6112628-UIM-B-0622

Johnson Controls Ducted Systems 11

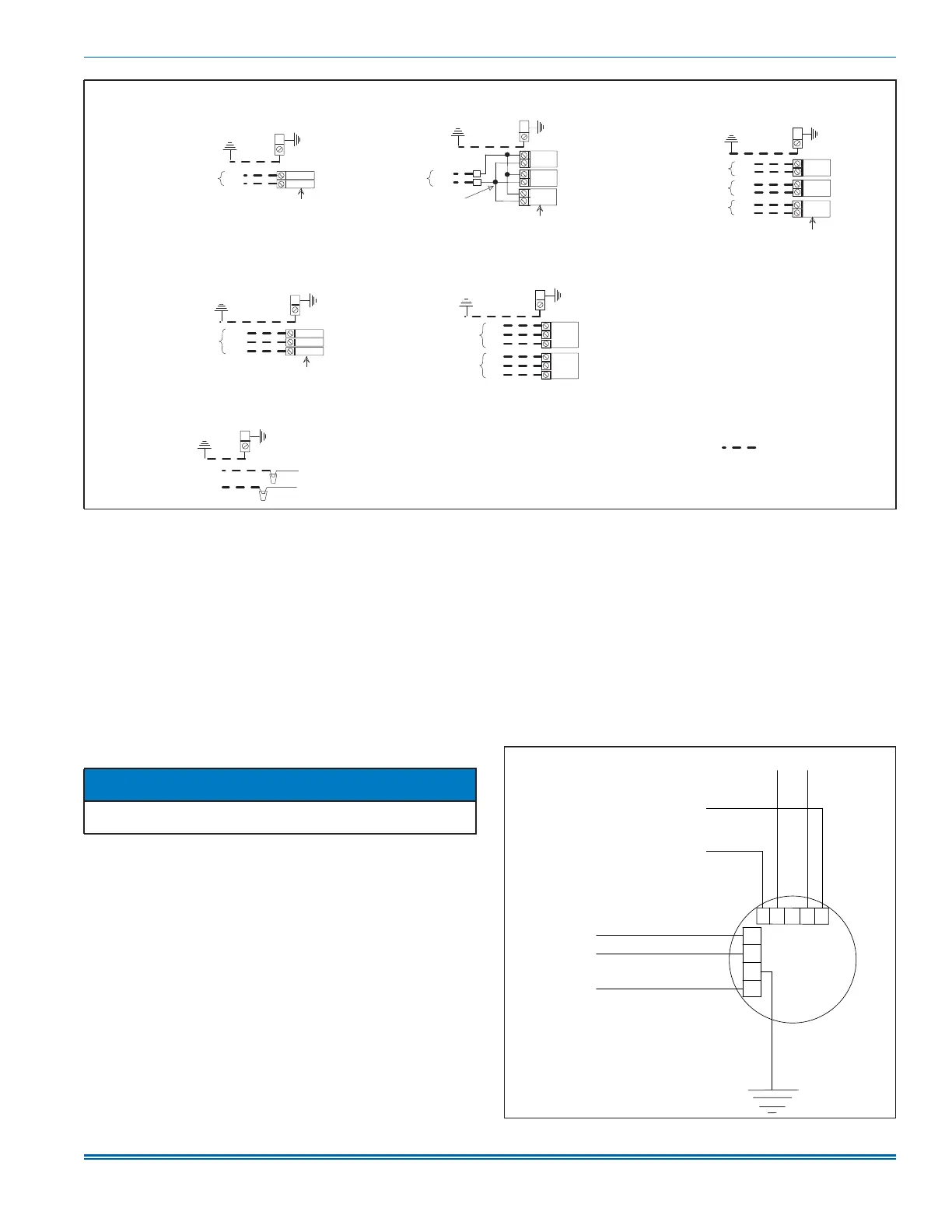

Section X: Low voltage control connections

The 24 V power supply is provided by an internally wired low voltage

transformer that is standard on all models. If connecting the unit to a 208

V power supply, the low voltage transformer must be rewired to the 208 V

tap. See the Wiring diagram.

