6112628-UIM-B-0622

8 Johnson Controls Ducted Systems

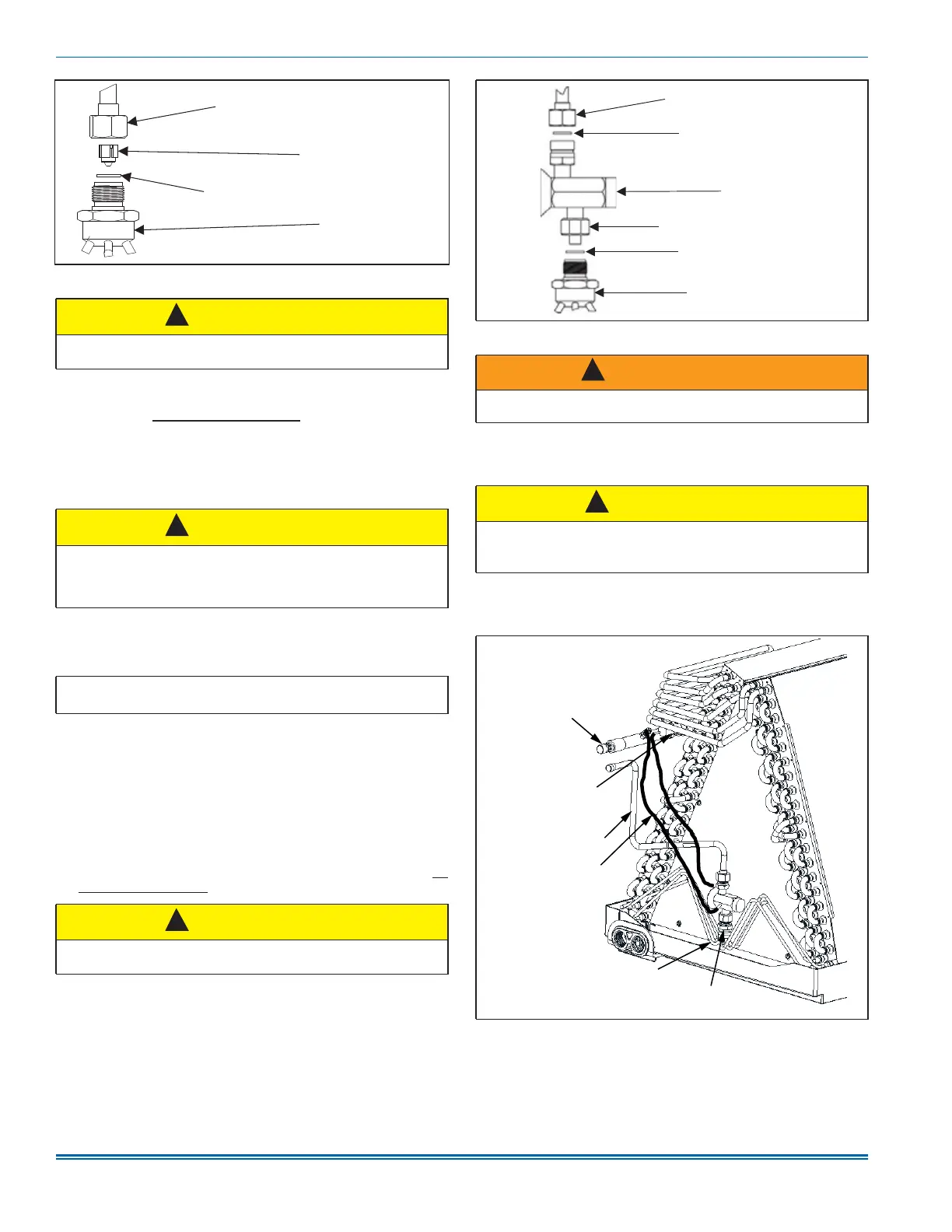

8. After the piston is installed, install the liquid line to the top of the pis-

ton/distributor assembly. Hand tighten and turn an additional 1/4

turn to seal.

Do not over tighten fittings.

9. Replace the black plastic cap on the unused equalizer fitting con-

nection port.

10. After installing the refrigeration piping, leak test the system.

Thermal expansion valve (TXV) installation

The following are basic steps for installation. For detailed instructions,

refer to the Installation Manual accompanying the TXV kit. Complete

the following steps to install the TXV kit:

1. Relieve the holding charge by depressing the Schrader valve core

on the suction manifold stub out.

2. After discharging the holding charge completely, loosen and

remove the Schrader valve core.

3. Place a backup wrench on the distributor, then loosen and remove

the brass distributor nut. Retain the brass nut for use on the liquid

line. Keep the PTFE washer in place and discard the seal disk.

