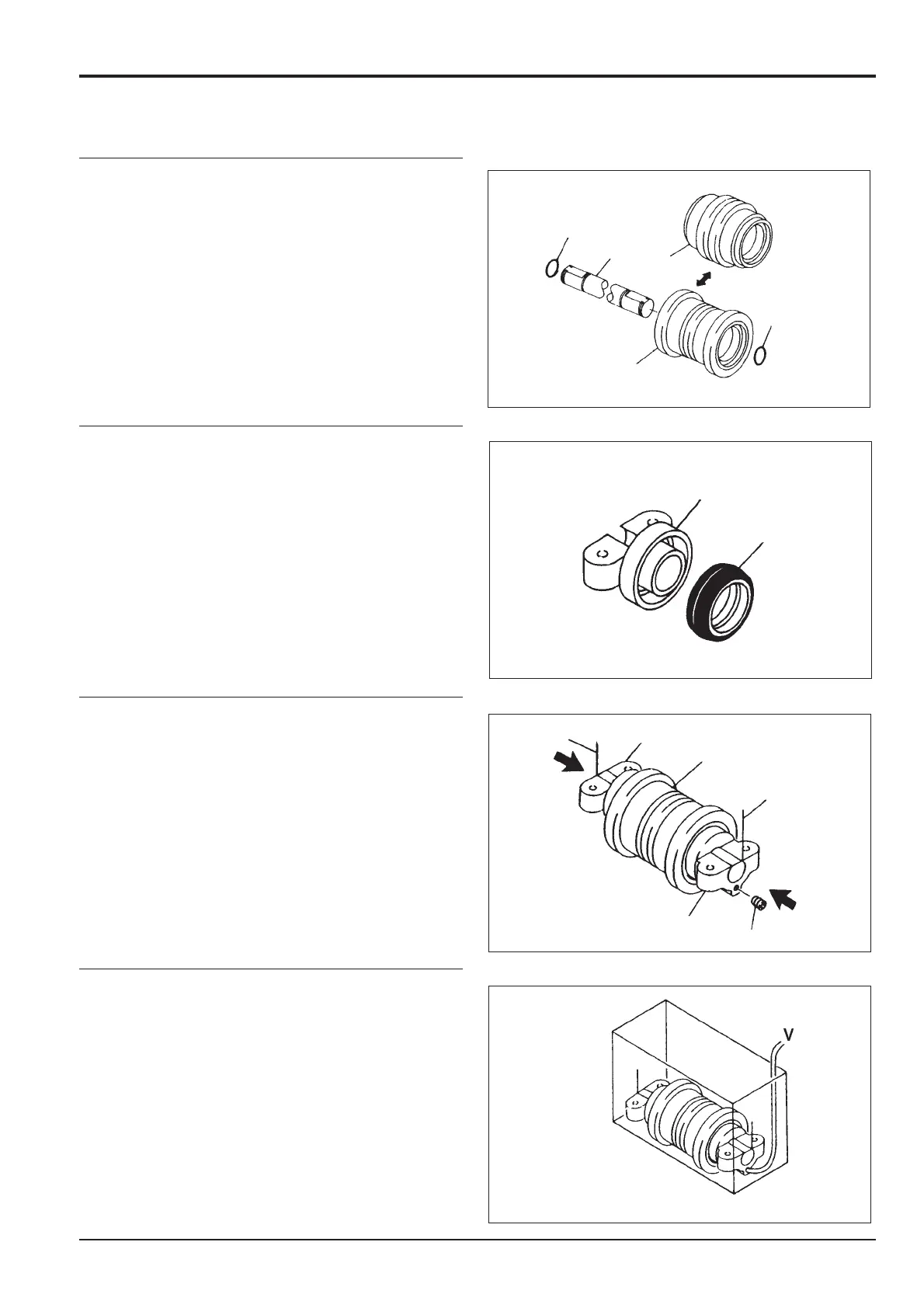

3 Coat shaft C with grease. Insert the shaft into roller H or

J. Apply grease to new 'O'-rings G and install them on

shaft C.

4 Install new floating seals F into brackets D and E. Coat

the metallic face of each seal with engine oil.

5 Press mounting brackets D and E onto shaft C and

partially insert new locking wires B.

