RXF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.410-IOM (JAN 12)

Page 9

Liquid line sizes and the additional receiver volume (quanti-

ty of refrigerant required for 5 minutes of liquid injection oil

cooling) are given in the following table:

FLOW

RXF

LIQ. LINE SIZE*

RATE LIQUID

REFRIG MODEL

PIPE TUBING

(lb) VOLUME

SCH 80 OD 5 MIN CU. FT

R-717

HIGH

STAGE

12 1/2 – 10 0.3

15 1/2 – 12.5 0.4

19 1/2 – 15 0.4

24 1/2 – 20 0.6

30 1/2 – 25 0.7

39 1/2 – 30 0.8

50 3/4 – 40 1.1

58 3/4 – 47 1.3

68 3/4 – 55 1.6

85 3/4 – 70 2.0

101 3/4 – 80 2.3

R-507

HIGH

STAGE

12 3/4 7/8 17 0.3

15 3/4 7/8 20 0.3

19 3/4 7/8 22 0.4

24 3/4 7/8 31 0.5

30 3/4 7/8 36 0.6

39 3/4 7/8 42 0.7

50 1¼

1C\,

56 0.9

58 1¼

1C\,

68 1.1

68 1¼

1C\,

78 1.2

85 1¼

1C\,

97 1.5

101 1¼

1C\,

120 1.9

R-717

BOOSTER

12 1/2 – 2.0 0.1

15 1/2 – 2.5 0.1

19 1/2 – 3.5 0.1

24 1/2 – 4.5 0.1

30 1/2 – 5.5 0.2

39 1/2 – 6.5 0.2

50 1/2 – 8.5 0.3

58 1/2 – 10 0.3

68 1/2 – 12 0.3

85 1/2 – 15 0.4

101 1/2 – 18 0.5

R-507

BOOSTER

12 3/8 1/2 5.5 0.1

15 3/8 1/2 6 0.1

19 3/8 1/2 7 0.1

24 3/8 1/2 10 0.2

30 3/8 1/2 11 0.2

39 3/8 1/2 13 0.2

50 3/4 7/8 17 0.3

58 3/4 7/8 23 0.4

68 3/4 7/8 26.5 0.4

85 3/4 7/8 33 0.5

101 3/4 7/8 40.5 0.6

* 100 ft. liquid line. For longer runs, increase line size accordingly.

High-stage compressor units may be supplied with single-port

(low Vi, side, or closed thread) or dual-port (low Vi and high Vi),

liquid injection oil cooling. Single port will be furnished for low

compression ratio operation and dual port for high compres-

sion ratio operation. Booster compressor units use single-port

(High Vi), liquid injection oil cooling due to the typically lower

compression ratios.

The control system on high-stage units with dual-port, liquid

injection oil cooling switches the liquid refrigerant supply to

the high port when the compres sor is operating at higher

compression ratios (3.5 Vi and above) for best efciency.

Where low compres sion ratios (low condensing pressures)

are anticipated, thermo syphon or water-cooled oil cooling

should be used.

It is imperative that an uninter-

rupted high-pres sure liquid refrig-

erant be provided to the injection

system at all times. Two items of EXTREME IMPORTANCE

are the design of the receiver/liquid injection supply and

the size of the liquid line. It is recommended that the

4. Welding should occur in two segments, from 6:00 to 12:00.

The maximum intersegment temperature should be 350°F.

Temperature should be veried with temperature indicating

crayon or equivalent.

5. The tting may be cooled with forced air to reduce the

temperature of the tting to 350°F or lower, prior to welding

the second segment.

