P470 Electronic Pressure Control with Display Product/Technical Bulletin10

Note: When the LED is lit, the output relay should

be energized and the N.O. contacts should be

closed.

Note: Use the minimum differential value for the

selected operating pressure range. See Table 2.

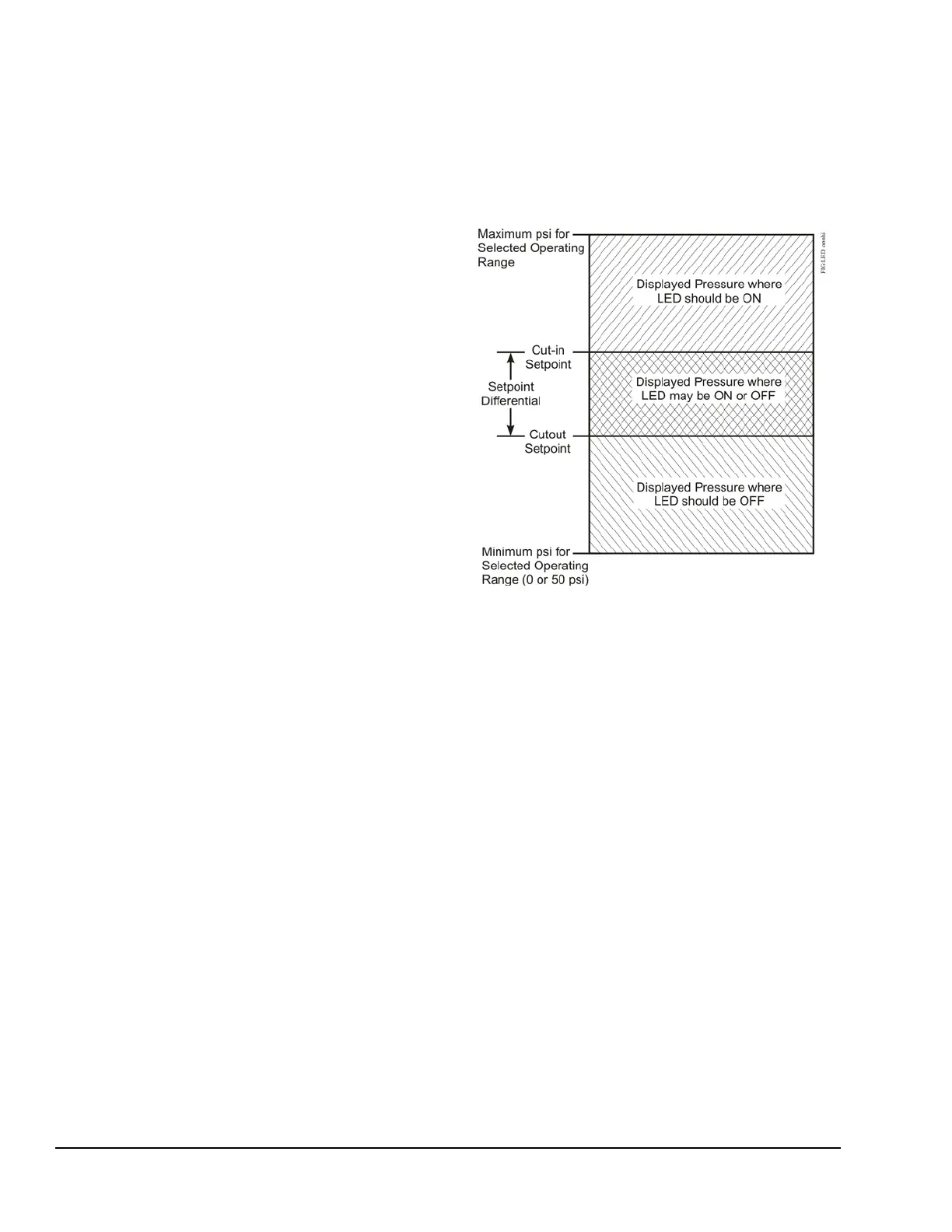

Note: The following procedures change the cut-in

and cutout setpoints and shift the setpoint

differential so the displayed pressure is not within

the Setpoint Differential range. See Figure 14 and

Figure 15.

a. Set the P470 control’s anti-short cycle delay to

0 (zero), and make sure that the control is

operating on the primary setpoints (S1).

b. Disconnect power to the controlled equipment

and allow the pressure in the unpowered

equipment to stabilize at a pressure of 30 psi

or more above the minimum pressure for the

selected operating pressure range.

c. Disconnect the wires from the P470 control’s

output relay, and make sure the control is

powered.

d. The pressure displayed on the control should

equal the pressure measured at the transducer

with a pressure gauge. If the two pressure

value differ greatly, check the gauge for

accuracy. If the gauge checks out, replace the

control and recheck display and measured

pressure.

e. (See Figure 14.) If the control is operating as

an open-high control and:

• The LED is Off. Increase cutout setpoint

above the displayed pressure by the minimum

differential pressure (for the selected operating

pressure range) plus 10 psi. Then increase the

cut-in setpoint above the displayed pressure

by 5 psi. The LED should go On (and the N.O.

contacts close).