Field-supplied low voltage wiring can exit the unit through the top right

(when unit is vertical upflow) or the right side panel. See Figure 3.

Remove the knockout and pierce the foil faced insulation to allow wiring

to pass through. Use as small of a hole as possible to minimize air leak-

age. Install a 7/8 in. plastic bushing in the selected hole and keep low

voltage wiring as short as possible inside the control box.

To further minimize air leakage, seal the wiring entry point at the outside

of the unit. Connect the field wiring at the pigtails supplied with the air

handler. See Figure 20 to Figure 28 for system wiring.

Section XI: Blower speed connections

Adjust the blower motor speed to provide airflow within the minimum and

maximum limits approved for indoor coils, electric heat, and outdoor

units. Make speed tap adjustments at the motor terminal block.

See Table 13 for airflow data. Connect the motor wires to the motor

speed tap receptacle for the speed required.

The standard ECM motor operates when a 24 VAC signal is sent to any

of its five speed taps. If simultaneous 24 VAC inputs are present, the

motor operates at the highest speed tap that is energized. The lowest

speed is one and the highest speed is five.

The air handler comes factory-wired with the electric heat kit connected

to tap five for the heating speed. There are two speed tap wires for cool-

ing or heat pump blower speeds. The YEL/BLK wire is for first stage com-

pressor speed and the YEL wire is for full compressor speed. The RED

continuous fan speed wire is connected to speed tap one. If the lowest

speed tap (tap one) is needed for first stage compressor speed, leave the

continuous fan speed wire connected to speed tap one and let the room

thermostat provide the signal (through its G output) for first stage

compressor, as the room thermostat provides a fan output during a heat

pump heating or cooling call. In this particular application, cap off the

YEL/BLK wire and do not use it.

Move the electric heat kit wire for the heating speed from tap five to the

appropriate speed tap according to Table 5. If electric heat requires

speed tap five, the highest speed tap available for cooling or heat pump

heating is tap four. Do not splice or combine multiple signals to a single

blower motor tap. Each of the standard ECM blower motor speed taps

have a built-in 60 s off delay.

The circulating blower (green) thermostat input is factory connected to

speed tap one, which is the lowest speed. The circulating blower (yellow)

thermostat input is used for the second-stage or full blower speed. See

Figure 20 to Figure 28 for wiring details.

Figure 15: Line power connections

.

A1699-001

3

2

1

GND

SD

SD

SD

GND

GND

CKT

L1

L2

L1

L2

SD

SD

SD

CKT

CKT

2

1

L1

L2

L3

L1

L2

L3

L1

L2

L3

GND

CN

CN

CKT

CKT

SD

SD

GND

GND

L1

L2

L1

L2

L1

L2

Two circuits on 15 kW to 20 kW

Three circuits on 25 kW

Field power wiring

(208/230 V)

Component Codes:

GND - Ground lug

SD - Service disconnect

CKT - Circuit

CN - Wire connector/nut

1 Phase Electric Heat Power Options:

3 Phase Electric Heat Power Options:

Single source power

Power supply Power supply Power supply

Terminal block or service disconnect

Jumper bar

Two circuits on 15 kW to 20 kW

Three circuits on 25 kW

Multi-source power with jumper bar Multi-source power

No Electric Heat:

Power supply

Single source power Multi-source power

Power supply

Terminal block or service disconnect

Power supply

NOTICE

All wiring must comply with local and national electrical code require-

ments. Read and heed all unit caution labels.

