27 - Driveline

06 - Semi-Automatic Gearbox

12 - Clutch - Ratio

27 - 128 9813/6850-2 27 - 128

Item Description

P O-ring seal 3

Q Housing

R Gallery port

S O-ring seal 1

Assembly

Assembly is the opposite of the disassembly

procedure with the following precautions.

1. Install the new clutch piston O-ring seals 2 and

seal 3 to the piston.

2. Lubricate the new seals and push the piston into

the housing by hand.

3. Put the lower spring cup over the central spigot

of the piston.

4. Replace the spring and the top spring cup.

5. Keep the circlip 2 on the top cup ready for

installation.

6. Use the tube with a cutout to compress the

spring.

7. Locate the cutout to give access for circlip 2.

8. Install the circlip 2 and make sure that it is seated

correctly in the groove.

9. New clutch friction plates must be soaked in oil

before assembly.

10. Install the first counter plate to the clutch drum

followed by the friction plate.

11. Alternately install all fourteen plates.

12. Use a scrap splined drive hub to align the splines

of the friction plates.

13. Install the thick counter plate at the top of the

assembly followed by the circlip 1.

14. Check the free play clearance of the clutch plates

and it must be within the specified limit.

Dimension: 3 –3.5 mm

15. You can adjust the clearance by either changing

the thick pressure plate from 6.0mm (0.24in)

thick version to 6.5mm (0.26in) thick or by

the addition of a shim counter plate installed

immediately under the thick pressure plate.

16. Once the clutch is assembled completely then

apply compressed air to the gallery port in the

end of the shaft to check the clutch operation.

Ratio Clutches

Disassembly

1. For the remaining two ratio clutches follow the

same disassembly procedure as above.

2. The only difference is the retention of the support

taper roller bearing which for each clutch is held

in place by a machined cap.

Assembly

1. Clutch 1 and clutch 2 assembly.

1.1. Use a mandrel to carefully push the taper

bearing 1 into its position.

1.2. Rotate the roller cage as the bearing is

pushed into place to make sure that the

mandrel does not foul and distort the cage.

1.3. Put the new O-ring seal 4 into the grooves

in the cap 1.

