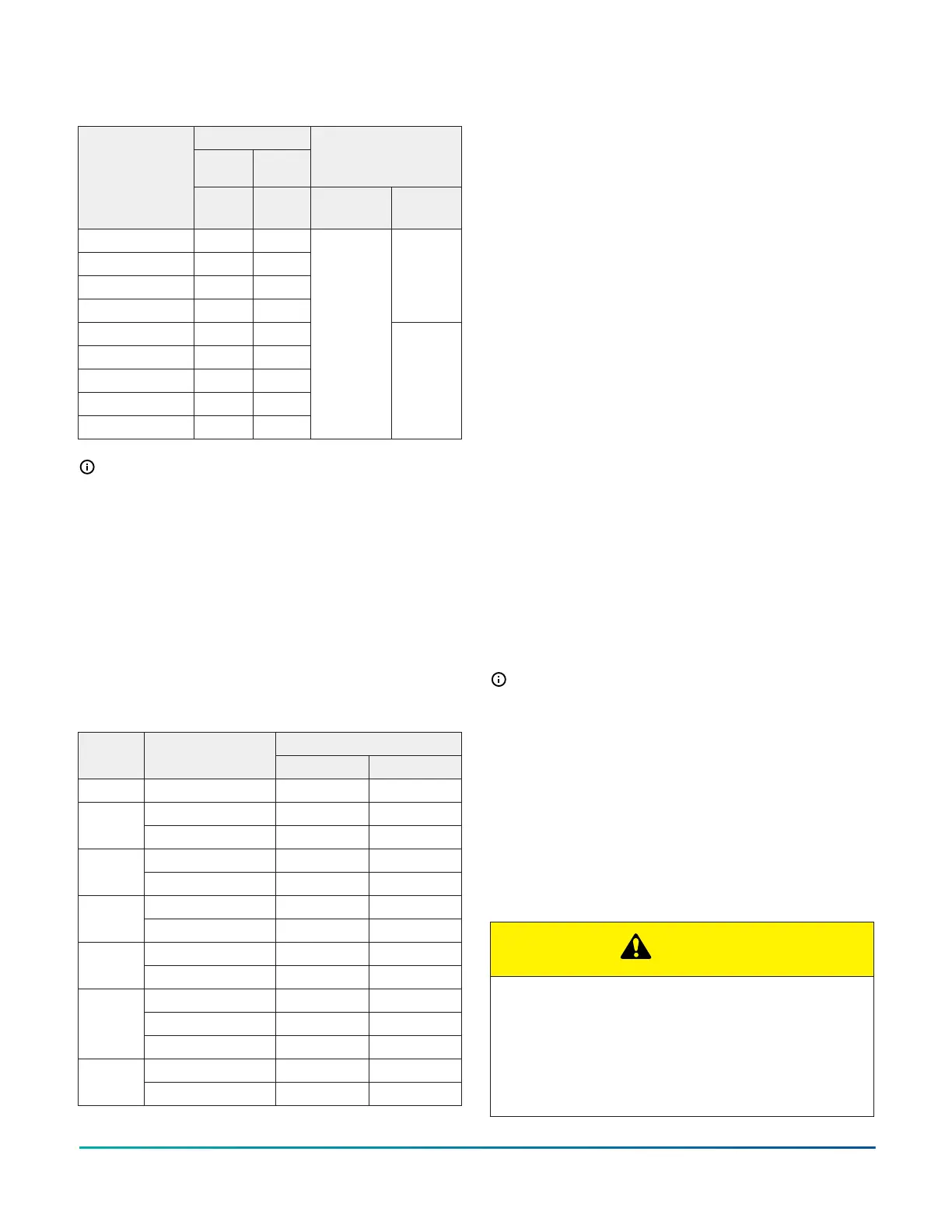

Table 3: Dimensions - XAU uncased upflow or

downflow coil

Dimensions

Height Width

Refrigerant

connections

line size

Models

A (in.) B (in.)

Liquid

(in.)

Vapor

(in.)

XAUA18AXXN1 16 5/8 13

XAUA24BXXN1 18 3/4 13

XAUB30CXXN1 21 1/4 16

XAUB36DXXN1 21 1/2 16

3/4

XAUC42EXXN1 23 19 1/2

XAUC48FXXN1 25 19 1/2

XAUC60GXXN1 29 1/4 19 1/2

XAUD60GXXN1 28 3/4 23

XAUD60HXXN1 33 23

3/8

7/8

Note:

• Refrigerant line sizes may require larger lines

for extended line lengths. Refer to application

data part number 247077.

• The adapter fitting must be field installed for

any refrigeration piping sizes not shown in the

table.

• Refer to the Technical Guide for the outdoor unit

for the proper refrigeration piping size.

Limitations

Install the coil in accordance with all national and local

safety codes. See Table 4.