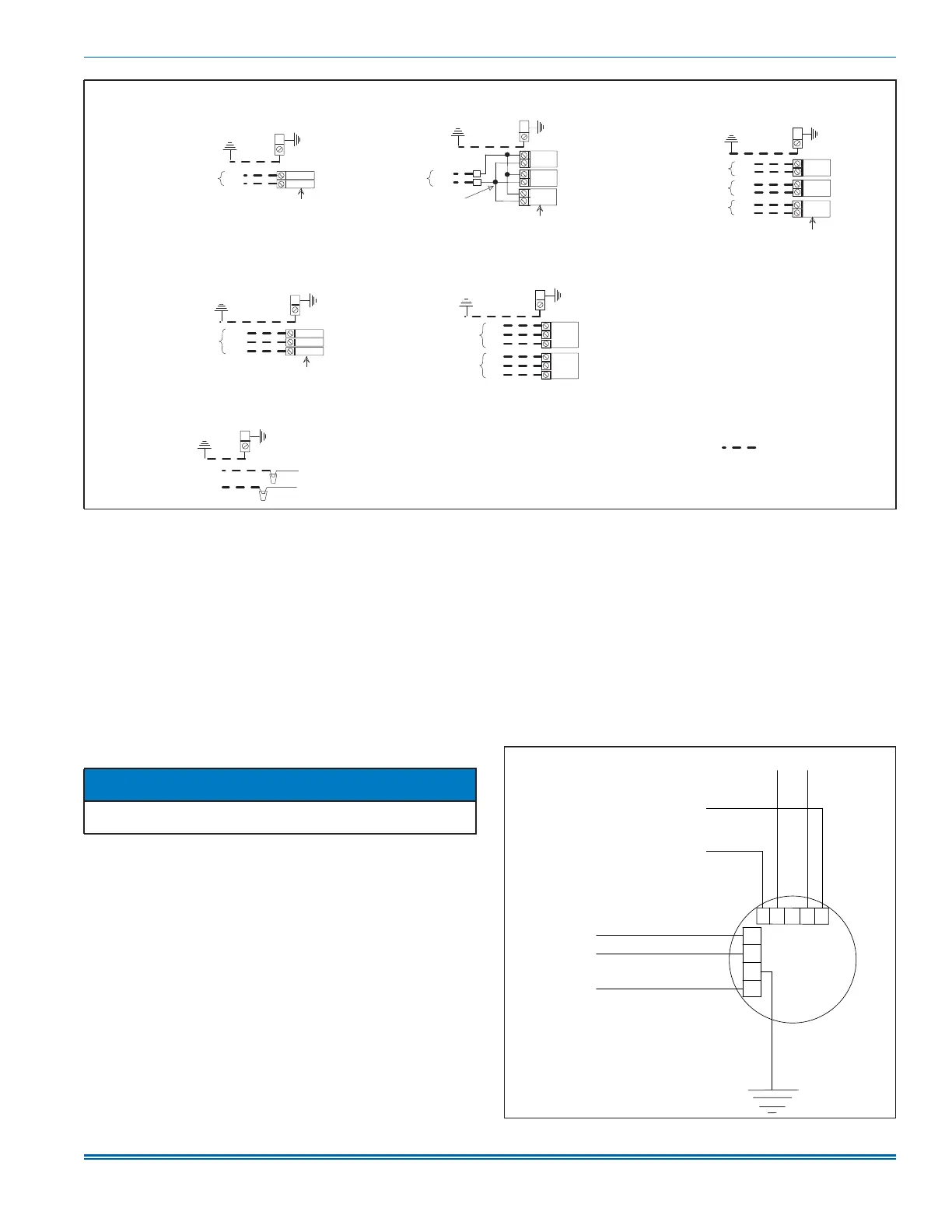

Figure 16: Blower speed connections

GRN

Blower

motor

C

L

G

N

RED/WHT

BLK/WHT

BLU/WHT

RED

To resistor

YEL

BLK

Standard ECM - high efficiency motor

A1772-001

123 45

YEL/BLK

To 230 V on

transformer

To common

on transformer

To resistor

Loading...

Loading...