Page 10

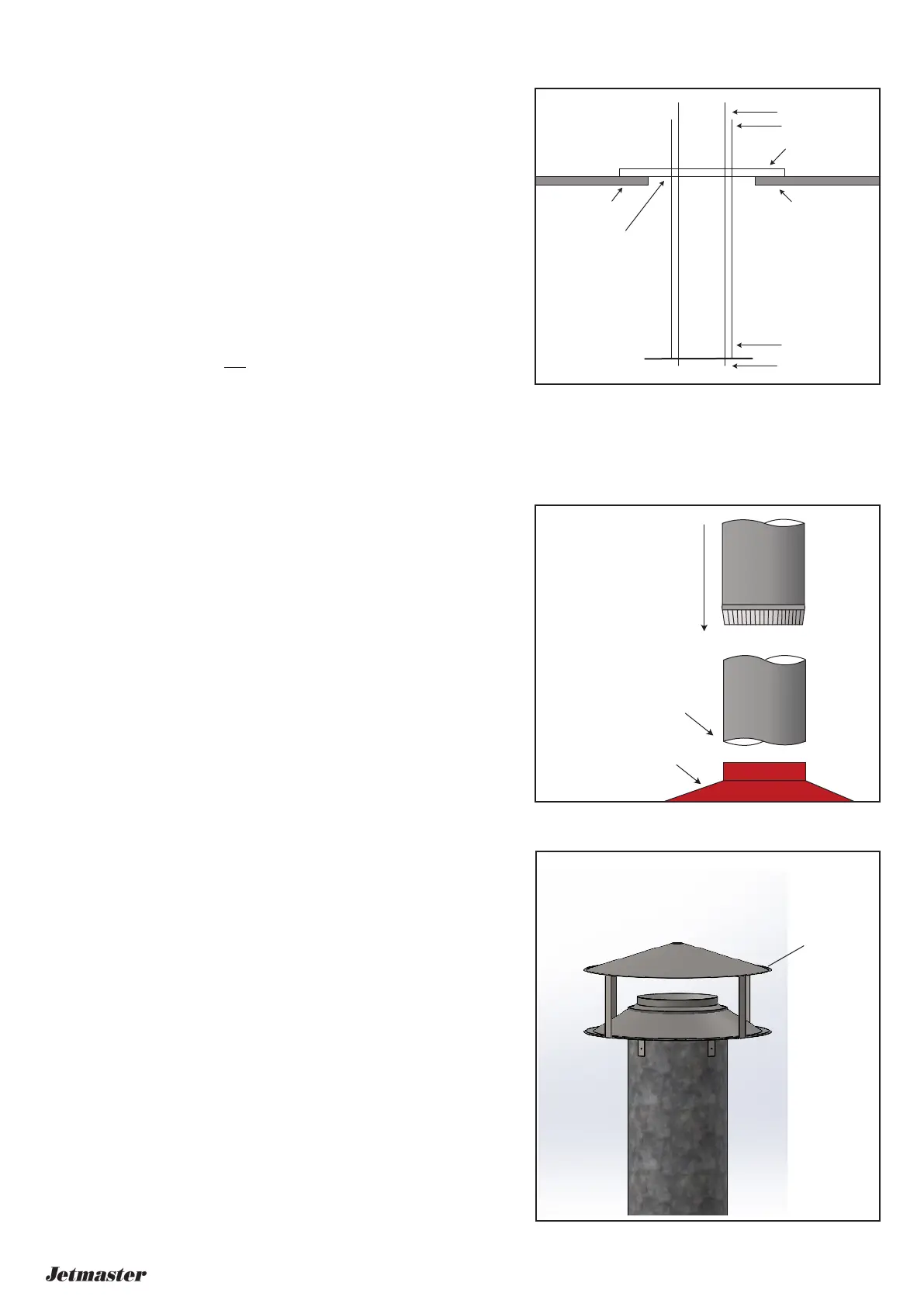

Ceiling penetration

clearances

5. Flue & chimney requirements cont...

Existing chimneys should be inspected and cleaned by a qualied

professional prior to installation. The chimney must not have cracks,

loose mortar or other signs of deterioration and blockage. Jetmaster

recommends a certied professional or a technician, under the

direction of a certied professional.

Single skin ue (stainless steel) must be completely enclosed with

single skin brickwork, concrete, or autoclaved aerated concrete

block. A chimney plate will be used to weather seal the chimney.

