Piping connections

The outdoor condensing unit must be connected to the

indoor evaporator coil using field-supplied refrigerant

grade (ACR) copper tubing that is internally clean and

dry. Units must be installed only with the tubing sizes for

approved system combinations as specified in the Tabular

Data Sheet. The charge given is applicable for total tubing

lengths up to 15 ft (4.6 m). Refer to the Piping Application

Guide (P/N 24077) for installing tubing of longer lengths

and elevation differences.

NOTICE

Using a larger than specified line size could result

in oil return problems. Using too small a line results

in loss of capacity and other problems caused by

insufficient refrigerant flow. Slope horizontal vapor

lines at least 1 in. (2.5 cm) every 20 ft (6.1 m) toward

the outdoor unit to facilitate adequate oil return. If

more than the 80 ft line length is necessary, facilitate

correct refrigerant velocity with adjusted line diameter

in accordance with the Piping Application Guide (P/N

24077).

CAUTION

This system uses R-410A refrigerant, which operates

at higher pressures than R-22. No other refrigerant

may be used in this system. Gauge sets, hoses,

refrigerant containers, and the recovery system must

be designed to handle R-410A. If you are unsure,

consult the equipment manufacturer.

WARNING

Never install a suction-line filter-drier in the liquid line

of an R-410A system. Failure to follow this warning

can cause a fire, injury or death.

Precautions during line installation

• Install the lines with as few bends as possible. Be

careful not to damage the couplings or kink the

tubing. Use clean hard drawn copper tubing where no

appreciable amount of bending around obstruction is

necessary. If soft copper must be used, be careful to

avoid sharp bends, which may cause a restriction.

• Install the lines so that they do not obstruct service

access to the coil, air handling system, or filter.

• Isolate the refrigerant lines to minimize noise

transmission from the equipment to the structure.

• Insulate the vapor line with a minimum of 3/8 in.

foam rubber insulation (Armaflex or equivalent).

Also insulate liquid lines that are exposed to direct

sunlight, high temperatures, or excessive humidity.

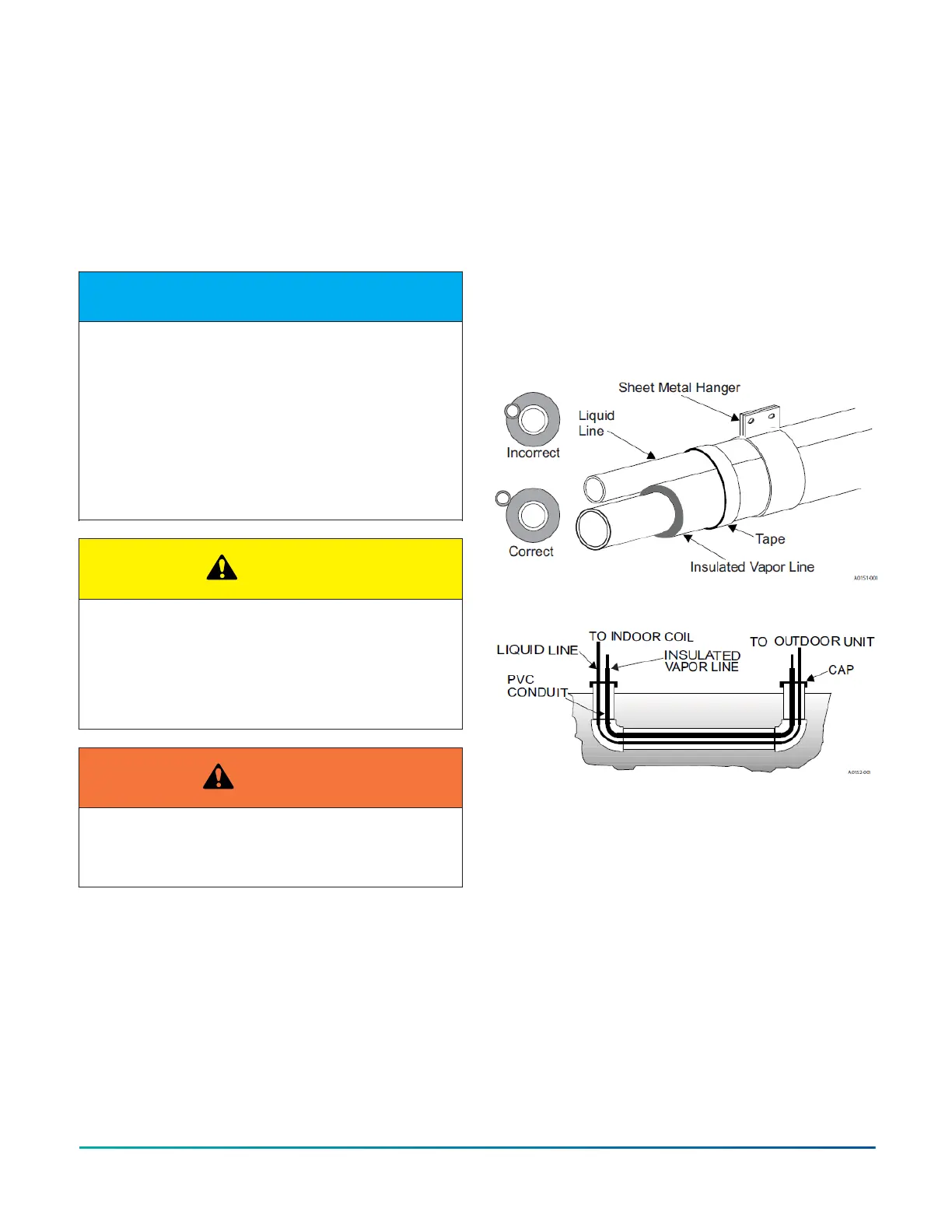

• Tape and suspend the refrigerant lines as shown in

Figure 5. Do not allow tube metal-to-metal contact.

