P470 Electronic Pressure Control with Display Product/Technical Bulletin 9

b. The voltage must be 5.0 VDC (± 0.2 VDC).

If the voltage is in this range, proceed to

Step 3.

• If the voltage is out of this range, power down

the controlled equipment and disconnect it

from the control. Disconnect the transducer

from the control. With the control powered,

measure the voltage (VDC

S

) between the

5VDC and COM terminals on the terminal

block on the upper left side of the control.

• The voltage must be 5.0 VDC (± 0.2 VDC).

If the voltage is in this range, replace the

transducer. If the voltage is out of range,

replace the P470 control.

3. Check pressure transducer for proper output signal

voltage.

a. Measure and record the voltage (V

o

) between

the SEN and the COM terminals on the control

terminal block.

b. At the same time, observe and record the

pressure reading (psi

T

) on the gauge.

c. The transducer output signal voltage (V

o

)

increases proportionally with an increase in the

pressure at the transducer (psi

T

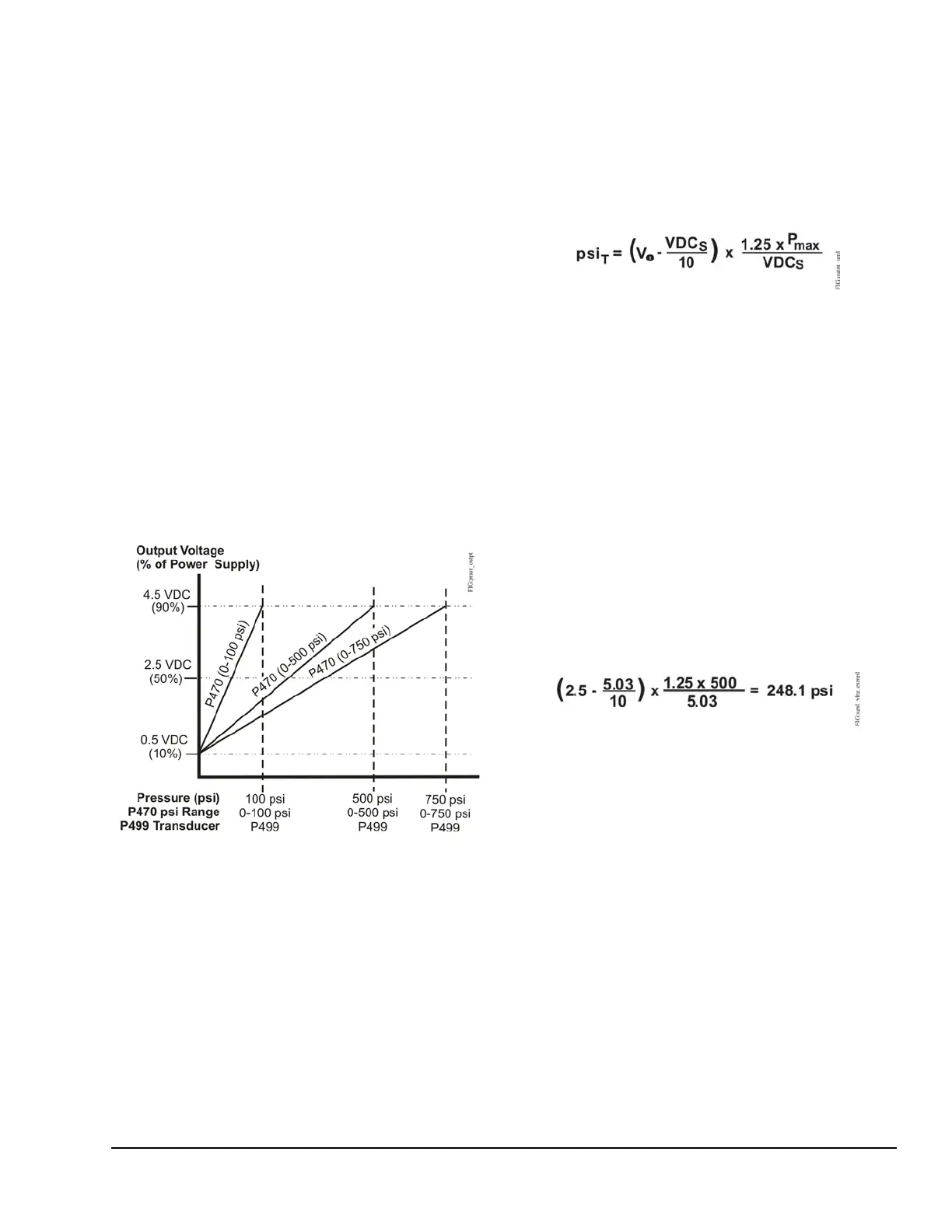

). Use the

graph in Figure 11 to compare the measured

signal voltage to the measured pressure or use

the formula below to compare the voltage and

pressure values.

psi

T

= Pressure measured at transducer

V

o

= Transducer output signal voltage (VDC)

VDC

S

= Supply voltage to the transducer

(measured in Step 2a).