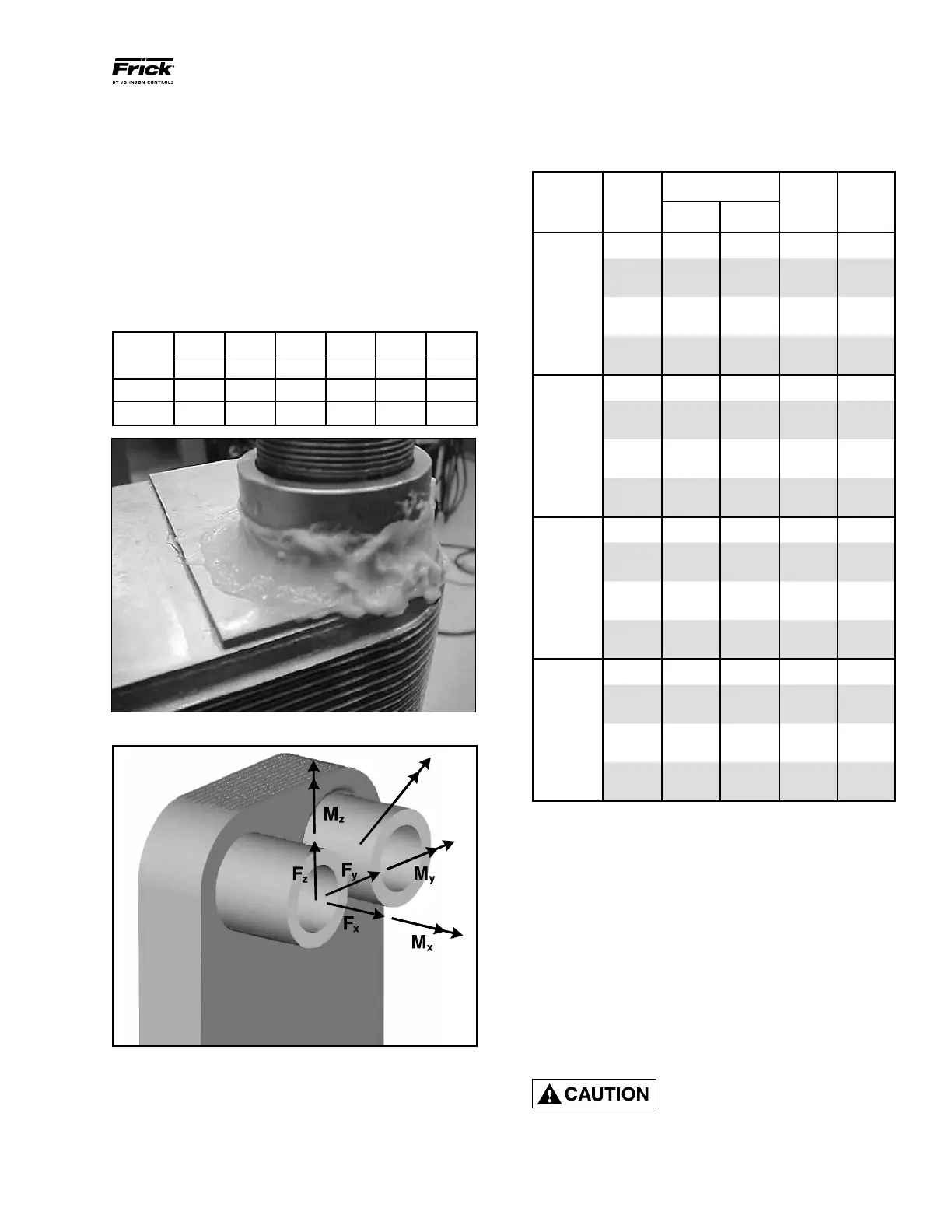

The maximum connection static forces and moments for Alfa

Nova heat exchangers are listed in the following table.Keep

these values in mind when designing your system. It is also

recommended to minimize connection loads when designing

piping systems. Also see Figure 6.

Fx Fy Fz Mx My Mz

(lb

f

) (lb

f

) (lb

f

) (lb

f

ft) (lb

f

ft) (lb

f

ft)

ANHP52 202 13 13 57 32 32

ANHP76 292 22 22 103 58 58

.

Figure 5 - Application of heat-sink paste before welding

Figure 6 - Maximum static forces and moments

LIQUID INJECTION OIL COOLING

The liquid injection system provided on the unit is self-con-

tained but requires the connection of the liquid line sized as

shown in the table.

Loading...

Loading...