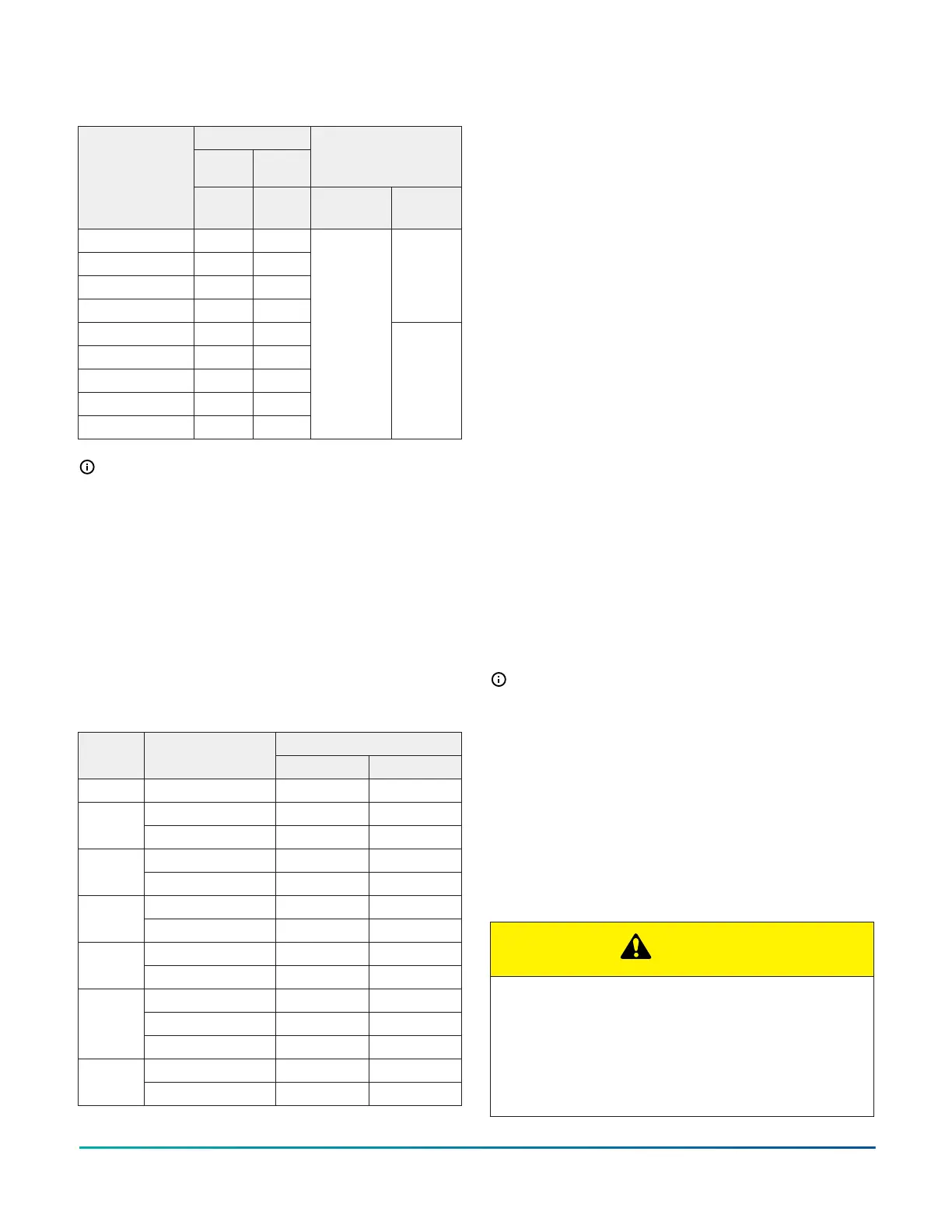

Table 4: Coil airflow limits

CFM limits

Coil size

Outdoor

unit (ton)

Minimum Maximum

18 1 1/2 525 675

1 1/2 525 675

24

2 700 900

2 700 900

30

2 1/2 875 1125

2 1/2 875 1125

36

3 1050 1350

3 1050 1350

42

3 1/2 1225 1575

3 1050 1350

3 1/2 1225 157548

4 1400 1800

4 1600 1800

60

5 1750 2250

Installation overview

1. Before installation, review the installation aids

available in Installation verification. During

installation, use the installation aids to verify that

tasks are completed as required. See Figure 7 for an

overview of components and their location.

2. Install the coil metering device as required. See

Using a coil metering device.

3. Install the coil. See Installing the coil: XAF and XAH

coils or Installing the coil: XAU coils.

4. Connect the duct system. See Connecting the duct

system.

5. Connect the condensate drain lines. See Connecting

the condensate drain.

6. Connect the refrigerant lines. See Connecting

refrigerant lines.

7. Clean the coil. See Cleaning the coil.

8. Check and adjust airflow as required. See Adjusting

the air system.

9. Instruct the homeowner as needed. See Instructing

the homeowner.

Using a coil metering device

You must install a piston or TXV (flex coil models) in the

field, unless you are using a coil with a factory installed

TXV or a coil equipped with an electronic expansion valve

(EEV). See Using a coil equipped with an EEV: XAF and XAH

coils. Refer to the Technical Guide for outdoor units for

information on the piston or TXV required for the indoor

coil. It is best practice to install the piston or TXV kit before

installing the coil and brazing the refrigeration piping.

Note: Do not install the TXV sensing bulb until you

have completed the brazing and the piping has

cooled.

For TXV installation, refer to the Installation Manual

provided with the TXV kit and see Installing a TXV.

For piston installation, see Installing a piston. The piston

and the Schrader valve core are supplied with the outdoor

unit if applicable. Some outdoor sections require a TXV. If

using a piston instead of a TXV, install the Schrader valve

core in the suction line equalizer connection port and cap

the Schrader valve core with the plastic cap supplied. Do

not install the Schrader valve core if a TXV is installed,

because the TXV equalizer line attaches to the equalizer

connection port or suction line port.

CAUTION

COIL UNDER PRESSURE

Verify that pressure has been released by depressing

Schrader valve core shown in Figure 1 and Figure

2. The coil requires a metering device to be added.

Refer to outdoor unit documentation for correct TXV

or piston to be used.

Installation Manual: XAF, XAH, and XAU Series - Full Cased and Uncased Coils for Cooling and Heat Pumps12

Johnson Controls Ducted Systems

Loading...

Loading...