P

max

= Transducer pressure range maximum

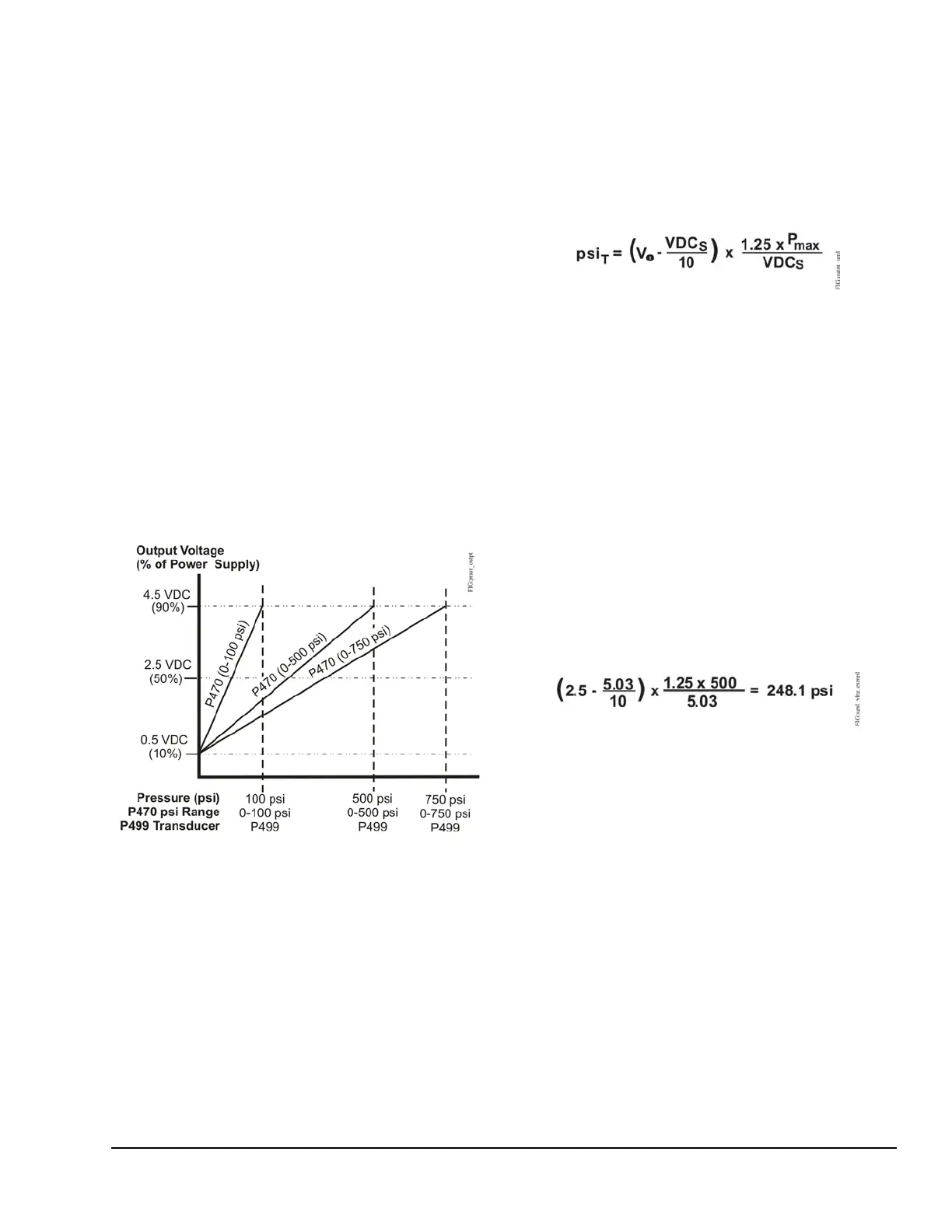

Example:

The measured pressure at the gauge is

approximately 245 psi (psi

T

), the measured

transducer output voltage is 2.5 VDC (V

o

), the

measured supply voltage to the transducer is

5.03 VDC (VDC

S

), and the transducer’s rated

range is 0 to 500 psi (P

max

). Use the formula

above to calculate the pressure you would expect

from the measured voltage.

Since the measured pressure, psi

T

(245 psi), is

close to the pressure (248.1 psi) calculated from

the measured voltage, the transducer output

voltage is considered acceptable.

Note: Depending on the accuracy of the

instrumentation used to measure the actual

pressure at the transducer (psi

T

) and the

transducer output voltage (V

o

), the actual and

calculated pressure may not exactly agree.

4. Check the control for proper operation.

Perform Steps 1-3 first.

Note: The pressure range jumpers must be

positioned to operate the control in a pressure

range that is compatible with the transducer used.

See Table 2.

Figure 11: Pressure vs. Output Voltage

Figure 12: Output Signal Voltage

Figure 13: Output Signal Voltage Example

Loading...

Loading...