RL SERIES INSTALLATION MANUAL

1/2'' Pitch

Figure 5: Unit Pitch for DrainFigure 4: Suggested Layout of Condensate

Installing Horizontal Units cont.

ABCD

Front Front Back Back

Model Return / Discharge Left Right Right Left

Left / Side or End 30% 26% 22% 22%

Right / Side or End 26% 30% 22% 22%

Approximate

080 - 120

A

B

C

D

Controls

Horizontal Unit Corner Weight Distribution

Duct System

An air outlet collar is provided on vertical top flow units and all horizontal units to facilitate a duct connection. A flexible connector is recom-

mended for discharge and return air duct connections on metal duct systems. Uninsulated duct should be insulated with a minimum of

1-inch duct insulation. Application of the unit to uninsulated ductwork in an unconditioned space is not recommended as the unit’s perfor-

mance will be adversely affected.

If the unit is connected to existing ductwork, check the duct system to ensure that it has the capacity to accommodate the air required for

the unit application. If the duct is too small, as in the replacement of heating only systems, larger ductwork should be installed. All existing

ductwork should be checked for leaks and repaired if necessary.

The duct system should be sized to handle the design airflow quietly and efficiently. To maximize sound attenuation of the unit blower, the

supply and return plenums should include an internal duct liner of fiberglass or constructed of ductboard for the first few feet. On systems

employing a sheet metal duct system, canvas connectors should be used between the unit and the ductwork. If air noise or excessive

airflow is a problem, the blower speed can be changed.

Water Piping

The proper water flow must be provided to each unit whenever the unit operates. To assure proper flow, use pressure/temperature ports to

determine the flow rate. These ports should be located at the supply and return water connections on the unit. The proper flow rate cannot

be accurately set without measuring the water pressure drop through the refrigerant-to-water heat exchanger.

All source water connections on commercial units are fittings that accept a male pipe thread (MPT). Insert the connectors by hand, then

tighten the fitting with a wrench to provide a leakproof joint. When connecting to an open loop (groundwater) system, thread any copper

MPT fitting into the connector and tighten in the same manner as described above.

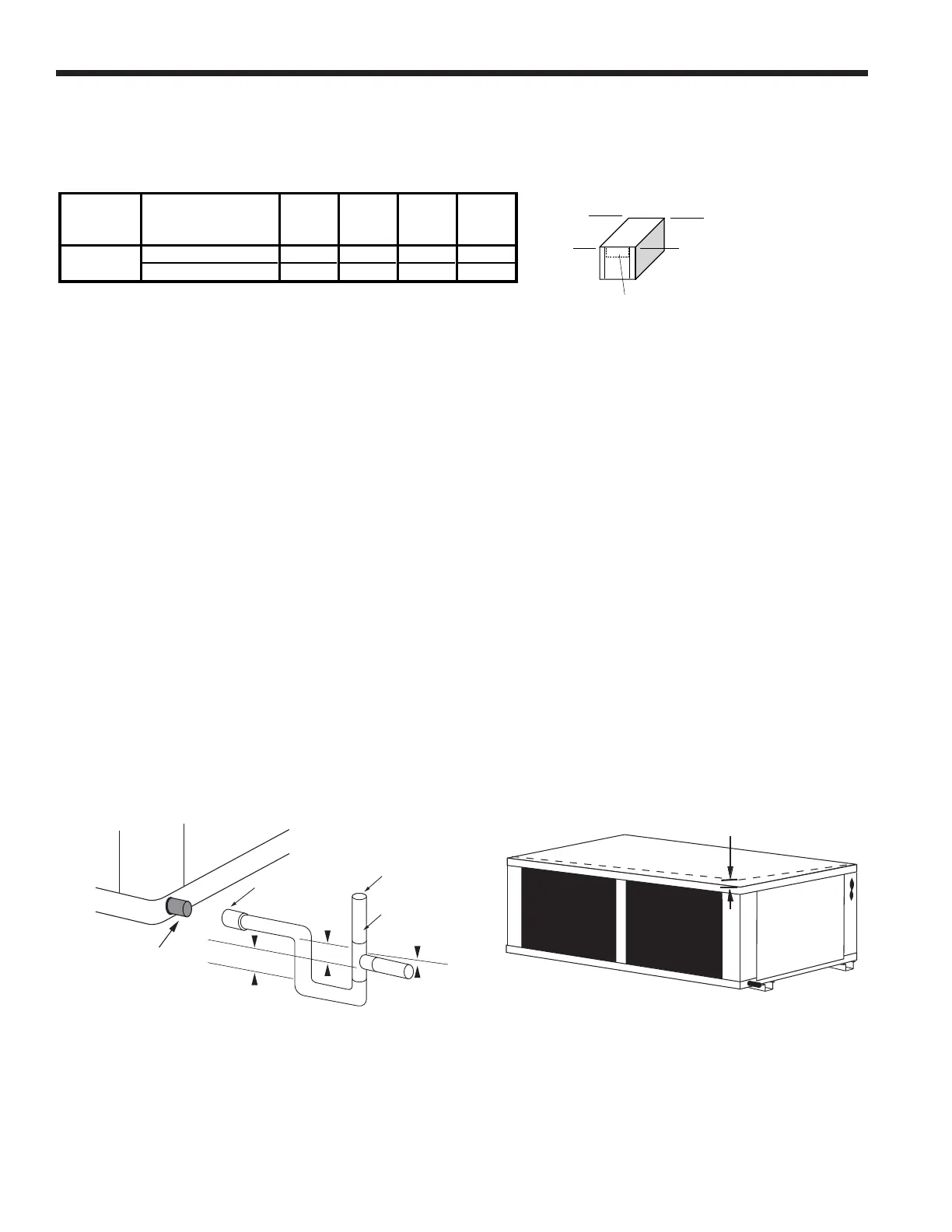

1.5 in.

1.5 in.

3/4 in. PVC tube stub

3/4 in. PVC

Coupling

Vent (if needed)

3/4 in. PVC

1/8 in. per foot

Loading...

Loading...