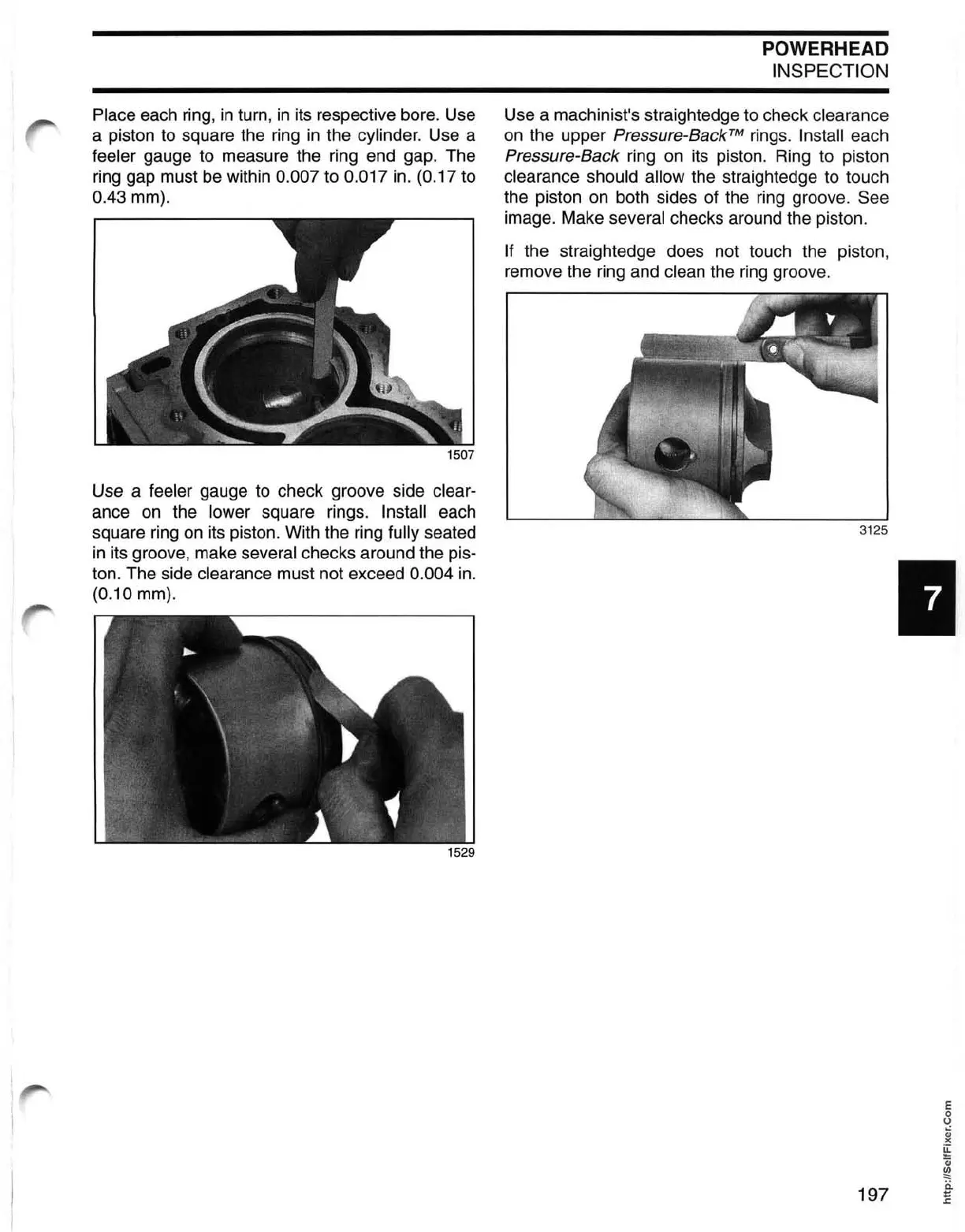

Place each ring,

in

turn,

in

its respective bore. Use

a piston to square the ring

in

the cylinder. Use a

feeler gauge to measure the ring end gap. The

ring gap must be within

0.007 to 0.017 in. (0.17 to

0.43 mm).

Use a

feeler gauge to check groove side clear-

ance on the lower square rings. Install each

square ring

on

its piston. With the ring fully seated

in

its groove, make several checks around the pis-

ton. The side

clearance must not exceed 0.004 in.

