Chapter - Optional Equipment

Page Issue 02

OG

4:2

V Range 501 ● 651 ● 801 - Operator’s Guide

The Combivac nozzle contains a rotating brush and may allow higher sweeping speeds in certain

working conditions.

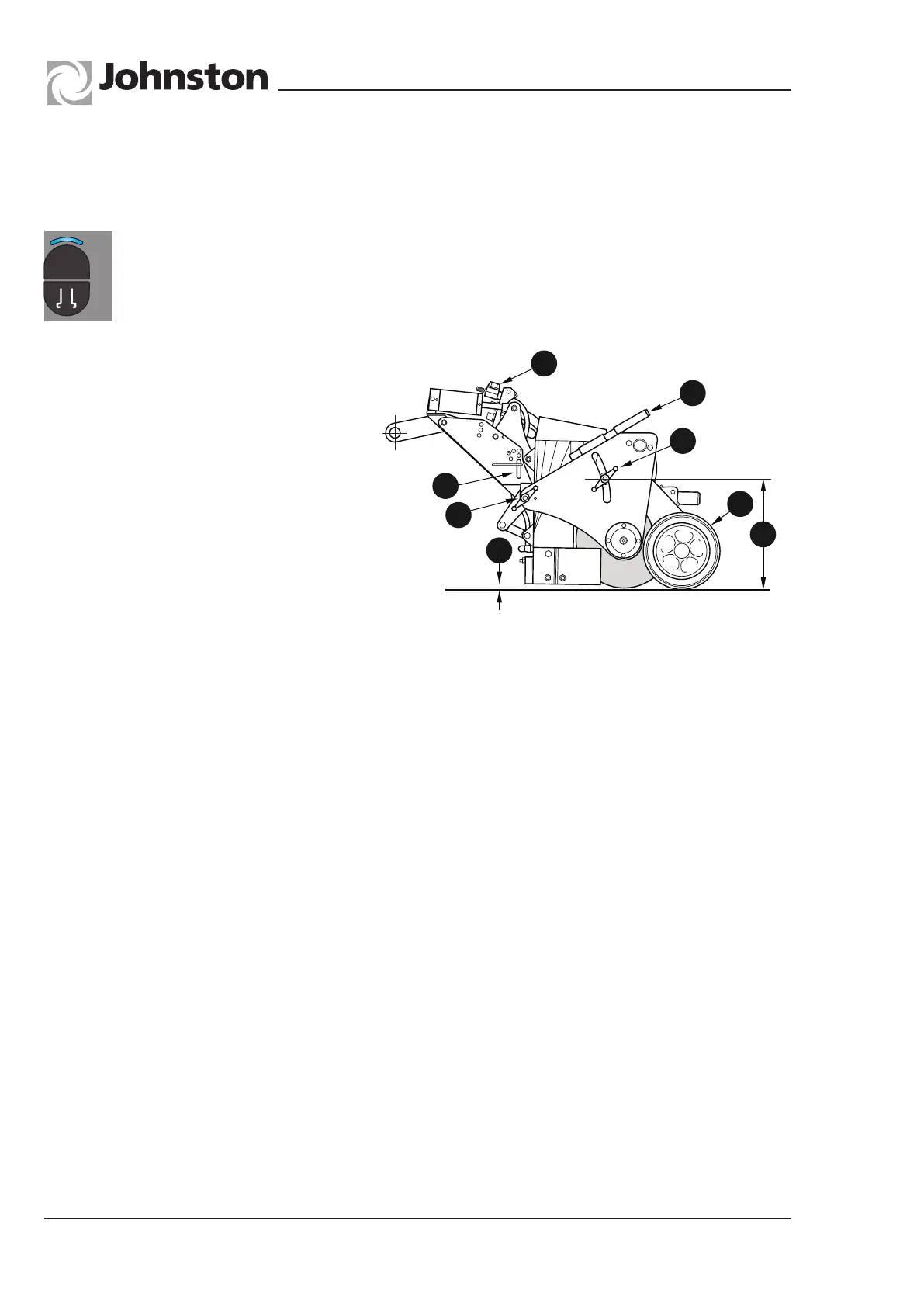

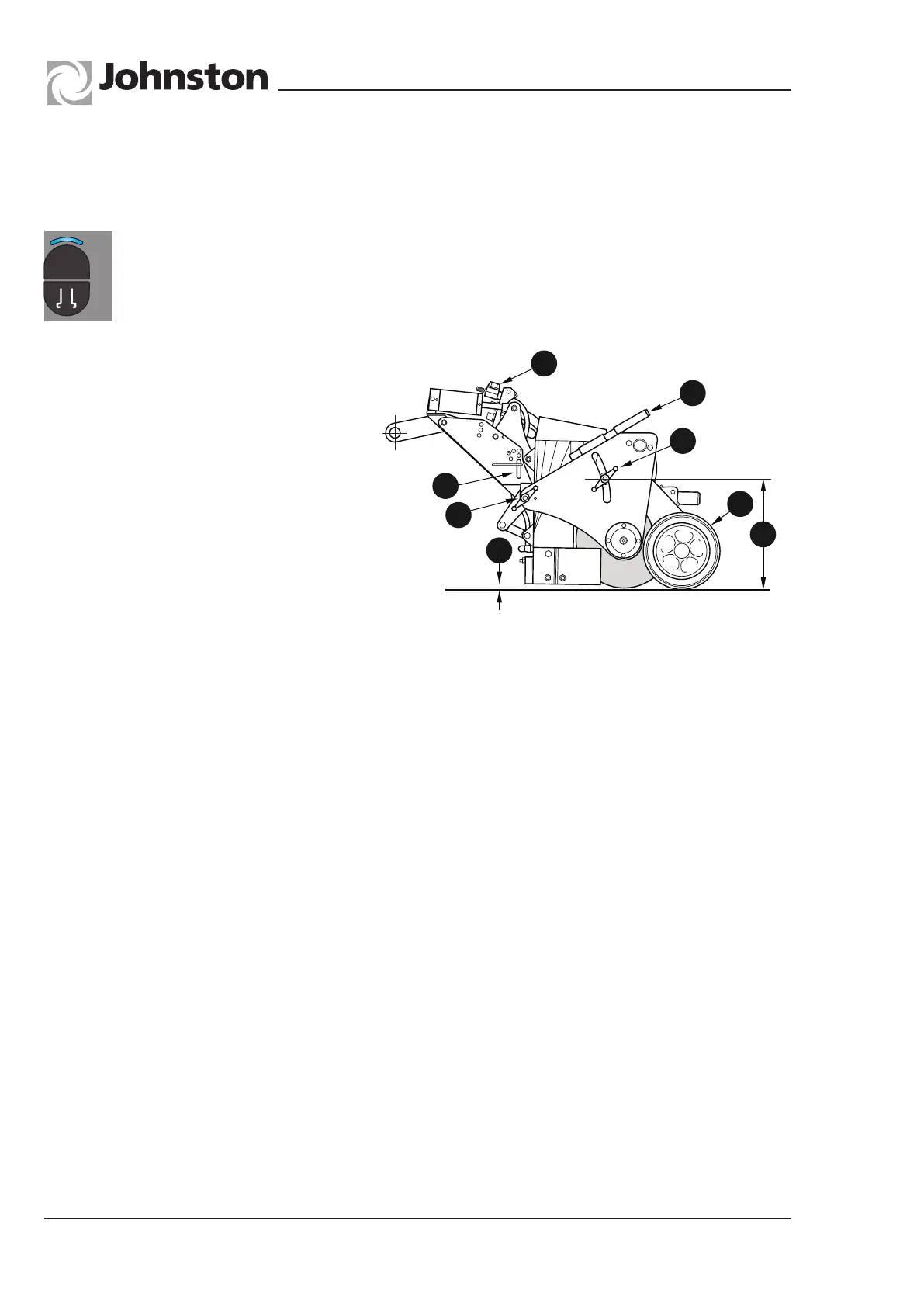

The Combivac Nozzle features four

water jets as standard, two of which can

be isolated by turning off the manual tap

(G) at the front of the nozzle drawbar.

The pressure of the brush on the road is

achieved by loosening hand nuts (C) and

(D) and raising or lowering by use of the

handle (B). The normal nozzle opening

(F) is controlled by moving pin (A) up or

down the adjustment holes to achieve

the desired opening (nominal 30mm).

To Operate Nozzle With Brush

Lower nozzle, release hand nuts (C) and (D) and lower brush to obtain the desired pressure

on the road. Retighten nuts (C) and (D).

To operate without brush

Lower nozzle, release hand nuts (C) and (D) and raise the brush assembly using the handle

(B). Retighten nuts (C) and (D). Brush should be above the road surface.

NozzleWheelAdjustment

The nozzle wheel (E) is adjustable to compensate for wear. Ensure the dimension (H) is

365mm when a new brush is fitted.

ToAdjustOperatingHeight

Lower nozzle and operate maxigap. This will remove tension from pin (A). The pin can be

moved to the desired hole to set the minimum nozzle opening required.

To Change Brush Segments

i) Lower nozzle to ground. Remove the outer brush carrier plate by removing the two M10

setscrews from the cross tube and the two hand nuts.

ii) Raise the nozzle and withdraw the brush stock.

iii) Undo the end plate of the stock and replace brush segments. On re-assembling, remember

to fit a spacer at each end of the stock.

iv) Refitting is the reverse of the above procedure.

M02OG-104

A

B

C

D

G

E

H

F

COMBIVAC NOZZLE OPTION

Water sprays; - ON/OFF Illuminated when selected

Nozzle; - ACTIVE/STOWED - Nozzle lowers and brush rotates intake flaps open

automatically

A

All Copyright and rights are the property of Johnston Sweepers Ltd

Loading...

Loading...