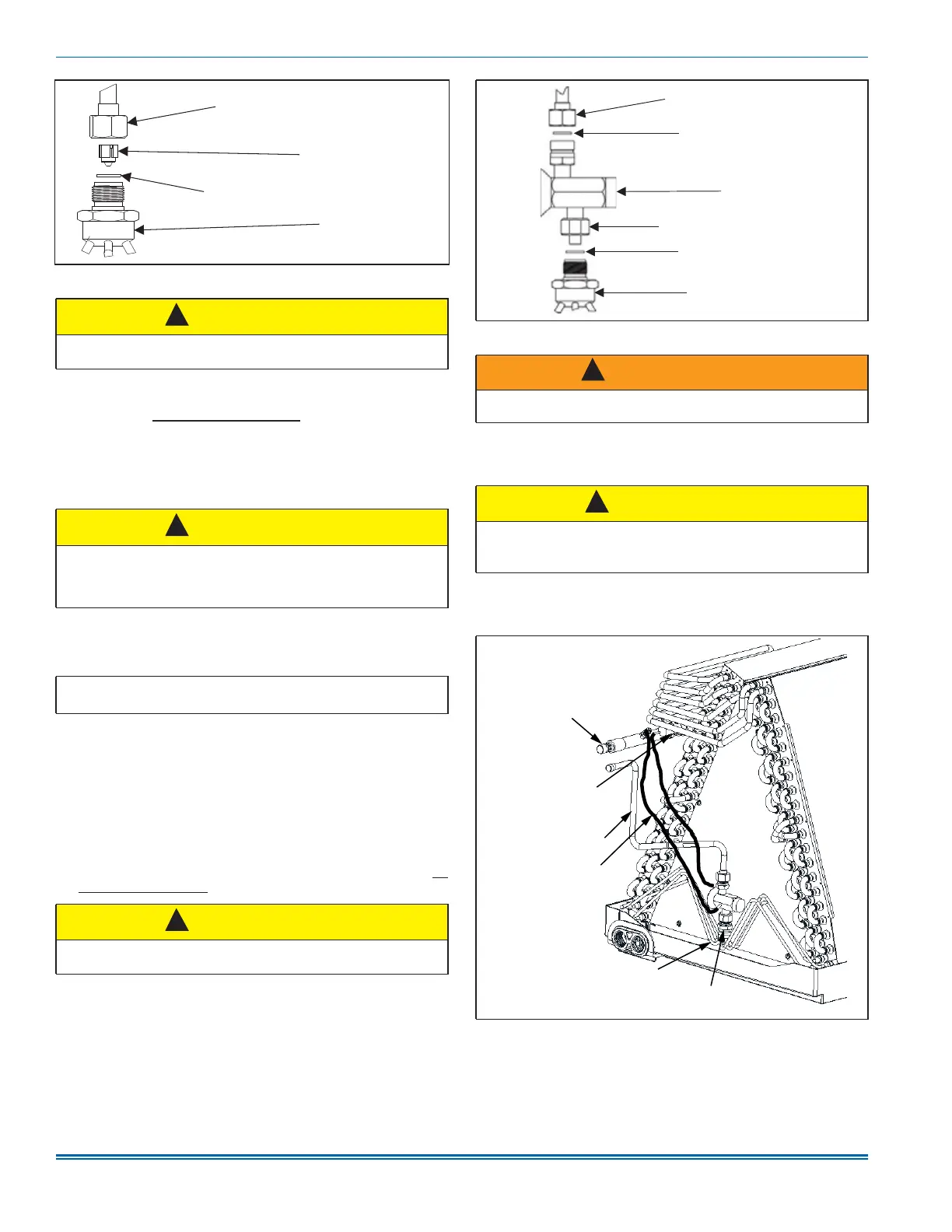

4. Install the thermal expansion valve into the distributor assembly

with the supplied fittings. Ensure the PTFE washer is seated in the

distributor. Hand tighten and turn an additional 1/4 turn to seal. Do

not over-tighten fittings. See Figure 11.

5. Slide the nut removed in Step 3 over the supplied liquid line. Place

the supplied PTFE washer from the TXV kit in place on the TXV

and install the liquid line into the top of the thermal expansion valve.

Adjust the assembly so the liquid line aligns with the hole in the

access panel. See Figure 12. Hand tighten the liquid line and apply

an additional 1/4 turn to seal.

6. Install the TXV equalizer line onto the vapor line by hand tightening

the 1/4 in. SAE coupling nut to the equalizer fitting and apply an

additional 1/3 turn to seal. See Figure 12.

7. Route the temperature sensing bulb tube for the TXV toward the

vapor line header and the TXV equalizer tube connection port on

the vapor line header.

8. Install the TXV bulb to the vapor line near the TXV equalizer tube

connection port, using the bulb clamps supplied with the TXV

assembly. Ensure the bulb makes maximum contact. See Figure

12 and Figure 13, and complete the following steps:

Figure 10: Piston installation

CAUTION

Do not overtorque. Do not use slip joint pliers. This will distort the alu-

minum distributor and the brass fitting (potentially causing leaks).

CAUTION

Outdoor unit model numbers ending with an H have a factory installed

hard start kit which is required when a TXV is installed. Outdoor unit

model numbers with no H ending do not require a hard start kit unless

the outdoor unit Data Sheet indicates it.

Important: Refer to the Technical Guide or Data Sheet for the unit to

determine the correct TXV kit to use on this product.

CAUTION

Do not overtorque. Do not use slip joint pliers. This will distort the alu-

minum distributor and the brass fitting (potentially causing leaks).

A0305-003

Distributor

Piston

Liquid line swivel coupling

(This ¿WWLQJLVDULJKWKDQGHGWKUHDG

TXUQFRXQWHUFORFNZLVHWRUHPRYH

PTFE ZDVKHU

!

!

!

Figure 11: TXV installation

WARNING

The Schrader valve core must not be installed with TXV installation.

Poor system performance or system failure could result.

CAUTION

In all cases, mount the TXV temperature sensing bulb after the vapor

line is brazed and sufficiently cooled.

Failure to use a suction line split grommet may result in TXV failure.

Figure 12: TXV bulb and equalizer line installations

A0281-004

TXV/distributor coupling

Liquid line/TXV coupling

PTFE washer

TXV

PTFE washer

Distributor

!

!

Indoor coil header assembly

(header body)

TXV bulb

(wrap with

insulation)

Liquid line

TXV equalizer line

Distributor body

Thermal expansion valve (TXV)

A1671-001

Loading...

Loading...