(0.10 mm).

1529

POWERHEAD

INSPECTION

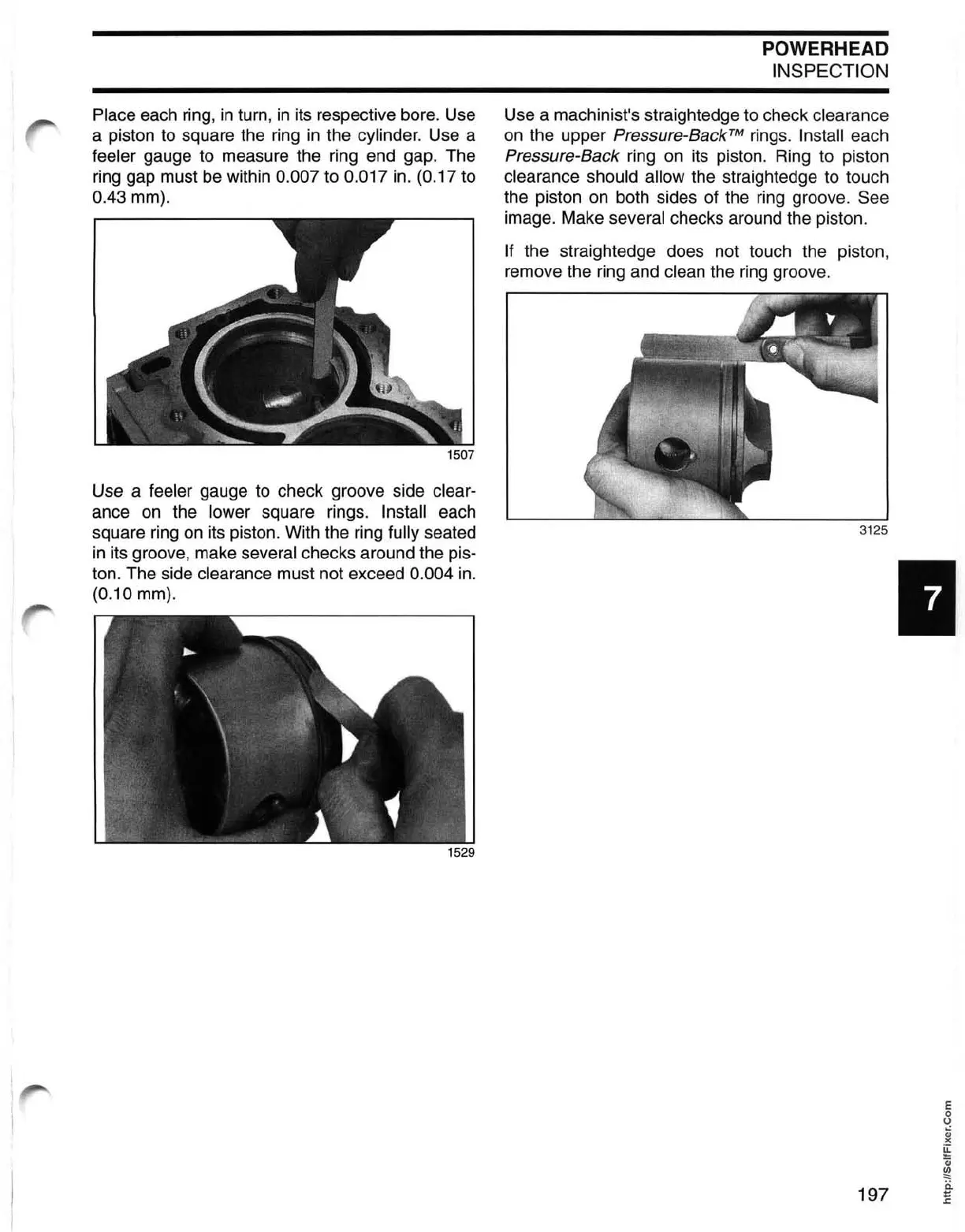

Use a machinist's straightedge to check clearance

on the upper Pressure-Back™ rings. Install each

Pressure-Back ring on its piston. Ring to piston

clearance should allow the straightedge to touch

the piston on both sides of the ring groove.

See

image. Make several checks around the piston.

If the straightedge does not touch the piston,

remove the ring and clean the ring groove.

3125

197

Loading...

Loading...