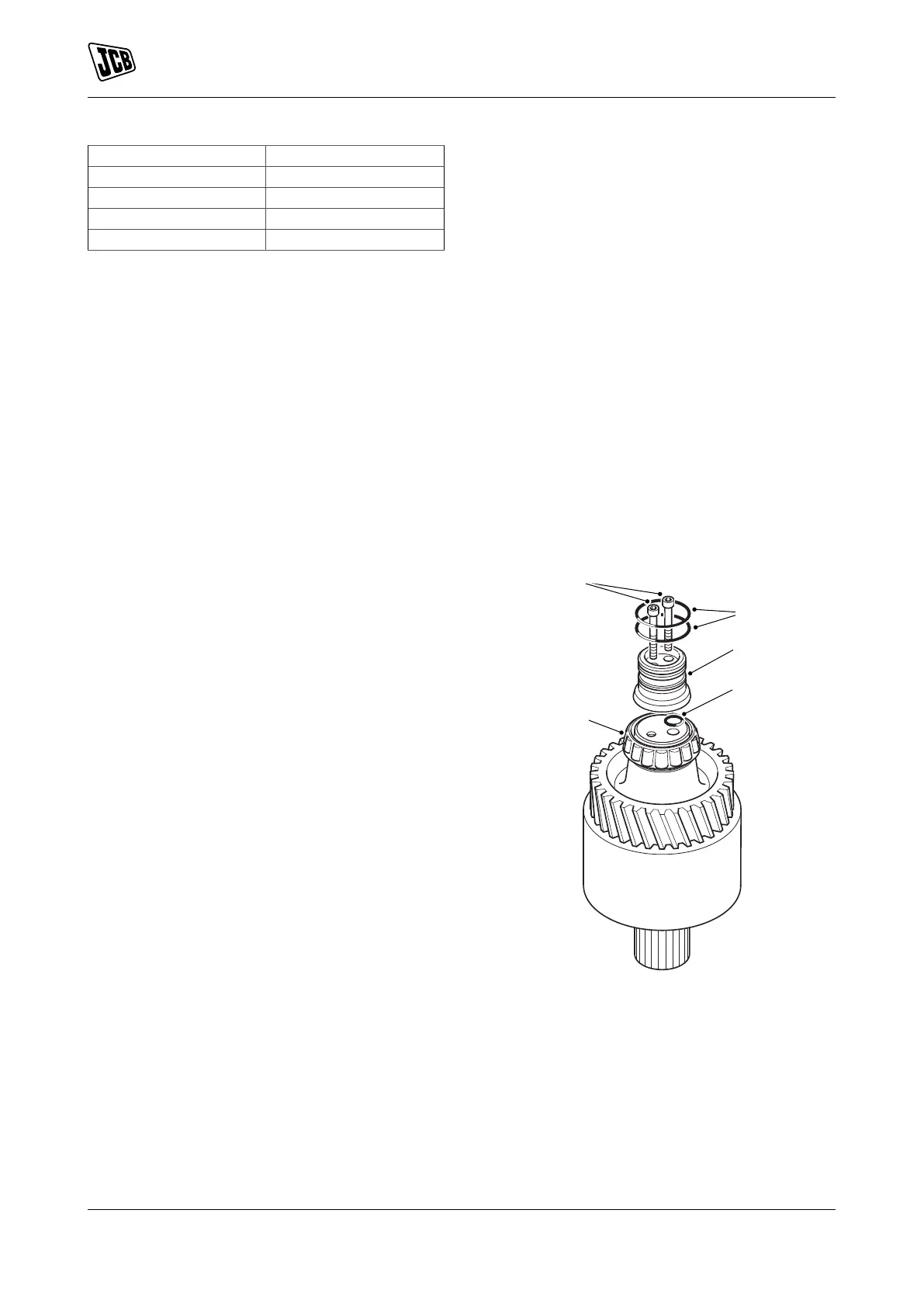

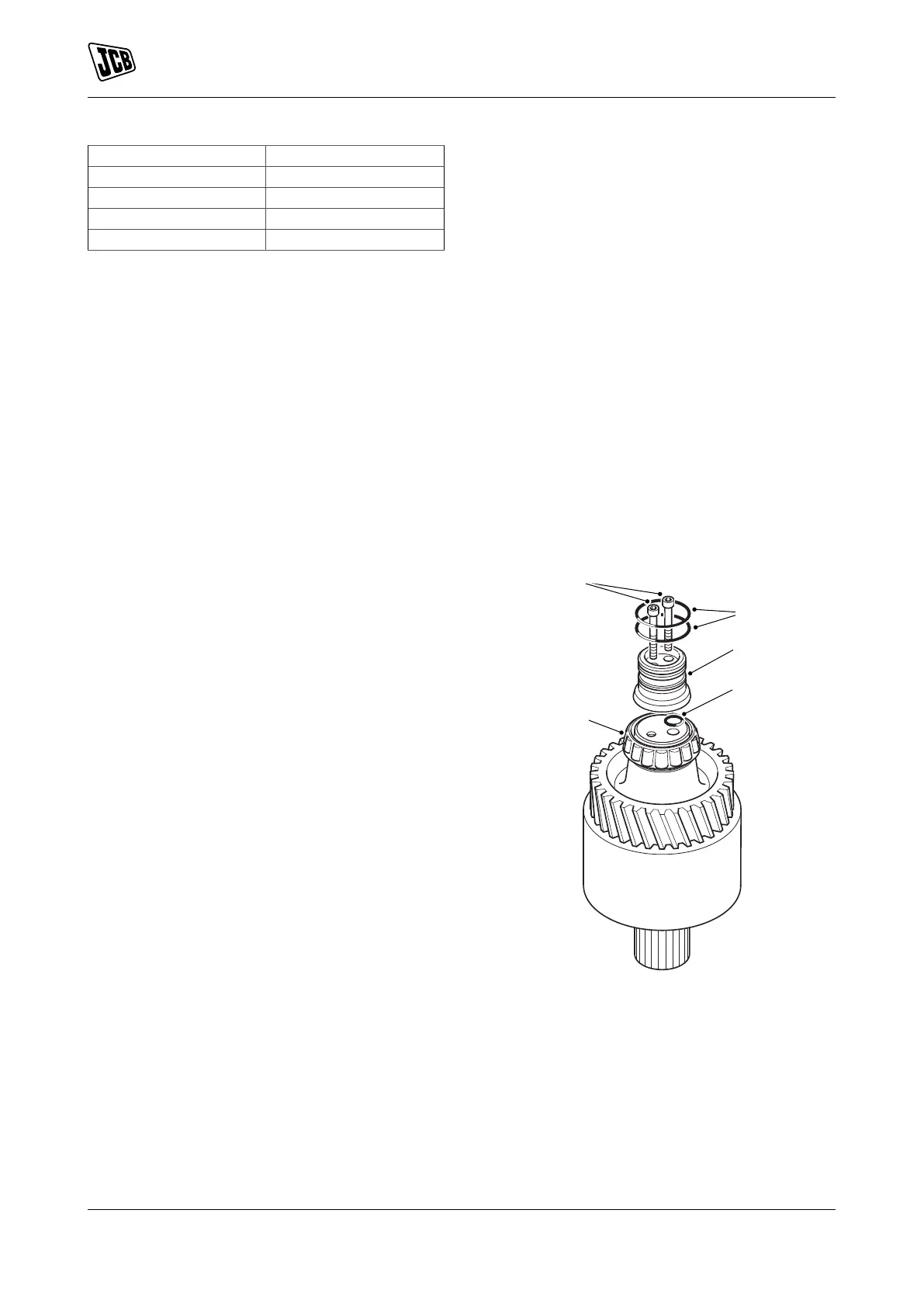

Figure 569.

T Taper bearing 1

U O-ring sea l4

V Cap 1

W Capscrews 1

X O-ring seals 5

1.4. Two capscrews 1 hold the cap 1 in place.

1.5. Tighten the capscrews 1 to the correct

torque value.

1.6. Put two new O-ring seals 5 into the groves

in cap 1.

Loading...

Loading...