Twin skin ues (stainless steel inner, and galvanised outer) can

either be left exposed or enclosed with stud walls and sheet plaster

or timber. A minimum of 50mm clearance must be maintained

between the outer ue and any combustibles within the chase or

ceiling cavity. (Fig 5.1)

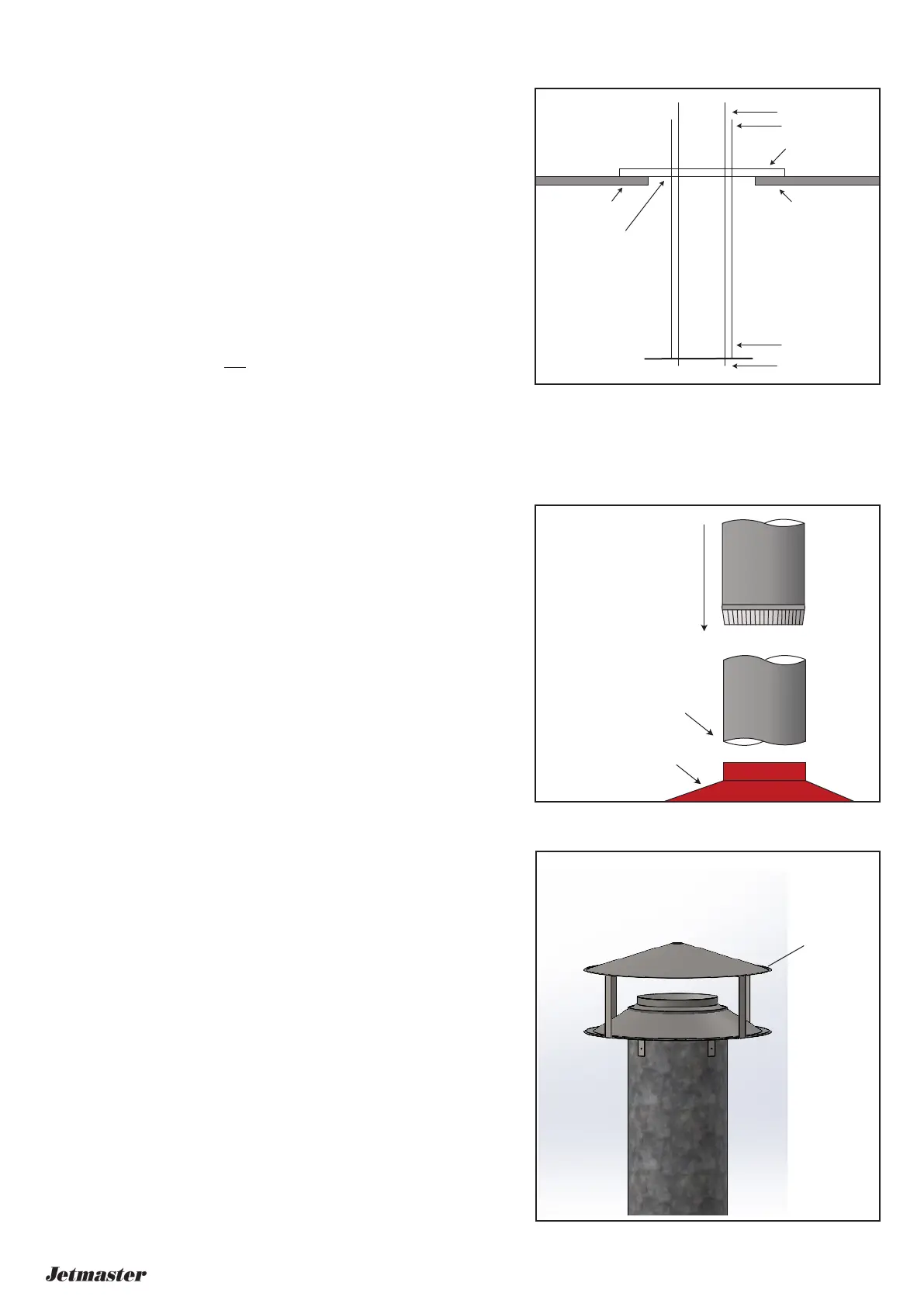

Position an active starter ue with two female ends to gather to

allow second length to have crimp facing down. (Fig 5.2)

Glass

tape

may

be

required

to

ensure

a

snug

t.

The outer ue is then installed outside active ue with crimp facing

up to ensure water penetration on ue above roof runs out.

Rivet active ues together at crimped joins.

Fix outer non-active ues to active inner ues use 3 x 25mm self-

tapping screws through outer ue at bottom at each join and on top

at each join. As an alternative, rivet 4 x 25mm conduit saddles at

each join top and bottom.

Cowl

For

solid

fuel

applications

only

, a double cone cowl will assist in

preventing the effects of downdraft. (Fig 5.3)

Other solid fuel cowls may be desired to achieve a visual design

and such cowls can be used but must not restrict airflow from

the flue pipe casings.

For

gas

applications

an AGA approved cowl must be used.

Fig 5.2

Fig 5.3

Fig 5.1

Combustible ceiling

Combustible ceiling

Support angles

50mm gap from

Combustible materials

Outer Gal casing

Active stainless steel

Active stainless steel

Outer Gal casing

Crimped end down

From second length

Gather

Trim the crimp off first

length stainless pipe

Double cone

cowl

Loading...

Loading...