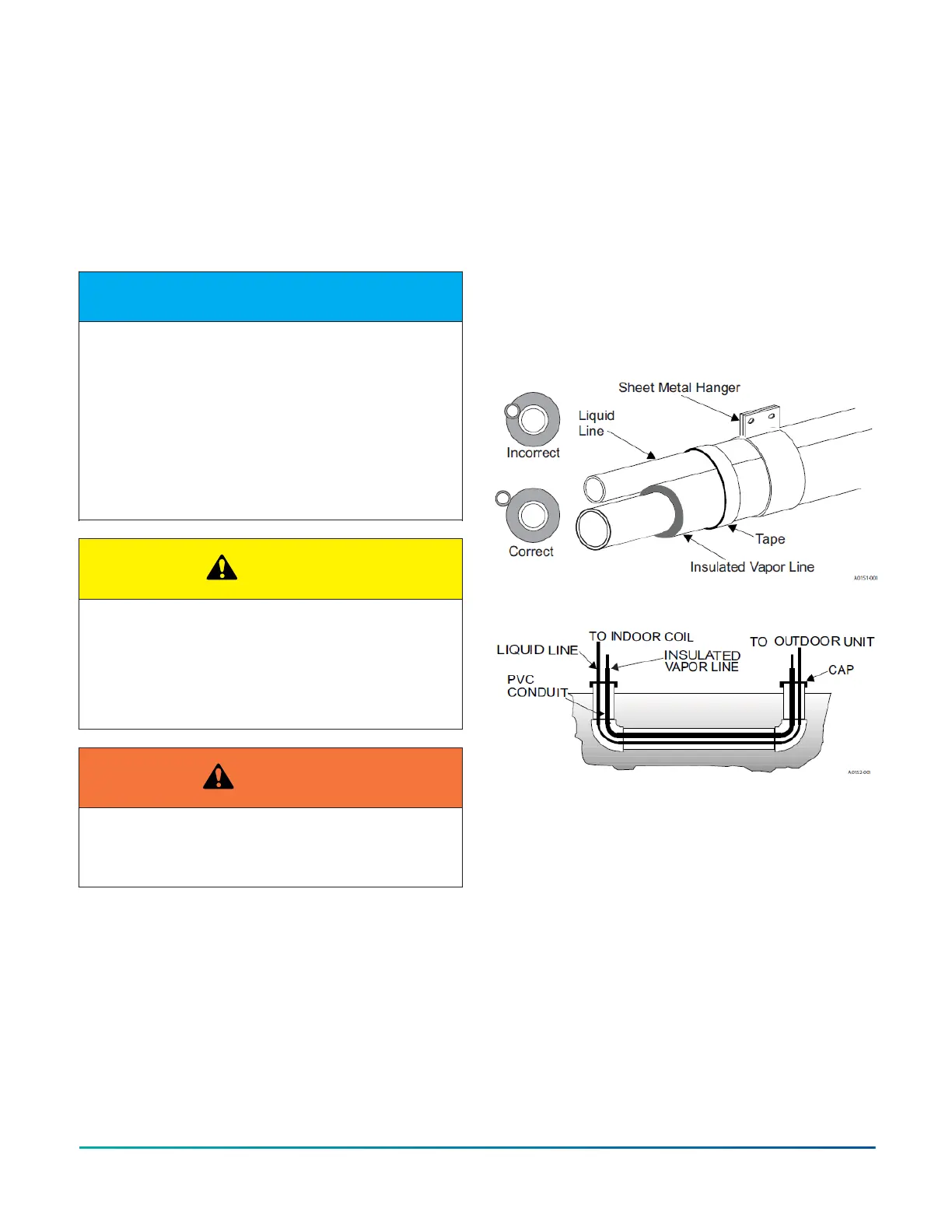

• Use PVC piping as a conduit for all underground

installations as shown in Figure 6. Keep buried lines

as short as possible to minimize the build up of liquid

refrigerant in the vapor line during long periods of

shutdown.

Figure 5: Installation of vapor line

Figure 6: Underground installation

• Pack fiberglass insulation and a sealing material such

as permagum around refrigerant lines where they

penetrate a wall to reduce vibration and to retain

some flexibility.

• For systems with total line length exceeding 75 ft

(22.86 m), refer to the Piping Application Guide (P/

N 24077) for vapor and liquid line sizing, calibration

of liquid line pressure loss or gain, determination

of vapor line velocity, elevation limitations, TXV

connections, system charging or traps.

Precautions during brazing of lines

All outdoor unit and indoor coil connections are copper-

to-copper and must be brazed with a phosphorous-

copper alloy material such as Silfos-5 or equivalent. Do

not use soft solder. The outdoor units have reusable

service valves on both the liquid and vapor connections.

The total system refrigerant charge is retained within

Installation Manual: R-410A Outdoor Split-System Air Conditioner 9

Johnson Controls Ducted Systems

Loading...

Loading...