• The LED is On. Decrease cut-in setpoint

below the displayed pressure by the minimum

differential pressure plus (for the selected

operating pressure range) 10 psi. Then

decrease the cutout setpoint below displayed

pressure by 5 psi. The LED should go Off

(and the N.O. contacts open).

f. For example, if the control and transducer are

setup for a 0–100 psi pressure range with a

40 psi cut-in setpoint and a 50 psi cutout, and

the displayed pressure is 47 psi, the LED may

be On or Off. Adjust the cutout up to 62 psi (or

higher) and the cut-in up to 52 psi (or higher).

The LED should be On. Then adjust the cut-in

down to 32 psi (or lower) and the cutout down

to 42 psi (or lower). The LED should go Off.

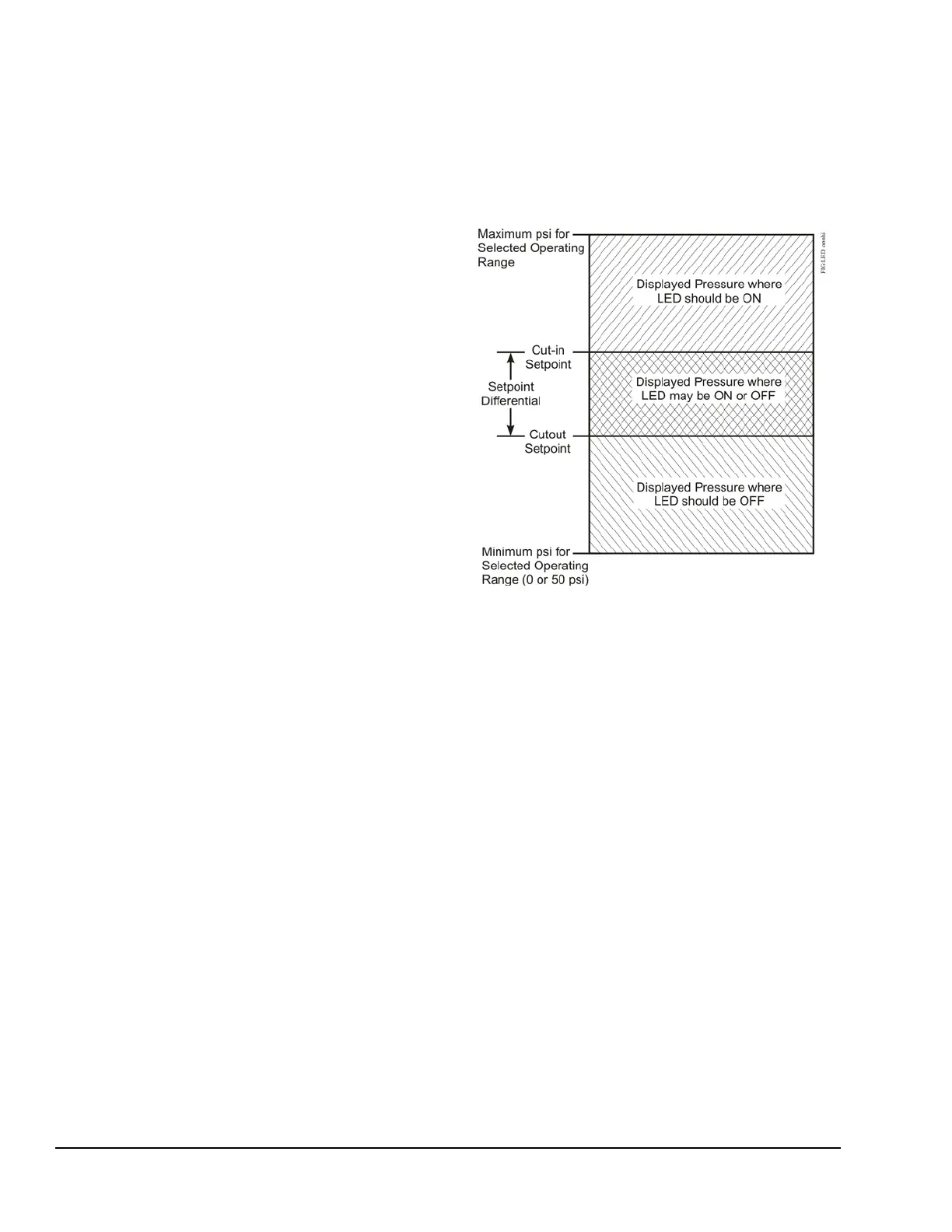

g. This procedure, in effect, moves the

crosshatched areas shown on the graphs in

Figure 14 and Figure 15 above or below the

displayed pressure, and forces the LED to go

On or Off (and output relay to close or open)

and verifies the control is functioning properly.

(See Figure 15.) If the control is operating as

an open-low control and:

• The LED is Off. Decrease cutout setpoint

below the displayed pressure by the minimum

differential pressure (for the selected operating

pressure range) plus 10 psi. Then decrease

the cut-in setpoint below the displayed

pressure by 5 psi. The LED should go On (and

the N.O. contacts close).

Figure 14: LED Status for Open-High Controls

Loading...

Loading...