P470 Electronic Pressure Control with Display Product/Technical Bulletin 7

Changing Setpoint Values and Anti-short

Cycle Delay Time-Interval

Follow these steps to change the P470 control setpoint

values and anti-short cycle delay time-interval:

1. Press the Menu button once and the display

changes to a flashing ci1 (Cut-in Setpoint 1).

• If you want to change Cut-in Setpoint 1,

proceed to Step 3.

• If you want to change another setpoint value or

the anti-short cycle delay time-interval,

proceed to Step 2.

Note: After 30 seconds of inactivity, the control

reverts to the operating pressure display.

2. Press the Up button once to go to Cutout Setpoint

1 (co1). Press the Up button again to go to

Cut-in Setpoint 2 (ci2), and again to go to Cutout

Setpoint 2 (co2), and once more to go to anti-

short cycle delay (ASd).

• You may press the Up button again to go back

to Cut-in Setpoint 1, or press the Down button

(repeatedly) to scroll through the parameters in

reverse order.

3. Once the parameter you want to change is flashing

on the display, press the Menu button once. The

current pressure setpoint value (or delay time-

interval) is displayed.

4. Press the Up or Down button to change the

setpoint value (or time-interval).

5. Press the Menu button to save the new value. The

display then returns to the operating pressure

display.

Note: If the Menu button is not pressed within

30 seconds after changing a setpoint or time-

interval value, the control reverts to the previously

programmed setpoint or time interval value.

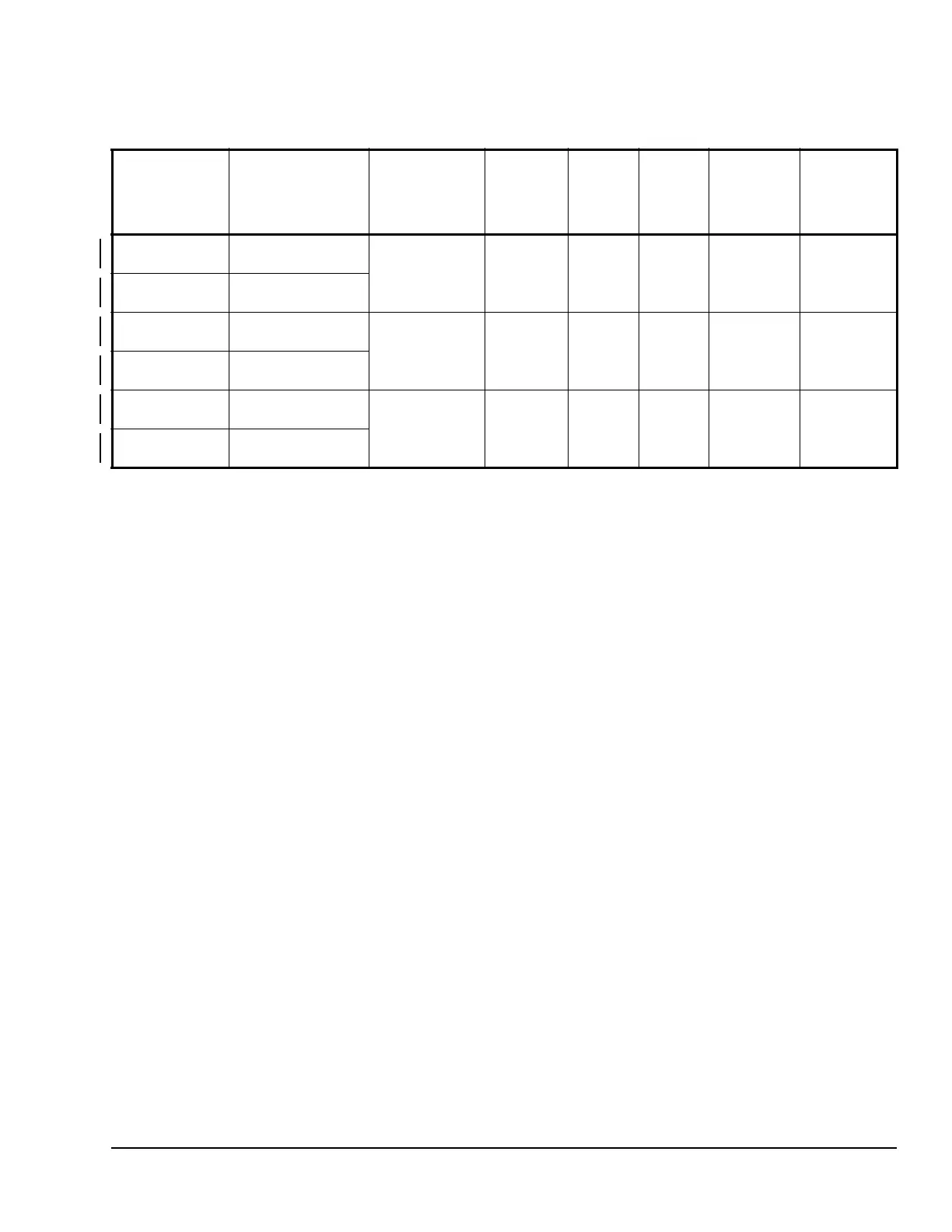

Table 2: Specified Transducer Models, Required Jumper Positions with the Resulting Operating Pressure

Ranges, and Factory Settings at Startup

Transducer

Model

Number

1

Pressure

Connection

Fitting

Required

P6 Jumper

Positions

Control’s

Operating

Pressure

Range

Factory

Set

Cut-in

2

(in psi)

Factory

Set

Cutout

2

(in psi)

Minimum

Setpoint

Differential

Factory Set

Setpoint

Differential

P499RAP-101C

P499RAP-101K

1/8 in. NPT Male JMP1 Removed

JMP2 Removed

0–100 psi S1-40

S2-45

S1-20

S2-25

5 psi 20 psi

P499RCP-101C

P499RCP-101K

1/4 in. SAE Female

(Schrader® Fitting)

P499RAP-105C

P499RAP-105K

1/8 in. NPT Male JMP1 Installed

JMP2 Removed

0–500 psi S1-250

S2-220

S1-190

S2-160

20 psi 60 psi

P499RCP-105C

P499RCP-105K

1/4 in. SAE Female

(Schrader Fitting)

P499RAP-107C

P499RAP-107K

1/8 in. NPT Male JMP1 Removed

JMP2 Installed

50–750 psi S1-250

S2-220

S1-190

S2-160

20 psi 60 psi

P499RCP-107C

P499RCP-107K

1/4 in. SAE Female

(Schrader Fitting)

1. C suffix is transducer (only). K suffix is transducer with 2 meter long wiring harness.

2. S1 = Primary Setpoint Value and S2 = Secondary Setpoint Value.

Loading...

Loading...