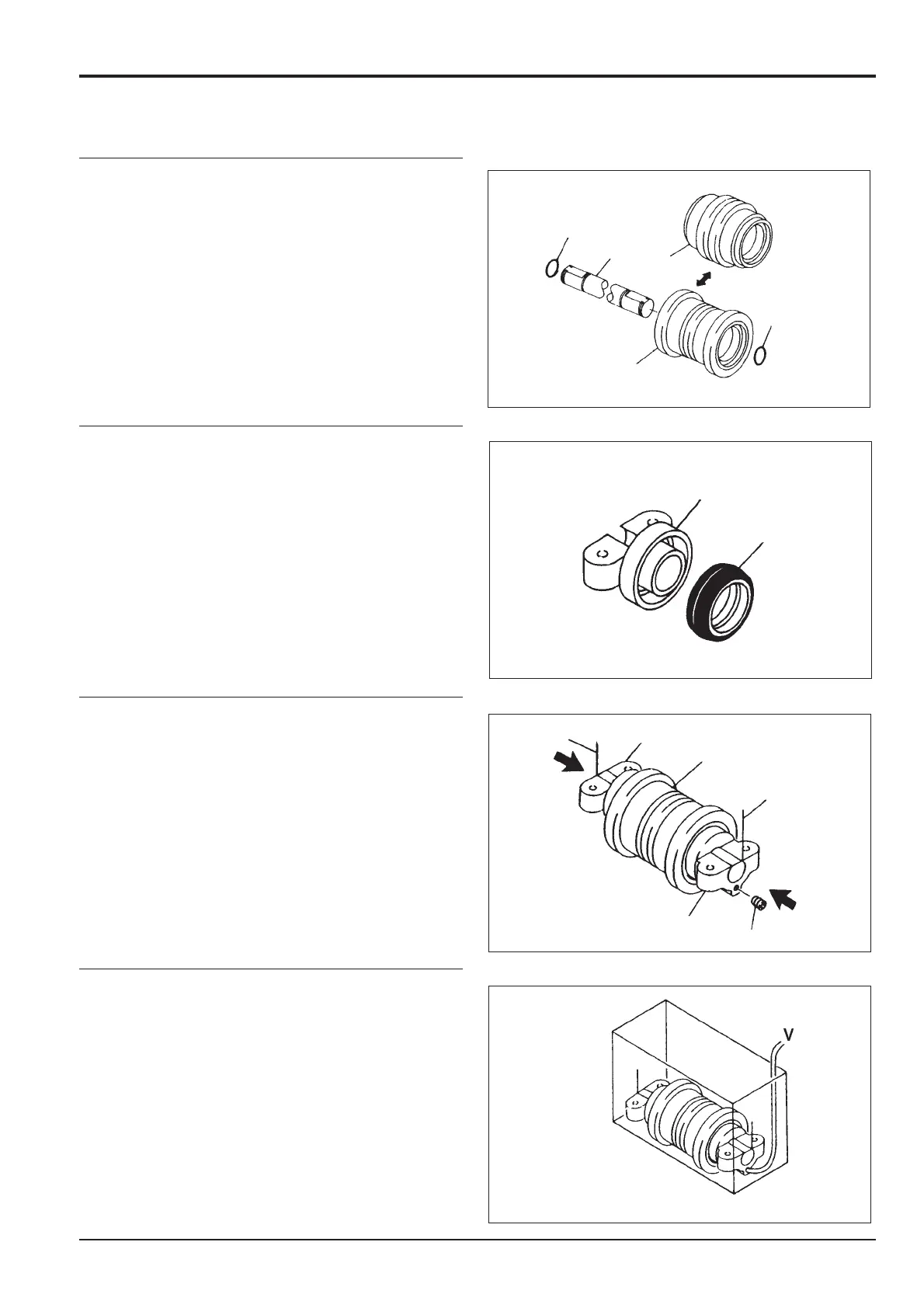

Wrap sealing tape around one plug A with one thread

remaining uncovered. Install this plug, but leave the

other one out until after pressure testing (step 6).

6 Connect compressed air pipe V to the vacant plug A

port. Using extreme care to prevent water entering the

assembly, lower it into a tank of water.

Apply air pressure of 1.9 bar (28 lbf/in

2

) and check that

there are no bubbles leaking from the unit. If leakage

occurs dismantle and re-assemble, taking extra care

when fitting new seals.

Section J Track and Running Gear

9803/6410

Section J

13 - 4

Issue 1

Bottom Roller

J

G

C

G

H

F

B

E

B

A

D

C

D,E

JS01600

Loading...

Loading...