P470 Electronic Pressure Control with Display Product/Technical Bulletin8

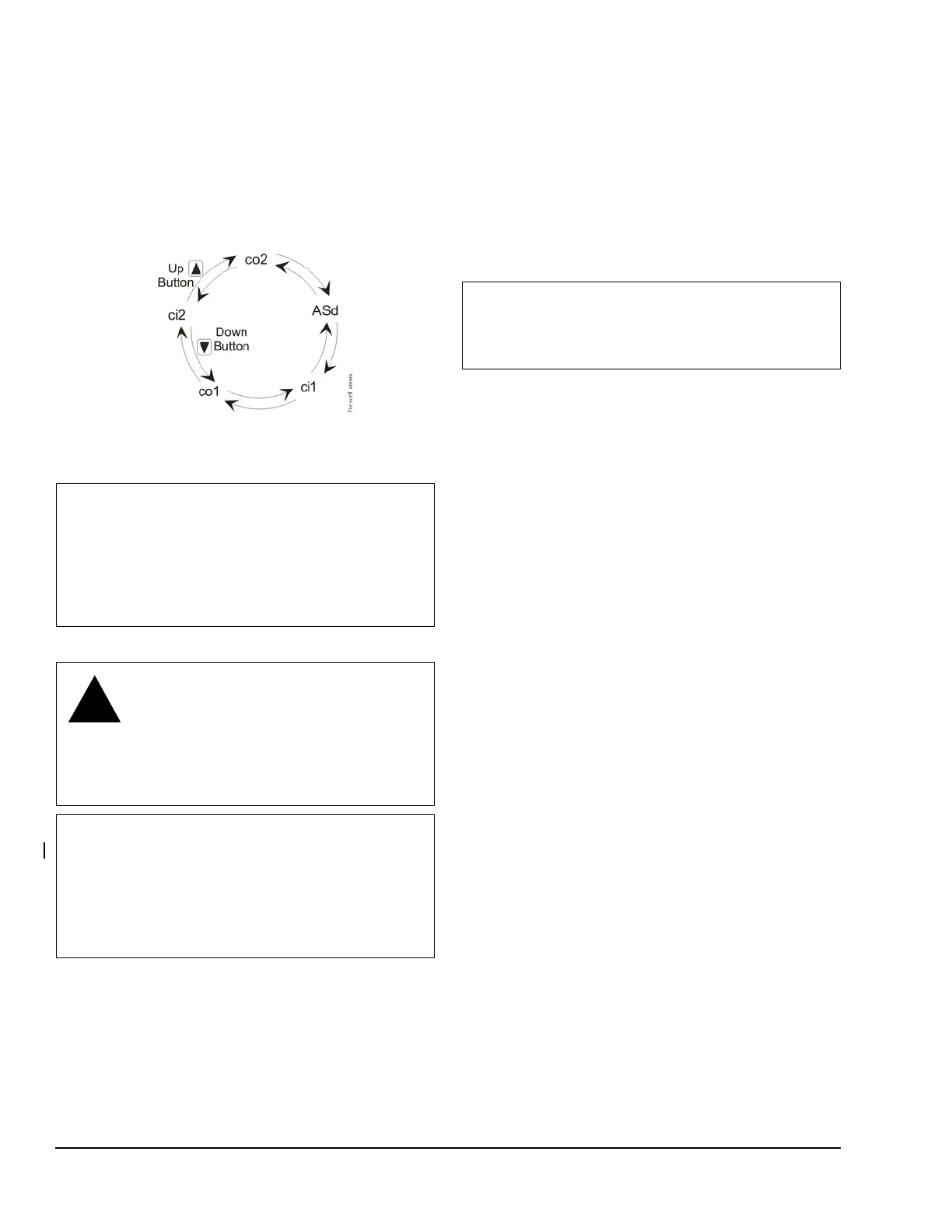

Scrolling through the Adjustable Setpoints

Figure 10 illustrates the order of the adjustable

setpoints displayed when scrolling through them using

the Up or Down buttons. Press the Up button to scroll

through and display the adjustable setpoints in a

clockwise direction. Press the Down button to scroll

through and display the adjustable setpoints in a

counterclockwise direction.

Troubleshooting

Determine what the proper supply voltage is for the

control you are troubleshooting. See Figure 4,

Figure 5, and Figure 6 for the wiring diagram and

terminal designations for the control.

See Figure 3 and Table 3 for more information about

displayed codes (error codes) that appear on the LCD.

On dual control applications, disconnect one control

and check each control as a single control application

using the following procedures. See Figure 7.

Equipment Needed

• An accurate and reliable pressure gauge

connected near the transducer.

• A reliable and accurate Digital Voltmeter (DVM)

capable of measuring AC voltage and DC voltages

down to ± 0.1 VDC in the 0–10 VDC range.

1. Check for proper supply voltage to the control.

a. Before powering control and equipment, check

that all of the wiring is correct and all of the

connections are tight.

b. Apply power to the control.

c. With the DVM, check the voltage between the

control’s supply power terminals: T1 and T2 for

the low-voltage model, and AC COM and 120V

or 240V for the line voltage model.

• For low-voltage controls powered by a 24 VAC

Class 2 transformer, select AC volts on the

DVM. The supply voltage must be between

20–30 VAC.

• For line-voltage controls, select AC volts on the

DVM. The supply voltage must be between

102–132 VAC for controls powered at the 120V

and COM terminals, and between 177–264

VAC for controls powered at the 240V and

COM terminals.

d. If the voltage reading is within the specified

voltage range, proceed to Step 2.

e. If the DVM reading is not within the indicated

voltage ranges, replace the 24 VAC Class 2

transformer or check the line voltage power

source and provide for proper power to the

control.

f. Recheck for proper supply voltage.

2. Check for proper supply voltage to the pressure

transducer.

a. Select DC volts on the DVM and measure the

voltage (VDC

S

) between 5VDC and the COM

terminals on the terminal block on the upper

left side of the control.

IMPORTANT: Before applying power to the control

and controlled equipment, make sure installation,

wiring, and control settings are according to the

application requirements. Then power the

equipment and observe the controlled equipment for

at least three complete operating cycles before

leaving the installation.

WARNING: Risk of Electric Shock.

Do not touch any exposed metal parts

with anything other than properly

insulated tools or insulated probes of the

digital voltage meter. Failure to use

properly insulated tools and probes may

result in severe personal injury or death.

IMPORTANT: The P470 pressure control and

P499 transducer are not field repairable. Perform

the following procedures, in the order they are

presented, to determine the problem. If the problem

is with the control or transducer, contact a

Johnson Controls/PENN sales representative for a

replacement.

Figure 10: Order of the Adjustable Setpoints and

Time Delay Interval

IMPORTANT: The control and the controlled

equipment must be powered and operating at a

stable pressure to perform many of the following

procedures.

Loading...

Loading...